Information injection-pump assembly

ZEXEL

106672-4780

1066724780

KOMATSU

6128711202

6128711202

Rating:

Cross reference number

ZEXEL

106672-4780

1066724780

KOMATSU

6128711202

6128711202

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.5

2.45

2.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

14.3

Pump speed

r/min

1000

1000

1000

Each cylinder's injection qty

mm3/st.

250

245

255

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

17.1

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

349

346

352

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

8.6+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

28

25

31

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Test data Ex:

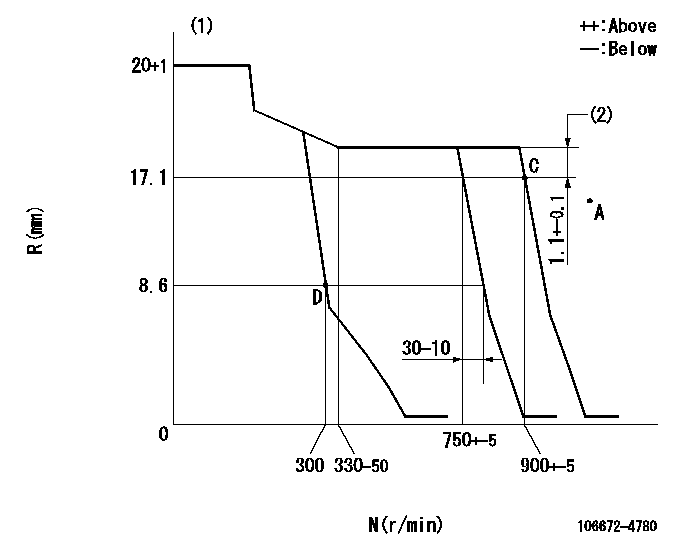

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Rack difference between N = N1 and N = N2

----------

K=14 N1=900r/min N2=750r/min

----------

----------

K=14 N1=900r/min N2=750r/min

----------

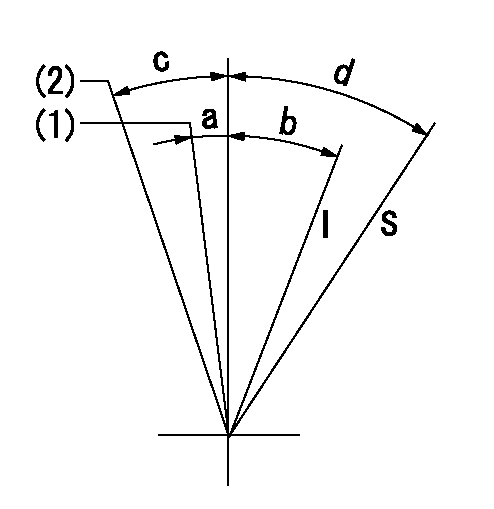

Speed control lever angle

I:Idle

S:Stop

(1)Set the pump speed at aa

(2)Set speed at bb (setting at shipping).

----------

aa=750r/min bb=900r/min

----------

a=6deg+-8deg b=19deg+-8deg c=15deg+-8deg d=32deg+-3deg

----------

aa=750r/min bb=900r/min

----------

a=6deg+-8deg b=19deg+-8deg c=15deg+-8deg d=32deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=(26.5deg) b=(53deg)

----------

----------

a=(26.5deg) b=(53deg)

Information:

Caterpillar: Confidential Yellow

PSP FOR FUEL INJECTION LINE FAILURES ON 627E, 627E PP AND 637E SCRAPERS - MAILED WORLDWIDE EXCEPT BRAZIL

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

U-35 A-20 AU-22 E-18 O-21 1252 PS4200 This Program can be administered either before or after a failure. In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS4200" as Part Number and "7755" as Group Number. Termination Date

February 28, 1989

Problem

The fuel injection lines on 627E, 627E PP and 637E Scrapers may crack as a result of excessive vibration. New fuel injection lines and supporting brackets can be installed.

Affected Product

Model Identification Number 627E 6EBl - 513 627E PP 6GB513 - 177, 579-582, 584, 585, 587, 588, 590-603 637E 1FB1 - 338, 341-348, 350-352 1JB1 - 548, 550, 553, 555, 556, 558-561, 563

Parts Needed

1 - 7C9564 Line As. 1 - 7C9565 Line As. 1 - 7C9566 Line As. 11 - 1W9168 Clamp 8 - 5P4939 Screw As. 11 - lW9169 Clamp 1 - 9Y1586 Bracket As. 1 - 9Y1653 Bracket As. 3 - 9N3388 Screw 1 - 9Y2681 Bar (as needed) The 9Y2681 Bar is only needed if the engine is not equipped with heat shields.

Action Required

Install the new parts as shown in the attached illustration. It is important that the 1W9168 and 1W9169 Clamps be installed at the locations shown in the illustration.

Service Claim Allowances

Product Caterpillar Dealer Suggested Customer Suggested smu/age Parts Labor Hrs. Parts Labor Hrs. Parts Labor Hrs. whichever (D/N) (Cost) (C/L) (Sell) comes first 0-2500

PSP FOR FUEL INJECTION LINE FAILURES ON 627E, 627E PP AND 637E SCRAPERS - MAILED WORLDWIDE EXCEPT BRAZIL

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

U-35 A-20 AU-22 E-18 O-21 1252 PS4200 This Program can be administered either before or after a failure. In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS4200" as Part Number and "7755" as Group Number. Termination Date

February 28, 1989

Problem

The fuel injection lines on 627E, 627E PP and 637E Scrapers may crack as a result of excessive vibration. New fuel injection lines and supporting brackets can be installed.

Affected Product

Model Identification Number 627E 6EBl - 513 627E PP 6GB513 - 177, 579-582, 584, 585, 587, 588, 590-603 637E 1FB1 - 338, 341-348, 350-352 1JB1 - 548, 550, 553, 555, 556, 558-561, 563

Parts Needed

1 - 7C9564 Line As. 1 - 7C9565 Line As. 1 - 7C9566 Line As. 11 - 1W9168 Clamp 8 - 5P4939 Screw As. 11 - lW9169 Clamp 1 - 9Y1586 Bracket As. 1 - 9Y1653 Bracket As. 3 - 9N3388 Screw 1 - 9Y2681 Bar (as needed) The 9Y2681 Bar is only needed if the engine is not equipped with heat shields.

Action Required

Install the new parts as shown in the attached illustration. It is important that the 1W9168 and 1W9169 Clamps be installed at the locations shown in the illustration.

Service Claim Allowances

Product Caterpillar Dealer Suggested Customer Suggested smu/age Parts Labor Hrs. Parts Labor Hrs. Parts Labor Hrs. whichever (D/N) (Cost) (C/L) (Sell) comes first 0-2500