Information injection-pump assembly

ZEXEL

106672-4710

1066724710

43547020B

Rating:

Cross reference number

ZEXEL

106672-4710

1066724710

43547020B

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.05

3

3.1

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

12.5

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

200

195

205

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

12.5

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

196

181

211

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

-

Rack position

6.2+-0.5

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

20

17

23

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_04

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

200

195

205

Fixing the lever

*

Rack limit

*

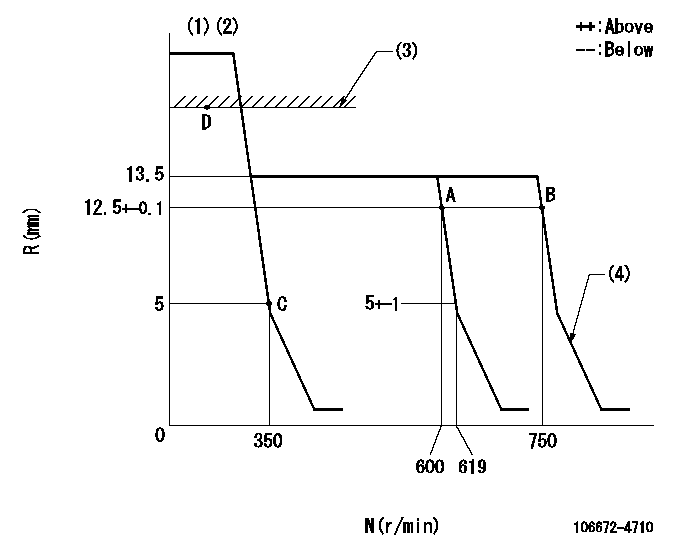

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Idle sub spring setting: L1.

----------

K=14 L1=4.5-0.5mm

----------

----------

K=14 L1=4.5-0.5mm

----------

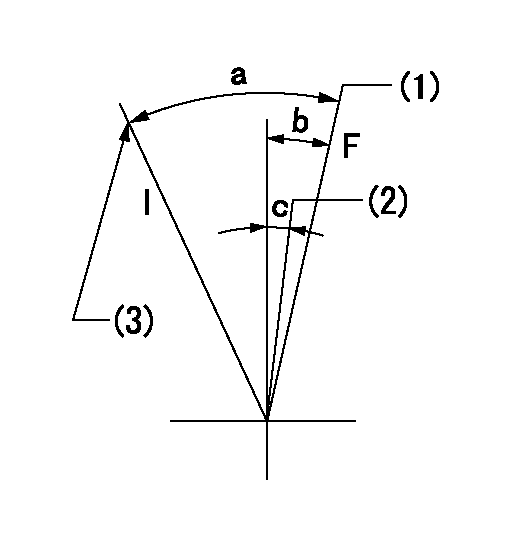

Speed control lever angle

F:Full speed

I:Idle

(1)Speed set at aa (setting at shipping)

(2)Set the pump speed at bb.

(3)Stopper bolt setting

----------

aa=750r/min bb=600r/min

----------

a=35deg+-5deg b=27deg+-5deg c=13deg+-5deg

----------

aa=750r/min bb=600r/min

----------

a=35deg+-5deg b=27deg+-5deg c=13deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Information:

Lubrication System

OIL LUBRICATION SCHEMATICThe lubrication system is the pressure type. The oil pump draws oil from the sump through a suction pipe and strainer to the pump. The oil pump is driven by the auxiliary drive group which is driven by the timing gears.Pressure oil flows to the oil cooler. The oil cooler is cooled by water from the cooling system. Coolers on T6.3544 Engines have a bypass valve that allows the oil to go around the cooler in case of a restriction or if the oil is too cold and thick. From the cooler, oil passes through the relief valve. On T6.3544 Engines, the relief valve is two stage. At 205 to 225 kPa (30 to 37 psi), oil is fed by a pipe to the piston cooling jet gallery which is a drilled passage the length of the crankcase, above the camshaft chamber. The piston cooling jets are bolted into the gallery and point into the bottom of each cylinder. Oil is sprayed onto the underneath side of each piston which takes heat from the combustion area. The oil then drains back to sump.At 345 to 415 kPa (50 to 60 psi), oil passes through a single oil filter on 6.3544 Engines or two filters on T6.3544 Engines. Oil then flows to the main oil gallery which is a drilled passage the length of the crankcase. Oil also flows from the filters to the turbocharger bearings on T6.3544 Engines. Passages in the crankcase webs feed oil from the main oil gallery to the main bearings. Passages in the crankshaft carry oil to the big end bearings. Through passages in No. 1, 3, 5 and 7 crankcase webs, oil passes from the main bearings to lubricate the camshaft bearings.The No. 2 camshaft bearing supplies a controlled amount of oil to the rocker shaft assembly, which then flows through a small bleed hole in each rocker lever to lubricate the valves and springs.Pistons, cylinder liners, connecting rod small end bushings, cam lobes and valve lifters are splash and oil mist lubricated.Oil flows from the main oil gallery to the two idler gear hubs. The oil passes through the hubs to radial passages in the idler gears to lubricate the teeth of the timing gears.The auxiliary drive group shaft bearings are lubricated by a passage from the main oil gallery to the front auxiliary drive shaft bearing. Oil then passes around a groove in the bearing journal and through another passage along the outer side of the auxiliary drive housing to the rear auxiliary drive shaft bearing. The upper fuel pump bearing is also lubricated from this passage. Also connected to this outer housing passage is a spray tube which directs oil on to the auxiliary drive shaft (worn gear) and gear assembly (worm wheel).Air Inlet And Exhaust System

6.3544 Engines

AIR INLET AND EXHAUST SYSTEM COMPONENTS

1. Exhaust manifold. 2. Inlet manifold. 3. Engine cylinderThe air inlet and exhaust system components on naturally aspirated engines are: the air cleaner, inlet manifold,

OIL LUBRICATION SCHEMATICThe lubrication system is the pressure type. The oil pump draws oil from the sump through a suction pipe and strainer to the pump. The oil pump is driven by the auxiliary drive group which is driven by the timing gears.Pressure oil flows to the oil cooler. The oil cooler is cooled by water from the cooling system. Coolers on T6.3544 Engines have a bypass valve that allows the oil to go around the cooler in case of a restriction or if the oil is too cold and thick. From the cooler, oil passes through the relief valve. On T6.3544 Engines, the relief valve is two stage. At 205 to 225 kPa (30 to 37 psi), oil is fed by a pipe to the piston cooling jet gallery which is a drilled passage the length of the crankcase, above the camshaft chamber. The piston cooling jets are bolted into the gallery and point into the bottom of each cylinder. Oil is sprayed onto the underneath side of each piston which takes heat from the combustion area. The oil then drains back to sump.At 345 to 415 kPa (50 to 60 psi), oil passes through a single oil filter on 6.3544 Engines or two filters on T6.3544 Engines. Oil then flows to the main oil gallery which is a drilled passage the length of the crankcase. Oil also flows from the filters to the turbocharger bearings on T6.3544 Engines. Passages in the crankcase webs feed oil from the main oil gallery to the main bearings. Passages in the crankshaft carry oil to the big end bearings. Through passages in No. 1, 3, 5 and 7 crankcase webs, oil passes from the main bearings to lubricate the camshaft bearings.The No. 2 camshaft bearing supplies a controlled amount of oil to the rocker shaft assembly, which then flows through a small bleed hole in each rocker lever to lubricate the valves and springs.Pistons, cylinder liners, connecting rod small end bushings, cam lobes and valve lifters are splash and oil mist lubricated.Oil flows from the main oil gallery to the two idler gear hubs. The oil passes through the hubs to radial passages in the idler gears to lubricate the teeth of the timing gears.The auxiliary drive group shaft bearings are lubricated by a passage from the main oil gallery to the front auxiliary drive shaft bearing. Oil then passes around a groove in the bearing journal and through another passage along the outer side of the auxiliary drive housing to the rear auxiliary drive shaft bearing. The upper fuel pump bearing is also lubricated from this passage. Also connected to this outer housing passage is a spray tube which directs oil on to the auxiliary drive shaft (worn gear) and gear assembly (worm wheel).Air Inlet And Exhaust System

6.3544 Engines

AIR INLET AND EXHAUST SYSTEM COMPONENTS

1. Exhaust manifold. 2. Inlet manifold. 3. Engine cylinderThe air inlet and exhaust system components on naturally aspirated engines are: the air cleaner, inlet manifold,