Information injection-pump assembly

BOSCH

9 400 618 263

9400618263

ZEXEL

106871-8272

1068718272

HINO

220203193A

220203193a

Rating:

Service parts 106871-8272 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

236002071A

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Include in #1:

106871-8272

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 618 263

9400618263

ZEXEL

106871-8272

1068718272

HINO

220203193A

220203193a

Zexel num

Bosch num

Firm num

Name

106871-8272

9 400 618 263

220203193A HINO

INJECTION-PUMP ASSEMBLY

EF750-TI * K 14CD INJECTION PUMP ASSY PE8P PE

EF750-TI * K 14CD INJECTION PUMP ASSY PE8P PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-3120

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-6-2-

7-5-4-3

Pre-stroke

mm

4.5

4.44

4.5

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-8 deg. 45 44.75 45.25

Cal 1-8 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-6 deg. 90 89.75 90.25

Cal 1-6 deg. 90 89.75 90.25

Difference between angles 3

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-7 deg. 180 179.75 180.25

Cal 1-7 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-4 deg. 270 269.75 270.25

Cal 1-4 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-3 deg. 315 314.75 315.25

Cal 1-3 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

10.4

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

162.4

160.4

164.4

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.2+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

13

10

16

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

150

150

170

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1050++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 1050.

Do not advance until starting N = 1050.

Timer adjustment_02

Pump speed

r/min

1050

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

0.5

0.5

0.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

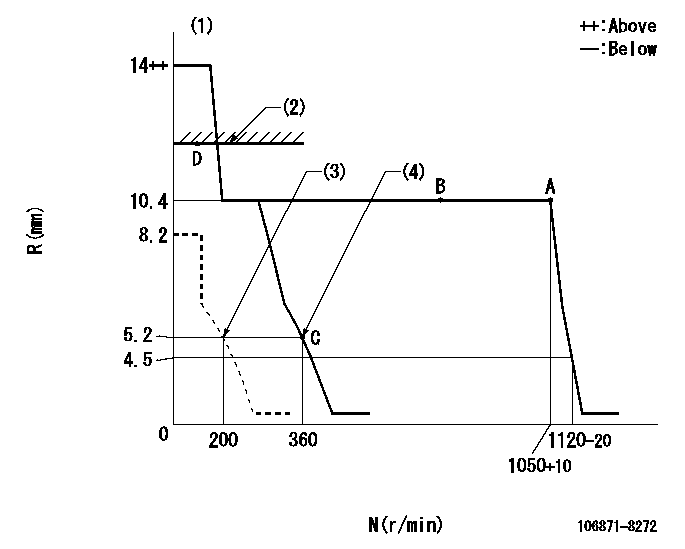

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Set idle sub-spring

(4)Main spring setting

----------

K=4

----------

----------

K=4

----------

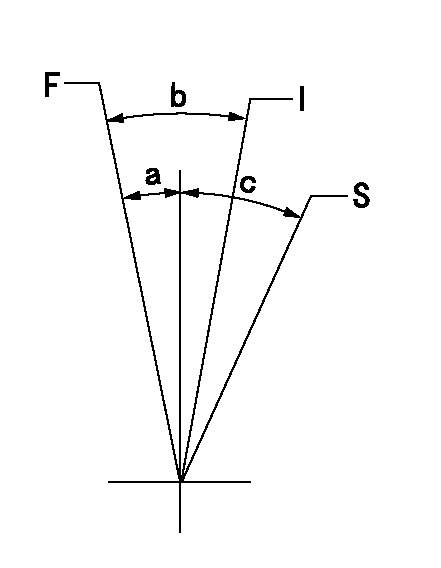

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=2deg+-5deg b=25deg+-5deg c=(35deg)

----------

----------

a=2deg+-5deg b=25deg+-5deg c=(35deg)

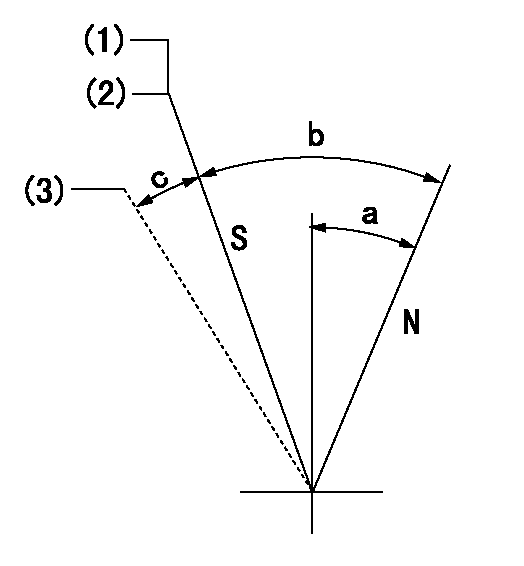

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At delivery

(2)Contacts inner stopper. Rack position aa or less, speed = bb

(3)Contacts outer stopper.

----------

aa=4.7mm bb=0r/min

----------

a=26.5deg+-5deg b=53deg+-5deg c=(11deg)

----------

aa=4.7mm bb=0r/min

----------

a=26.5deg+-5deg b=53deg+-5deg c=(11deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

TIMING PIN HOLE PLUG (Typical Example)

1. Plug.2. Rotate the crankshaft CLOCKWISE (as viewed from front of engine) until the timing pin drops into the timing slot in the fuel injection pump camshaft.3. Disconnect wire (2) from fuel shut off solenoid.4. Remove the tachometer drive adapter housing (3).

WIRE AND HOUSING (Typical Example)

2. Wire. 3. Tachometer drive adapter housing.5. Use ratchet (4) and socket (5) to remove the tachometer drive adapter shaft.

REMOVING SHAFT

4. 8H8572 Ratchet. 5. 9S5031 Deep Well Socket.6. Using puller group (6), thread the 9S8528 Bolt Assembly into the camshaft. Do not force the bolt assembly. It should thread easily. Install the 9S8527 Bolt by threading it into the gear carrier or adapter. Then tighten the 9S8527 Bolt with a wrench until the gear carrier or adapter "pops" loose. Remove the 9S8520 Puller Group.

LOOSENING CAMSHAFT DRIVE GEAR

6. 9S8520 Puller Group.7. Remove the plug from the timing hole (8) in the front cover and insert bolt (7). The cover retaining bolt from hole (9) may be used.8. Rotate crankshaft CLOCKWISE (as viewed from front of engine) until bolt (7) threads into the timing gear and is centered in timing hole (8). With timing pin in slot in fuel pump camshaft and the bolt (7) through the front cover and threaded into the timing gear, the fuel injection pump camshaft is timed to the engine.

INSTALLING BOLT

7. 1D4539 Bolt [5/16 in. - 18 NC, 2.5 in. (63.5 mm) long]. 8. Timing hole. 9. Hole.9. Remove the fuel injection pump housing retaining bolts (10).

RETAINING BOLTS (Typical Example)

10. Retaining bolts (three).

REMOVING HOUSING (Typical Example)10. Attach a hoist and remove the fuel injection pump housing and governor as a unit, the weight is approx. 55 lbs. (23 kg).Install Fuel Injection Pump Housing and Governor

1. Attach a hoist and install the fuel injection pump housing and governor as a unit. Install the fuel injection pump housing retaining bolts.2. Install the tachometer drive adapter shaft and tighten shaft retaining nut to 32 2 lb. ft. (4.4 0.3 mkg).3. To check timing remove the timing pin and the bolt. Rotate the crankshaft two revolutions CLOCKWISE (as viewed from front of engine) and install the timing pin and bolt back in place. If the timing pin or bolt can not be installed, the fuel injection pump camshaft must be retimed.4. Remove the bolt (7) from the timing gear and install in hole (9). Install the plug into timing hole (8).5. Remove the timing pin from the timing slot in the fuel injection pump camshaft and install the plug in the timing hole.6. Install the tachometer drive adapter housing. Connect the wire to the fuel shut off solenoid.

Have questions with 106871-8272?

Group cross 106871-8272 ZEXEL

Hino

106871-8272

9 400 618 263

220203193A

INJECTION-PUMP ASSEMBLY

EF750-TI

EF750-TI