Information injection-pump assembly

BOSCH

9 460 611 900

9460611900

ZEXEL

104745-8070

1047458070

MITSUBISHI

MD331231

md331231

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104745-8070 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104645-8070 |

| 3. | NUMBER PLATE | 146959-4600 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1311 |

| 8. | Nozzle and Holder | MD196607 |

| 9. | Open Pre:MPa(Kqf/cm2) | 14.7{150} |

| 10. | NOZZLE-HOLDER | 105078-0181 |

| 11. | NOZZLE | 105007-1300 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0220 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0320 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0300 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-3520 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-2120 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-6520 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2800 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2900 | COMPRESSION SPRING |

| 34C. | [1] | 146312-2700 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM D17&5.2T2.8 |

| 48/1. | [1] | 146690-6600 | SHIM D17&5.2T2.9 |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM D17&5.2T3.4 |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM D17&5.2T0.6 |

| 48/1. | [1] | 146690-7400 | SHIM D17&5.2T0.7 |

| 48/1. | [1] | 146690-7500 | SHIM D17&5.2T1.9 |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146401-0221 | HYDRAULIC HEAD |

| 50. | [1] | 146401-0221 | HYDRAULIC HEAD |

| 50. | [1] | 146401-0221 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-0320 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0320 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 67. | [1] | 146820-2320 | GOVERNOR COVER |

| 67/1. | [1] | 146508-8221 | GOVERNOR COVER |

| 67/2. | [1] | 146515-0320 | CONTROL SHAFT |

| 67/3. | [1] | 146600-0100 | O-RING |

| 67/4. | [1] | 139310-0200 | PLAIN WASHER |

| 67/13. | [1] | 146621-1700 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 72. | [1] | 146830-7620 | CONTROL LEVER |

| 72B. | [1] | 146830-7720 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 95. | [1] | 146551-6120 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146975-7900 | SLIDING SLEEVE |

| 116. | [1] | 146576-0000 | SEALING CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 120. | [1] | 146579-5320 | RETAINING PIN |

| 122. | [1] | 146580-2300 | GOVERNOR SPRING |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0020 | OVER FLOW VALVE |

| 137. | [2] | 139512-0500 | GASKET |

| 138. | [1] | 146605-8620 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 029470-4030 | WOODRUFF KEY |

| 217. | [1] | 146542-5300 | SLOTTED WASHER |

| 218. | [1] | 146592-2500 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-2600 | COILED SPRING |

| 224. | [1] | 139006-4700 | BLEEDER SCREW |

| 229. | [1] | 146928-1220 | BRACKET |

| 230. | [1] | 146629-2120 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 232. | [1] | 146931-3200 | BRACKET |

| 233. | [1] | 146658-9020 | WIRE |

| 234. | [1] | 139006-4800 | BLEEDER SCREW |

| 235. | [1] | 146659-0600 | CLAMPING BAND |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [2] | 139512-0500 | GASKET |

| 246. | [1] | 146125-0300 | EYE BOLT |

| 247. | [1] | 146666-0120 | INLET UNION |

| 251. | [1] | 146125-0101 | FILTER |

| 252. | [1] | 146125-0200 | COILED SPRING |

| 253. | [1] | 139006-4500 | BLEEDER SCREW |

| 275. | [1] | 146612-4800 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 280. | [1] | 146361-7020 | START ADVANCE ASSY |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 010206-1240 | HEX-SOCKET-HEAD CAP SCREW M6P1L12 |

| 286. | [1] | 020106-3040 | BLEEDER SCREW |

| 287. | [1] | 014010-6140 | PLAIN WASHER D13&6.5T1 |

| 800S. | [1] | 146018-5120 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 903. | [1] | 146620-0120 | CAPSULE |

| 903/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 906. | [1] | 146959-4600 | NAMEPLATE |

| 910S. | [1] | 146600-4020 | PARTS SET |

| 910S. | [1] | 146600-4020 | PARTS SET |

| 912S. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 913S. | [1] | 146422-0000 | BLEEDER SCREW |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 915S. | [1] | 146658-9020 | WIRE |

| 916S. | [1] | 025804-1610 | WOODRUFF KEY |

Include in #2:

104745-8070

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 611 900

9460611900

ZEXEL

104745-8070

1047458070

MITSUBISHI

MD331231

md331231

Zexel num

Bosch num

Firm num

Name

104745-8070

9 460 611 900

MD331231 MITSUBISHI

INJECTION-PUMP ASSEMBLY

4D56 K 11CJ INJECTION PUMP ASSY VE4 VE

4D56 K 11CJ INJECTION PUMP ASSY VE4 VE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

44.4

43.9

44.9

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

45.3

43.3

47.3

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

44.4

43.4

45.4

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

42.3

40.3

44.3

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

43.7

41.6

45.8

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

19.5

16.5

22.5

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2900

2900

2900

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

19.5

14.5

24.5

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

12.5

11

14

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

12.5

10.5

14.5

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

3

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

70

60

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

70

60

80

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

420

290

550

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

471

442

500

Pressure

kgf/cm2

4.8

4.5

5.1

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

600

600

600

Pressure

kPa

314

275

353

Pressure

kgf/cm2

3.2

2.8

3.6

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Pressure

kPa

471

432

510

Pressure

kgf/cm2

4.8

4.4

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2100

2100

2100

Pressure

kPa

667

628

706

Pressure

kgf/cm2

6.8

6.4

7.2

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

4.7

4.5

4.9

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

500

500

500

Timer stroke

mm

1.5

0.9

2.1

Oil temperature

degC

48

46

50

_03

Pump speed

r/min

750

750

750

Timer stroke

mm

2.6

2

3.2

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

4.7

4.3

5.1

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1750

1750

1750

Timer stroke

mm

7

6.4

7.6

Oil temperature

degC

50

48

52

_06

Pump speed

r/min

2100

2100

2100

Timer stroke

mm

8.6

8

9.2

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

31.6

31.1

32.1

Timer stroke TA

mm

4.2

4.2

4.2

Timer stroke variation dT

mm

0.5

0.3

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

31.6

30.6

32.6

Timer stroke variation dT

mm

0.5

0.1

0.9

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

21.5

20.5

22.5

Timer stroke variation dT

mm

1.2

0.6

1.8

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.2

1.1

1.3

Control lever angle alpha

deg.

55

51

59

Control lever angle beta

deg.

41

36

46

Test data Ex:

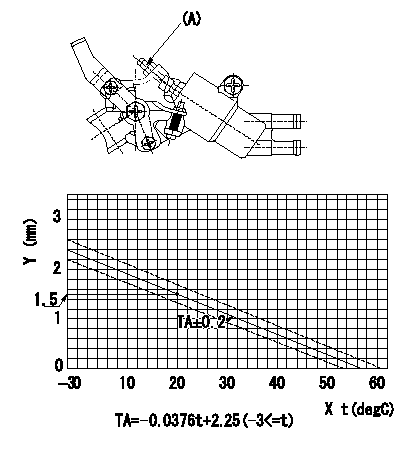

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the advance angle of the timer

(1)Determine the timer advance angle using the graph.

(2)(1) Adjust with the screw (A) so that the timer advance angle determined in the item (1) is obtained.

X = temperature t

Y = timer stroke

----------

----------

----------

----------

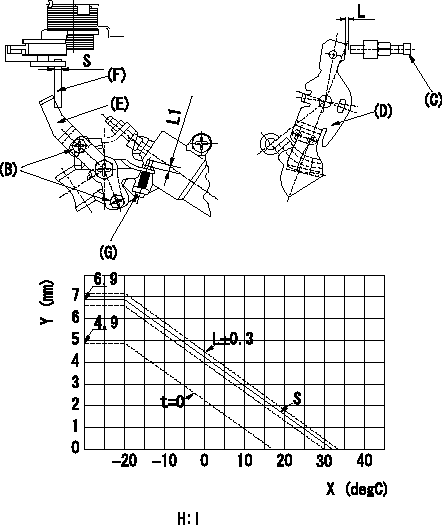

0000001901 W-FICD LEVER ADJUSTMENT

2. Adjustment of the W-FICD

(1)Insert a block gauge L2 determined from the graph below between the control lever (D) and the idling stopper bolt (C).

(2)Insert a shim S between the W-FICD lever (E) and the control lever (F). Adjust the W-FICD lever (E) so that it contacts the control lever (F) and fix it using bolt (B).

TT

Note:

a) The temperature of wax at the time of adjustment must not exceed a.

b) After completion of the adjustment, confirm that allowance for adjustment of the screw (G) is at least L1.

X:Temperature X (deg C)

Y:Control lever: dimension L (mm) (control lever position)

H:Graph, L - X graph

----------

L2=L+-0.05mm S=3+-0.05mm T=3.4~4.9N-m(0.35~0.5kgf-m) a=30degC L1=3mm

----------

L1=3++mm S=(3mm) H:L=-0.132X+4.29(-20<=X)(S=3+-0.05)

----------

L2=L+-0.05mm S=3+-0.05mm T=3.4~4.9N-m(0.35~0.5kgf-m) a=30degC L1=3mm

----------

L1=3++mm S=(3mm) H:L=-0.132X+4.29(-20<=X)(S=3+-0.05)

Information:

This Program must be administered as soon as possible. When reporting the repair, use "PI3325" as the Part Number, "7751" as the Group Number, "56" as the Warranty Claim Description Code and "T" as the SIMS Description Code. Exception: If the repair is done after failure, use "PI3325" as the Part Number, "7751" as the Group Number, "96" as the Warranty Claim Description Code, and "Z" as the SIMS Description Code.

Completion Date

February 29, 2000Termination Date

February 29, 2000Problem

Upgrade software needs to be installed on certain 3606, 3608, 3612, and 3616 diesel engines with the Marine Monitoring System (MMS) to become Y2K compatible.

Affected Product

Model & Identification Number

3606 (8RB29, 8RB656-661, 8RB669, 8RB672-673, 8RB680-688, 8RB691-00692, 8RB695-702, 8RB711-00713, 8RB715, 8RB717-718, 8RB721-723)

3608 (6MC535-536, 6MC550, 6MC561-562, 6MC582-586)

3612 (9RC230, 9RC242, 9RC247-253, 9RC256-257, 9RC259-260)

3616 (1PD289-293, 1PD295, 1PD306, 1PD308, 1PD313-336)

Parts Needed

- Dealers will need to obtain the Upgrade Files for this program.- 1 Blank formatted 1.44 MB floppy disk for Winfile Upgrade- 6 Blank formatted 1.44 MB floppy disks for InTouch 5.6B UpgradeAction Required

See the attached procedure.

Owner Notification

U.S. and Canadian owners will receive the attached Owner Notification.

Service Claim Allowances

This is a 1-hour job.

U.S. and Canadian Dealers Only - Eligible dealers may enter a Type 2 SIMS Report.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

Attach.(1-Owner Notification)(1-Rework Procedure)Copy Of Owner Notification For U.S. And Canadian Owners

Rework Procedure

Windows 3.11 Winfile Upgrade

This upgrade is necessary for Windows 3.11 to correctly date stamp files after the year 2000, The first three steps in the following procedure will be done in the office or shop.

1. Obtain the file. The file can be obtained from the Caterpillar Mailbox, SISWEB, or from the SIS disks that are released monthly. The file part number is 174-8693.2. Unzip the file. The 174-8693.exe file is a self-executing zip file. To Unzip, place the file in a known location on the hard drive. Run the file. At the dialog box type in 'A:\' where it asks for the folder to place unzipped files. Install a blank formatted disk into the A: drive. Select UNZIP or press "ENTER". This will unzip the files to the floppy drive. If your floppy drive is not 'A:' substitute your floppy drive letter for A in the above instuctions.)

3. Label the disk. This disk should be labeled "Winfile.exe Y2K Upgrade". This disk or a copy of this disk can be used to do multiple upgrades. It is not necessary to repeat steps 1-3 for each upgrade.4. Perform the upgrade. The upgrade should be done from the DOS prompt. Attach a keyboard to the MMS computer. With the MMS program running press "ALT"and "F4" at the same time. This will exit the MMS program. Press "ALT"and "F4" at the same time again and you will get a dialog box that asks you to confirm you want to end your Windows session. Press "ENTER" to confirm. Install the floppy labeled "Winfile.exe Y2K Upgrade" into the floppy drive on the MMS

Completion Date

February 29, 2000Termination Date

February 29, 2000Problem

Upgrade software needs to be installed on certain 3606, 3608, 3612, and 3616 diesel engines with the Marine Monitoring System (MMS) to become Y2K compatible.

Affected Product

Model & Identification Number

3606 (8RB29, 8RB656-661, 8RB669, 8RB672-673, 8RB680-688, 8RB691-00692, 8RB695-702, 8RB711-00713, 8RB715, 8RB717-718, 8RB721-723)

3608 (6MC535-536, 6MC550, 6MC561-562, 6MC582-586)

3612 (9RC230, 9RC242, 9RC247-253, 9RC256-257, 9RC259-260)

3616 (1PD289-293, 1PD295, 1PD306, 1PD308, 1PD313-336)

Parts Needed

- Dealers will need to obtain the Upgrade Files for this program.- 1 Blank formatted 1.44 MB floppy disk for Winfile Upgrade- 6 Blank formatted 1.44 MB floppy disks for InTouch 5.6B UpgradeAction Required

See the attached procedure.

Owner Notification

U.S. and Canadian owners will receive the attached Owner Notification.

Service Claim Allowances

This is a 1-hour job.

U.S. and Canadian Dealers Only - Eligible dealers may enter a Type 2 SIMS Report.

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

Attach.(1-Owner Notification)(1-Rework Procedure)Copy Of Owner Notification For U.S. And Canadian Owners

Rework Procedure

Windows 3.11 Winfile Upgrade

This upgrade is necessary for Windows 3.11 to correctly date stamp files after the year 2000, The first three steps in the following procedure will be done in the office or shop.

1. Obtain the file. The file can be obtained from the Caterpillar Mailbox, SISWEB, or from the SIS disks that are released monthly. The file part number is 174-8693.2. Unzip the file. The 174-8693.exe file is a self-executing zip file. To Unzip, place the file in a known location on the hard drive. Run the file. At the dialog box type in 'A:\' where it asks for the folder to place unzipped files. Install a blank formatted disk into the A: drive. Select UNZIP or press "ENTER". This will unzip the files to the floppy drive. If your floppy drive is not 'A:' substitute your floppy drive letter for A in the above instuctions.)

3. Label the disk. This disk should be labeled "Winfile.exe Y2K Upgrade". This disk or a copy of this disk can be used to do multiple upgrades. It is not necessary to repeat steps 1-3 for each upgrade.4. Perform the upgrade. The upgrade should be done from the DOS prompt. Attach a keyboard to the MMS computer. With the MMS program running press "ALT"and "F4" at the same time. This will exit the MMS program. Press "ALT"and "F4" at the same time again and you will get a dialog box that asks you to confirm you want to end your Windows session. Press "ENTER" to confirm. Install the floppy labeled "Winfile.exe Y2K Upgrade" into the floppy drive on the MMS

Have questions with 104745-8070?

Group cross 104745-8070 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

104745-8070

9 460 611 900

MD331231

INJECTION-PUMP ASSEMBLY

4D56

4D56