Information injection-pump assembly

BOSCH

9 460 610 914

9460610914

ZEXEL

104745-3620

1047453620

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104745-3620 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104645-3620 |

| 3. | NUMBER PLATE | 146957-0500 |

| 4. | _ | 479771-0520 |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1311 |

| 8. | Nozzle and Holder | MD196607 |

| 9. | Open Pre:MPa(Kqf/cm2) | 14.7{150} |

| 10. | NOZZLE-HOLDER | 105078-0181 |

| 11. | NOZZLE | 105007-1300 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0220 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0320 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0300 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-3520 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-0020 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-6320 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2900 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2800 | COMPRESSION SPRING |

| 34C. | [1] | 146312-3200 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-1600 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 42. | [1] | 146602-8500 | PLAIN WASHER |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0020 | GUIDE PIN |

| 50. | [1] | 146401-3320 | HYDRAULIC HEAD |

| 50. | [1] | 146401-3320 | HYDRAULIC HEAD |

| 50. | [1] | 146401-3320 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-2020 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0320 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 67. | [1] | 146704-1120 | COMPENSATOR,MANIFOLD-PRES |

| 67/1. | [1] | 146805-7220 | GOVERNOR COVER |

| 67/2. | [1] | 146515-0320 | CONTROL SHAFT |

| 67/3. | [1] | 146600-0100 | O-RING |

| 67/4. | [1] | 139310-0200 | PLAIN WASHER |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/16. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/23. | [1] | 146925-7520 | BRACKET |

| 67/24. | [2] | 010206-2240 | HEX-SOCKET-HEAD CAP SCREW |

| 67/31. | [1] | 146710-0700 | BUSHING |

| 67/32. | [1] | 146711-0000 | PLATE |

| 67/33. | [1] | 139218-0400 | UNION NUT |

| 67/34. | [1] | 146712-0700 | BEARING PIN |

| 67/35. | [1] | 146621-0300 | UNION NUT |

| 67/36. | [1] | 146600-1400 | O-RING |

| 67/37. | [1] | 146710-0100 | BUSHING |

| 67/38. | [1] | 139506-0200 | GASKET D8.9&6.8T1.00 |

| 67/39. | [1] | 146620-0300 | CAPSULE |

| 67/40. | [1] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 67/41. | [1] | 146713-4300 | ADJUSTING PIN |

| 67/42. | [2] | 146714-0200 | PLATE |

| 67/43. | [1] | 146715-0300 | DIAPHRAGM |

| 67/44. | [1] | 139306-0100 | LOCKING WASHER |

| 67/45. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 67/46. | [1] | 146716-0000 | UNION NUT |

| 67/47. | [1] | 146717-2900 | COILED SPRING |

| 67/48/1. | [1] | 146720-3000 | SPACER BUSHING L3.7 |

| 67/48/1. | [1] | 146720-3100 | SPACER BUSHING L3.9 |

| 67/48/1. | [1] | 146720-3200 | SPACER BUSHING L4.1 |

| 67/48/1. | [1] | 146720-3300 | SPACER BUSHING L4.3 |

| 67/48/1. | [1] | 146720-3400 | SPACER BUSHING L4.5 |

| 67/48/1. | [1] | 146720-3500 | SPACER BUSHING L4.7 |

| 67/48/1. | [1] | 146720-3600 | SPACER BUSHING L4.9 |

| 67/48/1. | [1] | 146720-3700 | SPACER BUSHING L5.1 |

| 67/48/1. | [1] | 146720-3800 | SPACER BUSHING L5.3 |

| 67/48/1. | [1] | 146720-3900 | SPACER BUSHING L5.5 |

| 67/48/1. | [1] | 146720-4000 | SPACER BUSHING L5.7 |

| 67/48/1. | [1] | 146720-4100 | SPACER BUSHING L5.9 |

| 67/48/1. | [1] | 146720-4200 | SPACER BUSHING L6.1 |

| 67/48/1. | [1] | 146720-4300 | SPACER BUSHING L6.3 |

| 67/48/1. | [1] | 146720-4400 | SPACER BUSHING L6.5 |

| 67/48/1. | [1] | 146720-8900 | SPACER BUSHING L6.7 |

| 67/48/1. | [1] | 146720-9000 | SPACER BUSHING L6.9 |

| 67/48/1. | [1] | 146720-9100 | SPACER BUSHING L7.1 |

| 67/48/1. | [1] | 146720-9200 | SPACER BUSHING L7.3 |

| 67/48/1. | [1] | 146720-9300 | SPACER BUSHING L7.5 |

| 67/48/1. | [1] | 146720-9400 | SPACER BUSHING L7.7 |

| 67/48/1. | [1] | 146720-9500 | SPACER BUSHING L7.9 |

| 67/48/1. | [1] | 146720-9600 | SPACER BUSHING L8.1 |

| 67/48/1. | [1] | 146720-9700 | SPACER BUSHING L8.3 |

| 67/48/1. | [1] | 146720-9800 | SPACER BUSHING L8.5 |

| 67/48/1. | [1] | 146720-9900 | SPACER BUSHING L3.6 |

| 67/48/1. | [1] | 146725-0000 | SPACER BUSHING L3.8 |

| 67/48/1. | [1] | 146725-0100 | SPACER BUSHING L4.0 |

| 67/48/1. | [1] | 146725-0200 | SPACER BUSHING L4.2 |

| 67/48/1. | [1] | 146725-0300 | SPACER BUSHING L4.4 |

| 67/48/1. | [1] | 146725-0400 | SPACER BUSHING L4.6 |

| 67/48/1. | [1] | 146725-0500 | SPACER BUSHING L4.8 |

| 67/48/1. | [1] | 146725-0600 | SPACER BUSHING L5.0 |

| 67/48/1. | [1] | 146725-0700 | SPACER BUSHING L5.2 |

| 67/48/1. | [1] | 146725-0800 | SPACER BUSHING L5.4 |

| 67/48/1. | [1] | 146725-0900 | SPACER BUSHING L5.6 |

| 67/48/1. | [1] | 146725-1000 | SPACER BUSHING L5.8 |

| 67/48/1. | [1] | 146725-1100 | SPACER BUSHING L6.0 |

| 67/48/1. | [1] | 146725-1200 | SPACER BUSHING L6.2 |

| 67/48/1. | [1] | 146725-1300 | SPACER BUSHING L6.4 |

| 67/48/1. | [1] | 146725-1400 | SPACER BUSHING L6.6 |

| 67/48/1. | [1] | 146725-1500 | SPACER BUSHING L6.8 |

| 67/48/1. | [1] | 146725-1600 | SPACER BUSHING L7.0 |

| 67/48/1. | [1] | 146725-1700 | SPACER BUSHING L7.2 |

| 67/48/1. | [1] | 146725-1800 | SPACER BUSHING L7.4 |

| 67/48/1. | [1] | 146725-1900 | SPACER BUSHING L7.6 |

| 67/48/1. | [1] | 146725-2000 | SPACER BUSHING L7.8 |

| 67/48/1. | [1] | 146725-2100 | SPACER BUSHING L8.0 |

| 67/48/1. | [1] | 146725-2200 | SPACER BUSHING L8.2 |

| 67/48/1. | [1] | 146725-2300 | SPACER BUSHING L8.4 |

| 67/48/1. | [1] | 146725-2400 | SPACER BUSHING L8.6 |

| 67/49. | [1] | 146721-3720 | COVER |

| 67/50. | [1] | 146722-0200 | FLAT-HEAD SCREW |

| 67/51. | [1] | 146600-0300 | O-RING |

| 67/53. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 67/54. | [2] | 139006-4700 | BLEEDER SCREW |

| 67/54. | [2] | 139006-4700 | BLEEDER SCREW |

| 67/55. | [2] | 139006-4600 | BLEEDER SCREW |

| 67/56. | [1] | 146723-0200 | CONTROL LEVER |

| 67/57. | [1] | 146712-0100 | BEARING PIN |

| 67/58. | [2] | 146620-0600 | CAPSULE |

| 67/59. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 67/60. | [1] | 146724-0300 | ELEMENT |

| 67/61. | [1] | 146724-0600 | CAPSULE |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/96. | [1] | 146659-7220 | CLAMPING BAND |

| 67/112. | [1] | 146926-5520 | BRACKET |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 72. | [1] | 146830-7120 | CONTROL LEVER |

| 72B. | [1] | 146830-7220 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 95. | [1] | 146550-1620 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146875-8300 | SLIDING SLEEVE |

| 116. | [1] | 146576-0000 | SEALING CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 120. | [1] | 146879-0220 | RETAINING PIN |

| 122. | [1] | 146580-2300 | GOVERNOR SPRING |

| 123. | [4] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0020 | OVER FLOW VALVE |

| 137. | [2] | 026512-1840 | GASKET D17.9&12.2T1.50 |

| 138. | [1] | 146665-4520 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 029470-4030 | WOODRUFF KEY |

| 217. | [1] | 146542-5300 | SLOTTED WASHER |

| 218. | [1] | 146592-2500 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-2600 | COILED SPRING |

| 224. | [1] | 139006-4700 | BLEEDER SCREW |

| 230. | [1] | 146931-3400 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 233. | [1] | 146658-9020 | WIRE |

| 234. | [1] | 139006-4800 | BLEEDER SCREW |

| 235. | [1] | 146659-0600 | CLAMPING BAND |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [3] | 026512-1840 | GASKET D17.9&12.2T1.50 |

| 246. | [1] | 139812-1900 | EYE BOLT |

| 247. | [1] | 146666-8520 | INLET UNION |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 251. | [1] | 146125-0101 | FILTER |

| 252. | [1] | 146125-0200 | COILED SPRING |

| 275. | [1] | 146612-4800 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 280. | [1] | 146361-2120 | START ADVANCE ASSY |

| 281. | [1] | 146600-0800 | O-RING |

| 283. | [1] | 146679-2821 | ADJUSTING DEVICE |

| 284. | [2] | 139005-0400 | BLEEDER SCREW |

| 800S. | [1] | 146018-4820 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 903. | [1] | 146672-2820 | PULSE GENERATOR |

| 903/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 906. | [1] | 146957-0500 | NAMEPLATE |

| 910S. | [1] | 146600-4220 | PARTS SET |

| 910S. | [1] | 146600-4220 | PARTS SET |

| 911S. | [1] | 146672-2820 | PULSE GENERATOR |

| 911S/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 912S. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 913S. | [1] | 146422-0000 | BLEEDER SCREW |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 915S. | [1] | 146658-9020 | WIRE |

| 916S. | [1] | 025804-1610 | WOODRUFF KEY |

Include in #2:

104745-3620

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 610 914

9460610914

ZEXEL

104745-3620

1047453620

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

52.6

52.1

53.1

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

44

42.7

45.3

Boost pressure

mmHg

330

320

340

Average injection quantity

mm3/st.

62.6

62.1

63.1

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

76.6

76.1

77.1

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

52.6

51.6

53.6

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

750

750

750

Boost pressure

kPa

44

42.7

45.3

Boost pressure

mmHg

330

320

340

Average injection quantity

mm3/st.

62.6

61.6

63.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

77

74.5

79.5

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

76.6

75.6

77.6

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_08

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

65

62.5

67.5

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2650

2650

2650

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

27.9

24.9

30.9

Difference in delivery

mm3/st.

8.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2950

2950

2950

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2650

2650

2650

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

27.9

22.9

32.9

Difference in delivery

mm3/st.

9

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

19.4

17.9

20.9

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

19.4

17.4

21.4

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

8

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

65

85

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

65

85

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Overflow quantity

cm3/min

420

290

550

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

549

520

578

Pressure

kgf/cm2

5.6

5.3

5.9

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

4.6

4.4

4.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

500

500

500

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

1.2

0.6

1.8

Oil temperature

degC

48

46

50

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

3.5

2.9

4.1

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

4.6

4.2

5

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

5.6

5

6.2

Oil temperature

degC

50

48

52

_06

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

7.8

7.2

8.4

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

56.9

56.4

57.4

Timer stroke TA

mm

3.9

3.7

4.1

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

56.9

55.9

57.9

Timer stroke TA

mm

3.9

3.5

4.3

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

43

42

44

Timer stroke TA

mm

2.5

1.9

3.1

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.2

1.1

1.3

Control lever angle alpha

deg.

61

57

65

Control lever angle beta

deg.

42

37

47

Test data Ex:

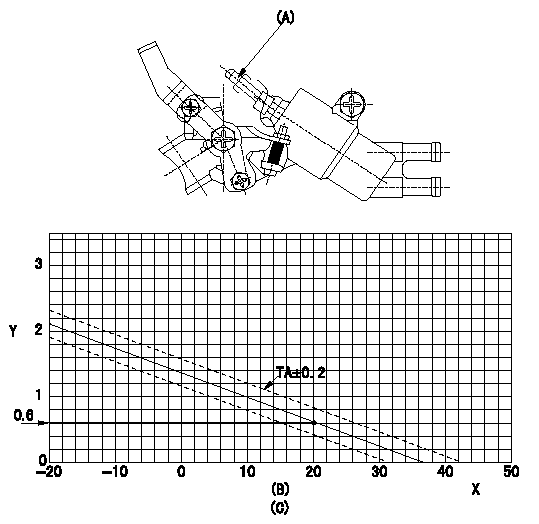

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the advance angle of the timer

(1)Determine the timer advance angle using the following graph.

(2)(1) Adjust with the screw (A) so that the timer advance angle determined in the item (1) is obtained.

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

(B): Timer stroke TA (mm):

----------

----------

(C)=TA=-0.0376t+1.38(-20<=t)

----------

----------

(C)=TA=-0.0376t+1.38(-20<=t)

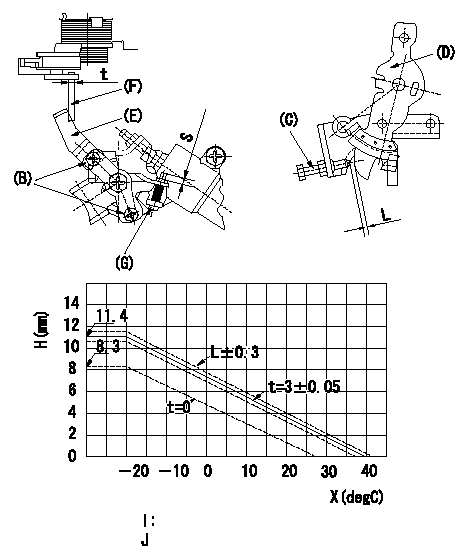

0000001901 W-FICD LEVER ADJUSTMENT

2. Adjustment of the W-FICD

(1)Insert a block gauge L1 determined from the graph below between the control lever (D) and the idling stopper bolt (C).

(2)Insert a shim t between the W-FICD lever (E) and the control lever (F). Adjust the W-FICD lever (E) so that it contacts the control lever (F) and fix it using bolt (B).

TT

Note:

a) The temperature of the wax at the time of adjustment must not exceed d.

b) After completing adjustment, confirm that adjustment allowance of the screw (G) is at least S.

H = control lever dimension L (control lever position)

X = temperature X

I = graph L - X

----------

L1=L+-0.05mm t=3+-0.05mm T=3.4~4.9N-m(0.35~0.5kgf-m) d=30degC S=3mm

----------

t=3mm S=Above 3mm J:L=-0.177X+7.80(-20<=X(degC))(t=3+-0.05)

----------

L1=L+-0.05mm t=3+-0.05mm T=3.4~4.9N-m(0.35~0.5kgf-m) d=30degC S=3mm

----------

t=3mm S=Above 3mm J:L=-0.177X+7.80(-20<=X(degC))(t=3+-0.05)

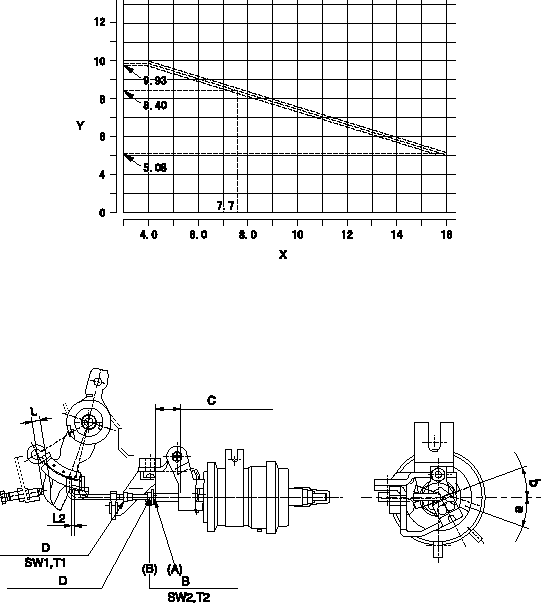

0000002001 V-FICD ADJUSTMENT

Adjustment of the two stage actuator (FICD).

B:Stroke adjusting nut

C:Actuator stroke

D:Rod position adjusting nut

X:Injection quantity (cm3/1,000st)

Y:Thickness of the shim L (mm)

1. Selecting the shim for adjusting the actuator.

(1)Measure the injection quantity at N by inserting the shim L1 between the control lever and the idling stopper bolt.

(2)Select the thickness (L) of the shim for adjusting the actuator using the following formula (Refer to the graph.).

L+-0.1 = -0.4045*Q + 11.549 mm (4.0 <= Q <=16.0 cm3/1,000 st)

2. Adjustment of the actuator

(1)Mount the actuator to the injection pump.

(2)Position the control lever at the idling position.

(3)Adjust with the nut (D) so that the space between the control lever and the rod becomes L2.

(4)Insert the shim (L) determined above between the control lever and the idling stopper bolt.

(5)Adjust the position of the screw (A) so that the actuator can make its full stroke (Reference value: L3 approx.) and fix with the nut (B).

(6)Allowable angle in adjusting the position of the rod: c

----------

N=900(r/min) L1=8.4(mm) L2=1+1(mm) L3=9.6(mm) c=+-20(deg)

----------

a=20deg b=20deg T1=1.4~2N-m(0.14~0.2kgf-m) T2=3.5~5N-m(0.35~0.5kgf-m) L2=1+1mm SW1=SW7 SW2=SW8

----------

N=900(r/min) L1=8.4(mm) L2=1+1(mm) L3=9.6(mm) c=+-20(deg)

----------

a=20deg b=20deg T1=1.4~2N-m(0.14~0.2kgf-m) T2=3.5~5N-m(0.35~0.5kgf-m) L2=1+1mm SW1=SW7 SW2=SW8

Information:

Do not use the same vacuum sampling pump for extracting oil samples that is used for extracting coolant samples.A small residue of either type sample may remain in the pump and may cause a false positive analysis for the sample being taken.Always use a separate pump for oil sampling and a separate pump for coolant sampling.Failure to do so may cause a false analysis which could lead to customer and dealer concerns.

New Systems, Refilled Systems, and Converted Systems

Perform an S O S coolant analysis (Level 2) at the following maintenance intervals.

Initial 500 service hours

Every Year or every 2000 hours, whichever comes firstPerform this analysis at the interval that occurs first for new systems, for refilled systems, or for converted systems that use Cat ELC (Extended Life Coolant) or use Cat DEAC (Diesel Engine Antifreeze/Coolant). This 500 hour check will also check for any residual cleaner that may have contaminated the system.Recommended Interval for S O S Services Coolant Sample

The following table contains the recommended sampling interval for all coolants that meet Cat EC-1 (Engine Coolant specification - 1). This is also the recommended sampling interval for all conventional heavy-duty coolant/antifreeze.The Level 2 Coolant Analysis should be performed if a problem is suspected or identified.

Table 1

Recommended Interval

Type of Coolant Level 1 Level 2

Cat DEAC

and Conventional Heavy-Duty Coolants Every 250 hours Yearly

Cat ELC

and Commercial EC-1 coolants Optional or every 500 hours Yearly or every 500 hours Note: Check the SCA (Supplemental Coolant Additive) of the conventional coolant at every oil change or at every 250 hours. Perform this check at the interval that occurs first.Refer to your machine OMM for recommendations specific to your machine.S O S Services Coolant Analysis (Level 1)

A coolant analysis (Level 1) is a test of the properties of the coolant.The following properties of the coolant are tested:

Glycol concentration for freeze protection and boil protection

Ability to protect from erosion and corrosion

pH

Conductivity

Visual analysis

Odor analysisThe results are reported, and appropriate recommendations are made.S O S Services Coolant Analysis (Level 2)

A coolant analysis ( Level 2) is a comprehensive chemical evaluation of the coolant. This analysis is also a check of the overall condition of the cooling system.The S O S coolant analysis ( Level 2) has the following features:

Full coolant analysis (Level 1)

Identification of metal corrosion and of contaminants

Identification of buildup of the impurities that cause corrosion

Identification of buildup of the impurities that cause scaling

Determination of the possibility of electrolysis within the cooling system of the engineThe results are reported, and appropriate recommendations are made.For more information on S O S coolant analysis, consult your Caterpillar dealer.