Information injection-pump assembly

BOSCH

F 01G 29X 075

f01g29x075

ZEXEL

104742-7611

1047427611

YANMAR

12991951500

12991951500

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump Compatible For Yanmar 4TNE98 NP-VE4/12F1150RNP2623 VE 104642-7611 129919-51500 1046427611 12991951500 Engine Parts

SDETASOQ Precise control: precise fuel injection, optimized combustion efficiency, reduced fuel consumption, and improved engine power output || Long lifespan and low maintenance: using high-strength wear-resistant alloy materials and corrosion-resistant coatings to reduce maintenance costs and downtime || Stable operation under all operating conditions: tested in extreme environments, continuously stable, and adaptable to various complex road and climate conditions || Silent and efficient operation: Adopting a noise reduction structure, it can maintain quietness even during high-speed operation, without interfering with the driving experience || Fuel Injection Pump Compatible For Yanmar 4TNE98 NP-VE4/12F1150RNP2623 VE 104642-7611 129919-51500 1046427611 12991951500 Engine Parts

SDETASOQ Precise control: precise fuel injection, optimized combustion efficiency, reduced fuel consumption, and improved engine power output || Long lifespan and low maintenance: using high-strength wear-resistant alloy materials and corrosion-resistant coatings to reduce maintenance costs and downtime || Stable operation under all operating conditions: tested in extreme environments, continuously stable, and adaptable to various complex road and climate conditions || Silent and efficient operation: Adopting a noise reduction structure, it can maintain quietness even during high-speed operation, without interfering with the driving experience || Fuel Injection Pump Compatible For Yanmar 4TNE98 NP-VE4/12F1150RNP2623 VE 104642-7611 129919-51500 1046427611 12991951500 Engine Parts

Fuel Injection Pump Compatible For YANMAR 4TNE98 NP-VE4/12F1150RNP2623 VE 104642-7611 129919-51500 1046427611 12991951500 Engine Parts

Xqscvqwfa Part Number:NP-VE4/12F1150RNP2623 VE 104642-7611 129919-51500 1046427611 12991951500 || Easy Installation:Designed for hassle-free replacement with no modifications required. || Enhanced Durability:Robust construction with high-grade materials for long-lasting reliability. || Improved Fuel Efficiency:Maintains consistent fuel pressure for better combustion and reduced emissions. || Premium Quality:Precision-engineered for optimal fuel pressure and flow, ensuring smooth engine performance.

Xqscvqwfa Part Number:NP-VE4/12F1150RNP2623 VE 104642-7611 129919-51500 1046427611 12991951500 || Easy Installation:Designed for hassle-free replacement with no modifications required. || Enhanced Durability:Robust construction with high-grade materials for long-lasting reliability. || Improved Fuel Efficiency:Maintains consistent fuel pressure for better combustion and reduced emissions. || Premium Quality:Precision-engineered for optimal fuel pressure and flow, ensuring smooth engine performance.

High Pressure Diesel VE Injection Fuel Pump Assembly Compatible For 4TNE 104642-7611 104742-7612 NP-VE4 12F1150RNP2623 129919-51500

Liaeyou Ensures a consistent and stable fuel pressure within the vehicle's fuel system to support optimal engine performance. || Regulates the amount of fuel flowing to the engine according to driving conditions and engine requirements. || Avoids situations where the engine runs out of fuel by continuously supplying an adequate fuel supply. || Collaborates with the fuel injection system to atomize and deliver fuel precisely into the engine cylinders. || By providing the right amount of fuel at the right time, it helps enhance the vehicle's overall fuel efficiency.

Liaeyou Ensures a consistent and stable fuel pressure within the vehicle's fuel system to support optimal engine performance. || Regulates the amount of fuel flowing to the engine according to driving conditions and engine requirements. || Avoids situations where the engine runs out of fuel by continuously supplying an adequate fuel supply. || Collaborates with the fuel injection system to atomize and deliver fuel precisely into the engine cylinders. || By providing the right amount of fuel at the right time, it helps enhance the vehicle's overall fuel efficiency.

You can express buy:

USD 396

19-05-2025

19-05-2025

For YANMAR 4TNE98 Engine Diesel Fuel Injection Pump 104742-7611,129919-51501,104642-7611

USD 411.2

19-05-2025

19-05-2025

104642-7611 104742-7612 NP-VE4/12F1150RNP2623 129919-51500 High Pressure Diesel VE Injection Fuel Pump Assembly for YANMAR 4TNE

Images:

USD 411.32

[13-May-2025]

USD 411.32

[13-May-2025]

USD 411.2

[13-May-2025]

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104742-7611 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1750 |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 12.3(125) |

| 10. | NOZZLE-HOLDER | 105078-0050 |

| 11. | NOZZLE | 105007-1580 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0220 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0320 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0300 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-5320 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-6620 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-5820 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2200 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-5100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM D17&5.2T2.8 |

| 48/1. | [1] | 146690-6600 | SHIM D17&5.2T2.9 |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM D17&5.2T3.4 |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM D17&5.2T0.6 |

| 48/1. | [1] | 146690-7400 | SHIM D17&5.2T0.7 |

| 48/1. | [1] | 146690-7500 | SHIM D17&5.2T1.9 |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146401-3020 | HYDRAULIC HEAD |

| 50. | [1] | 146401-3020 | HYDRAULIC HEAD |

| 50. | [1] | 146401-3020 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET |

| 55. | [4] | 146430-3820 | DELIVERY-VALVE ASSEMBLY VE38 |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0220 | FITTING |

| 60. | [4] | 139106-0100 | FLAT-HEAD SCREW |

| 67. | [1] | 146822-2020 | GOVERNOR COVER |

| 67/1. | [1] | 146805-9320 | GOVERNOR COVER |

| 67/2. | [1] | 146515-0320 | CONTROL SHAFT |

| 67/3. | [1] | 146600-0100 | O-RING |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/5. | [1] | 146833-1500 | CONTROL LEVER |

| 67/5B. | [1] | 146833-1600 | CONTROL LEVER |

| 67/5C. | [1] | 146833-1700 | CONTROL LEVER |

| 67/5D. | [1] | 146833-1800 | CONTROL LEVER |

| 67/6. | [2] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 67/6. | [2] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 67/7. | [1] | 013020-6040 | UNION NUT |

| 67/8. | [1] | 146515-1820 | LEVER SHAFT |

| 67/9. | [1] | 146592-0400 | COILED SPRING |

| 67/10. | [1] | 146600-0200 | O-RING |

| 67/11. | [1] | 146602-0100 | PLAIN WASHER |

| 67/12. | [1] | 146540-4000 | CONTROL LEVER |

| 67/12B. | [1] | 146540-4100 | CONTROL LEVER |

| 67/13. | [1] | 146621-1700 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-6400 | BLEEDER SCREW |

| 67/18. | [1] | 146594-1000 | COILED SPRING |

| 67/19. | [1] | 146541-0000 | ANGLE PIECE |

| 67/25. | [2] | 013020-6040 | UNION NUT |

| 67/25. | [2] | 013020-6040 | UNION NUT |

| 67/26. | [1] | 139006-0200 | BLEEDER SCREW |

| 67/64. | [2] | 139306-0400 | PLAIN WASHER |

| 67/69. | [2] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 95. | [1] | 146891-0420 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER |

| 115. | [1] | 146976-3800 | SLIDING SLEEVE |

| 116. | [1] | 146576-0400 | CAP |

| 117/1. | [1] | 146877-0820 | PLUG L=5.0 |

| 117/1. | [1] | 146877-0920 | PLUG L=5.1 |

| 117/1. | [1] | 146877-1020 | PLUG L=5.2 |

| 117/1. | [1] | 146877-1120 | PLUG L=5.3 |

| 117/1. | [1] | 146877-1220 | PLUG L=5.4 |

| 117/1. | [1] | 146877-1320 | PLUG L=5.5 |

| 117/1. | [1] | 146877-1420 | PLUG L=5.6 |

| 117/1. | [1] | 146877-1520 | PLUG L=5.7 |

| 117/1. | [1] | 146877-1620 | PLUG L=5.8 |

| 117/1. | [1] | 146877-1720 | PLUG L=5.9 |

| 117/1. | [1] | 146877-1820 | PLUG L=6.0 |

| 117/1. | [1] | 146877-1920 | PLUG L=6.1 |

| 117/1. | [1] | 146877-2020 | PLUG L=6.2 |

| 117/1. | [1] | 146877-2120 | PLUG L=6.3 |

| 117/1. | [1] | 146877-2220 | PLUG L=6.4 |

| 117/1. | [1] | 146877-2320 | PLUG L=6.5 |

| 117/1. | [1] | 146877-2420 | PLUG L=6.6 |

| 117/1. | [1] | 146877-2520 | PLUG L=6.7 |

| 117/1. | [1] | 146877-2620 | PLUG L=6.8 |

| 117/1. | [1] | 146877-2720 | PLUG L=6.9 |

| 117/1. | [1] | 146877-2820 | PLUG L=7.0 |

| 117/1. | [1] | 146877-2920 | PLUG L=7.1 |

| 117/1. | [1] | 146877-3020 | PLUG L=7.2 |

| 117/1. | [1] | 146877-3120 | PLUG L=7.3 |

| 117/1. | [1] | 146877-3220 | PLUG L=7.4 |

| 117/1. | [1] | 146877-3320 | PLUG L=7.5 |

| 117/1. | [1] | 146877-3420 | PLUG L=7.6 |

| 117/1. | [1] | 146877-3520 | PLUG L=7.7 |

| 117/1. | [1] | 146877-3620 | PLUG L=7.8 |

| 117/1. | [1] | 146877-3720 | PLUG L=7.9 |

| 117/1. | [1] | 146877-3820 | PLUG L=8.0 |

| 117/1. | [1] | 146877-3920 | PLUG L=8.1 |

| 117/1. | [1] | 146877-4020 | PLUG L=8.2 |

| 117/1. | [1] | 146877-4120 | PLUG L=8.3 |

| 117/1. | [1] | 146877-4220 | PLUG L=8.4 |

| 120. | [1] | 146579-9520 | RETAINING PIN |

| 122. | [1] | 146580-3700 | GOVERNOR SPRING |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-1020 | CAPSULE |

| 130/2. | [1] | 139508-0200 | GASKET |

| 130/3. | [1] | 146422-0300 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0620 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146650-5520 | PULLING ELECTROMAGNET STAMP 55 |

| 137. | [2] | 139514-0200 | GASKET |

| 145. | [1] | 146621-4901 | UNION NUT |

| 147. | [1] | 146600-5000 | O-RING |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 233. | [1] | 146662-9920 | WIRE |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-4820 | WIRE |

| 243. | [1] | 146621-4901 | UNION NUT |

| 245. | [3] | 139512-0500 | GASKET |

| 246. | [1] | 146125-0600 | EYE BOLT |

| 247. | [1] | 146677-8020 | PIPE |

| 247. | [1] | 146677-8020 | PIPE |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 800S. | [1] | 146018-6820 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0320 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5820 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 906. | [1] | 146911-1400 | NAMEPLATE |

| 907. | [1] | 029470-4030 | WOODRUFF KEY |

| 908. | [1] | 013121-4140 | UNION NUT |

| 909. | [1] | 029321-4050 | LOCKING WASHER |

Include in #2:

104742-7611

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 01G 29X 075

f01g29x075

ZEXEL

104742-7611

1047427611

YANMAR

12991951500

12991951500

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

With S/T O-ring; S/T OFF. OFF

With S/T O-ring; S/T OFF. OFF

Injection timing adjustment

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

59.8

59.3

60.3

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

54

48.5

59.5

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

59.8

56.3

63.3

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

59.8

58.8

60.8

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

57.2

53.7

60.7

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1313

1313

1313

Average injection quantity

mm3/st.

19.7

15.2

24.2

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1313

1313

1313

Average injection quantity

mm3/st.

19.7

14.7

24.7

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

9.6

7.6

11.6

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

9.6

7.1

12.1

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

62

57

67

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

62

57

67

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity with S/T ON

cm3/min

480

350

610

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure with S/T ON

kPa

637

598

676

Pressure with S/T ON

kgf/cm2

6.5

6.1

6.9

Pressure with S/T OFF

kPa

539

510

568

Pressure with S/T OFF

kgf/cm2

5.5

5.2

5.8

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure with S/T OFF

kPa

539

500

578

Pressure with S/T OFF

kgf/cm2

5.5

5.1

5.9

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke with S/T ON

mm

3.7

3.2

4.2

Timer stroke with S/T OFF

mm

2.5

2.3

2.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

1000

1000

1000

Timer stroke with S/T ON

mm

3.7

3

4.4

Timer stroke with S/T OFF

mm

2.5

2.1

2.9

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_03

Pump speed

r/min

1150

1150

1150

Timer stroke with S/T OFF

mm

3.3

2.7

3.9

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.1

3

3.2

KF dimension

mm

5.3

5.2

5.4

MS dimension

mm

1.8

1.7

1.9

Control lever angle alpha

deg.

14

10

18

Control lever angle beta

deg.

27

22

32

Test data Ex:

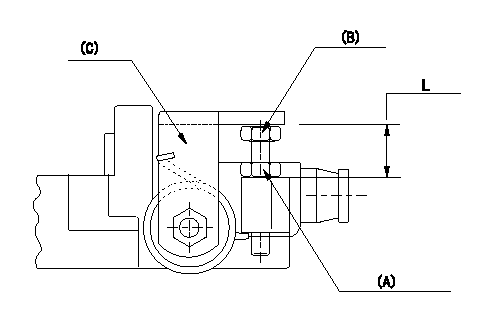

0000001801 STOP LEVER ADJUSTMENT

Adjustment of the stop lever

Adjust the bolt (B) so that the starting injection quantity is as specified, then fix using the nut.

(A) Adjusting nut (Torque T)

(B) Adjusting bolt

(C) Starting injection quantity adjusting lever

----------

T=6~9N-m(0.6~0.9kgf-m)

----------

L=15.0~18.5mm

----------

T=6~9N-m(0.6~0.9kgf-m)

----------

L=15.0~18.5mm

Information:

2. Remove three nuts and washers (1).3. Move Peec unit (2) out of the way. (If so equipped). 4. Remove elbows (5) and pipes (7).5. Remove fuel line brackets (4).6. Remove bolts (6). Remove cover (3). 7. Remove elbows (10). Remove adapters (8) and adapters (9) from the aftercooler core. Remove bolts (11). 8. Move aftercooler core (12) toward the front of the engine and use two people to remove the aftercooler core from the lower aftercooler housing. The weight of the aftercooler core is approximately 29 kg (65 lb). Remove the O-ring seals from the aftercooler core extensions.Install Aftercooler

1. Install O-ring seals (13) on the aftercooler core extensions. Put clean engine oil or glycerin on the seals.2. Use two people to put aftercooler core (12) into position in the lower aftercooler housing. The weight of the aftercooler core is approximately 29 kg (65 lb). 3. Install bolts (11). Put clean engine oil or glycerin on O-ring seal (14) and in bores (15) and (16). 4. Put clean engine oil or glycerin on O-ring seals (17) and adapters (8) and (9). Install adapters (8) and (9) in the aftercooler core. 5. Install elbows (10). 6. Put cover (3) into position on the engine. Install bolts (6).7. Install fuel injection line brackets (4). Tighten bolts (20) to a torque of 4.5 1.1 N m (40 10 lb in).8. Put clean engine oil or glycerin on pipes (7). Install pipes (7) and elbows (5).9. Fill the cooling system with coolant. See Operation & Maintenance Manual for the proper procedure and levels.

1. Install O-ring seals (13) on the aftercooler core extensions. Put clean engine oil or glycerin on the seals.2. Use two people to put aftercooler core (12) into position in the lower aftercooler housing. The weight of the aftercooler core is approximately 29 kg (65 lb). 3. Install bolts (11). Put clean engine oil or glycerin on O-ring seal (14) and in bores (15) and (16). 4. Put clean engine oil or glycerin on O-ring seals (17) and adapters (8) and (9). Install adapters (8) and (9) in the aftercooler core. 5. Install elbows (10). 6. Put cover (3) into position on the engine. Install bolts (6).7. Install fuel injection line brackets (4). Tighten bolts (20) to a torque of 4.5 1.1 N m (40 10 lb in).8. Put clean engine oil or glycerin on pipes (7). Install pipes (7) and elbows (5).9. Fill the cooling system with coolant. See Operation & Maintenance Manual for the proper procedure and levels.