Information injection-pump assembly

BOSCH

F 01G 0V0 001

f01g0v0001

ZEXEL

101609-3640

1016093640

KOMATSU

4063209

4063209

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump 101609-3640 1016093640 Suitable for Komatsu 6D102 Engine PC200-7 PC220-7

OfkZynodor Product name:Fuel Injection Pump || Part Number:101609-3640 1016093640 || APPlication:Suitable for Komatsu 6D102 Engine PC200-7 PC220-7 || Please make sure to carefully compare the photos and check the part numbers before making the purchase. If you are unable to confirm your engine model or part number, please leave us a message and we will assist you in confirming that the product you purchase is the one you need. || Your order is not merely a single purchase but the beginning of a cooperative journey, aiming to ensure the safe and smooth operation of your vehicle. We are proud to offer you reliable precision engineering components and unparalleled services.

OfkZynodor Product name:Fuel Injection Pump || Part Number:101609-3640 1016093640 || APPlication:Suitable for Komatsu 6D102 Engine PC200-7 PC220-7 || Please make sure to carefully compare the photos and check the part numbers before making the purchase. If you are unable to confirm your engine model or part number, please leave us a message and we will assist you in confirming that the product you purchase is the one you need. || Your order is not merely a single purchase but the beginning of a cooperative journey, aiming to ensure the safe and smooth operation of your vehicle. We are proud to offer you reliable precision engineering components and unparalleled services.

Fuel Injection Pump 101609-3640 1016093640 For Komatsu 6D102 Engine PC200-7 PC220-7

oiasdfhjdg Product name:Fuel Injection Pump || Part Number:101609-3640 1016093640 || APPlication:For Komatsu 6D102 Engine PC200-7 PC220-7 || 1.Please carefully compare the OE numbers before purchasing the product to match your original parts and avoid wasting your valuable time. || 2.Please ensure to provide us with the correct, accurate, and detailed delivery address and contact information

oiasdfhjdg Product name:Fuel Injection Pump || Part Number:101609-3640 1016093640 || APPlication:For Komatsu 6D102 Engine PC200-7 PC220-7 || 1.Please carefully compare the OE numbers before purchasing the product to match your original parts and avoid wasting your valuable time. || 2.Please ensure to provide us with the correct, accurate, and detailed delivery address and contact information

Fuel Injection Pump 101609-3640 1016093640 Suitable for Komatsu 6D102 Engine PC200-7 PC220-7

TuneCrumph 🚕Product name:Fuel Injection Pump || 🚕Part Number:101609-3640 1016093640 || 🚕APPlication:Suitable for Komatsu 6D102 Engine PC200-7 PC220-7 || 🚕Attention: Dear buyers, precise matching of auto parts is the prerequisite for safe installation! To avoid the problems such as returns, exchanges or installation hazards caused by incorrect model selection, please carefully read and verify the model before placing your order. Thank you for your support! || 🚕NOTE:We are fully aware that your satisfaction is the driving force for the growth of our brand. Thank you for giving us the opportunity to serve you. If there is anything we haven't covered, please give us your feedback directly. Your suggestions are extremely precious to us!

TuneCrumph 🚕Product name:Fuel Injection Pump || 🚕Part Number:101609-3640 1016093640 || 🚕APPlication:Suitable for Komatsu 6D102 Engine PC200-7 PC220-7 || 🚕Attention: Dear buyers, precise matching of auto parts is the prerequisite for safe installation! To avoid the problems such as returns, exchanges or installation hazards caused by incorrect model selection, please carefully read and verify the model before placing your order. Thank you for your support! || 🚕NOTE:We are fully aware that your satisfaction is the driving force for the growth of our brand. Thank you for giving us the opportunity to serve you. If there is anything we haven't covered, please give us your feedback directly. Your suggestions are extremely precious to us!

You can express buy:

USD 3131.13

28-06-2025

28-06-2025

Engine Parts 6BT5.9 Injection Pump 4063845 4063208 4063209 Fuel Injection Pump 6738-71-1520 101609-3750 1016093750

Images:

US $1685.00

[22-Dec-2016]

USD 1800

[08-Mar-2017]

Service parts 101609-3640 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

4063212

12.

Open Pre:MPa(Kqf/cm2)

22.0{224}

15.

NOZZLE SET

Include in #1:

101609-3640

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 01G 0V0 001

f01g0v0001

ZEXEL

101609-3640

1016093640

KOMATSU

4063209

4063209

Zexel num

Bosch num

Firm num

Name

101609-3640

F 01G 0V0 001

4063209 KOMATSU

INJECTION-PUMP ASSEMBLY

6BTAA K 14BE INJECTION PUMP ASSY PE6A PE

6BTAA K 14BE INJECTION PUMP ASSY PE6A PE

101609-3640

F 01G 0V0 001

6738711210 KOMATSU

INJECTION-PUMP ASSEMBLY

6BTAA K 14BE INJECTION PUMP ASSY PE6A PE

6BTAA K 14BE INJECTION PUMP ASSY PE6A PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.6

2.55

2.65

Rack position

After adjusting injection quantity. R=A

After adjusting injection quantity. R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

12

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

128.5

127.5

129.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.8+-0.5

Pump speed

r/min

525

525

525

Average injection quantity

mm3/st.

9.5

8.5

10.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

D

Rack position

10.3

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

45

55

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

E

Rack position

12.2++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

120

115

125

Fixing the lever

*

Boost pressure

kPa

53.3

53.3

Boost pressure

mmHg

400

400

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

850

850

850

Rack position

10.3

Boost pressure

kPa

29.3

26.6

32

Boost pressure

mmHg

220

200

240

Boost compensator adjustment_02

Pump speed

r/min

850

850

850

Rack position

R1(12)

Boost pressure

kPa

40

40

40

Boost pressure

mmHg

300

300

300

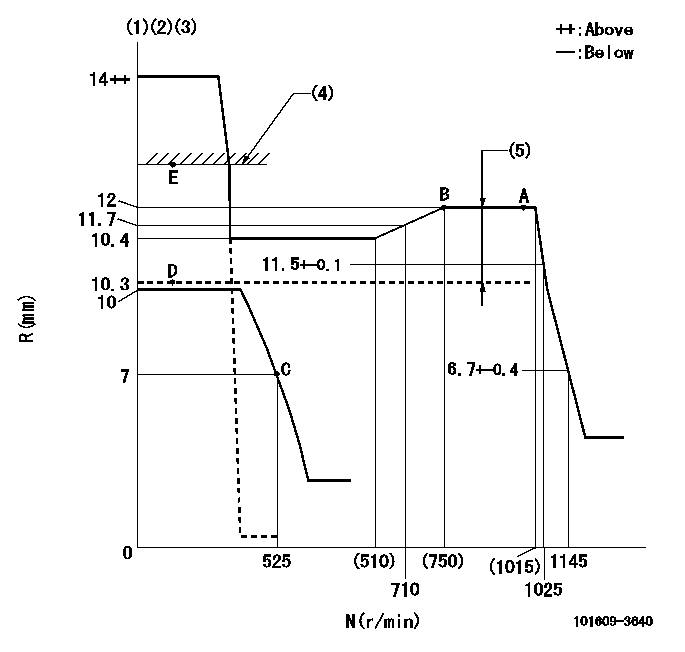

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)It is not necessary to supply hydraulic pressure because the specification is for the hydraulic ACT normally ON.

(4)RACK LIMIT

(5)Boost compensator stroke: BCL

----------

K=12 BCL=(1.7)mm

----------

----------

K=12 BCL=(1.7)mm

----------

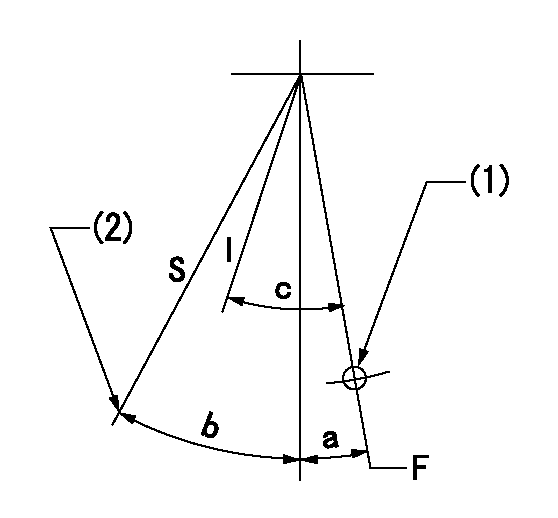

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Use hole at R = aa (middle hole)

(2)Stopper bolt setting

----------

aa=77mm

----------

a=7deg+-5deg b=31deg+-3deg c=28deg+-5deg

----------

aa=77mm

----------

a=7deg+-5deg b=31deg+-3deg c=28deg+-5deg

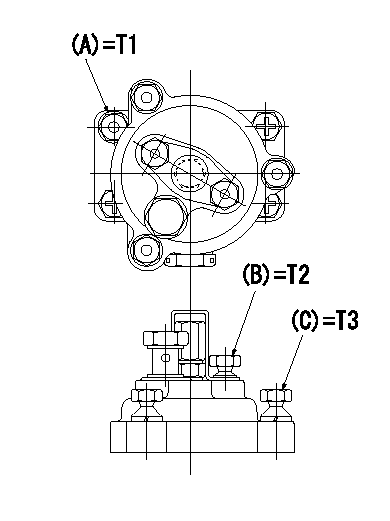

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(1)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

(3)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T3)

----------

T1=7.16~9.12N-m(0.73~0.93kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m) T3=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=7.16~9.12N-m(0.73~0.93kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m) T3=2.9~4.4N-m(0.3~0.45kgf-m)

----------

0000001601 I/P WITH LOAD PLUNGER ADJ

Adjusting procedure for load plunger equipped pump with RSV (cam lock) governor (see service information S.I. 434 for details).

At cam lift h+-0.01, set the camshaft c deg from the * mark in accordance with the timing adjustment procedure.

2. Align the flyweight's timing tooth position and the lock pin groove and then fully tighten the flyweight to the camshaft. Then, remove the lock pin.

3. Adjust the maximum variation between cylinders and injection quantity.

4. Adjust using the pre-stroke adjusting shim so that the pre-stroke value is the value for 4/4 load (standard point A).

5. After adjusting the pre-stroke, reconfirm that the injection quantity and the maximum variation between cylinders are as specified.

6. At delivery, again fix the flyweight using the lock pin.

----------

h=2.6mm c=5deg30min+-30min

----------

----------

h=2.6mm c=5deg30min+-30min

----------

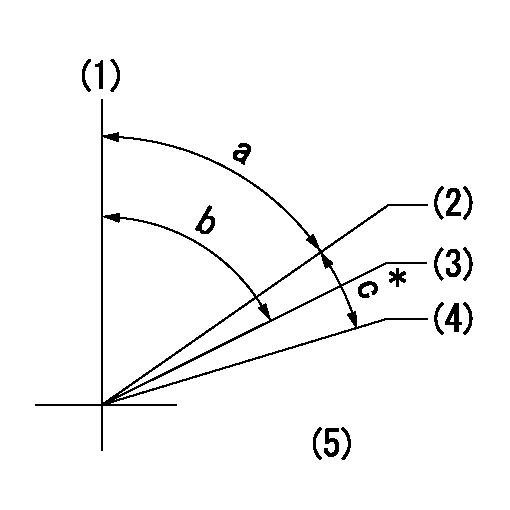

Timing setting

(1)Pump vertical direction

(2)Key groove position for No. 1 cylinder's cam lift h = cc (at BTDC aa).

(3)Key groove position for No. 1 cylinder's beginning of injection (at point A after injection quantity adjustment).

(4)Position of the key groove of the No. 1 cylinder at B.T.D.C. bb (fix the governor flyweight at this position for delivery).

(5)B.T.D.C.: aa

----------

aa=11deg bb=0deg cc=2.6+-0.1mm

----------

a=55deg18min+-3deg b=55deg18min+-3deg13min48sec c=5deg30min+-30min

----------

aa=11deg bb=0deg cc=2.6+-0.1mm

----------

a=55deg18min+-3deg b=55deg18min+-3deg13min48sec c=5deg30min+-30min

Information:

Start By:a. remove fuel injection lines 1. Remove bolt (1) and clamp (2) from the fuel injection nozzles to be removed.2. Install Tool (A) with the inside lip of the puller on the lower stepped diameter of the nozzle and the tip of the button in the threaded hole for bolt (1).

Do not exceed a torque of 17 N m (150 lb in) on the screw of Tool (A) during removal of the nozzle. Added force can cause the stem of the nozzle to bend or break off.

3. Tighten the screw of Tool (A) to a maximum torque of 17 N m (150 lb in) to remove fuel injection nozzle (3).4. If the fuel injection nozzle can not be removed with a maximum torque of 17 N m (150 lb in) on the screw of Tool (A), remove Tool (A).

Typical Example5. Remove the protective cap from fuel injection nozzle (3), and install Tool (B) as shown.

Hold Tool (B) so the center line of the tool is in alignment with the centerline of fuel injection nozzle (3). This will prevent distortion of the nozzle which can cause it to bend or break off during removal.

6. Remove the fuel injection nozzle with Tool (B).7. If Tool (B) was used to remove the fuel injection nozzle, replace the nozzle.8. If Tool (A) was used to remove the fuel injection nozzle, remove the carbon dam seal on the end of the nozzle.Install Fuel Injection Nozzle

1. Use Tool (C) to clean the bore for the fuel injection nozzle. Use an open end wrench or tap driver to turn Tool (C).2. Make reference to Special Instruction, Form No. SEHS7292, for the use of Tool (D). Clean the fuel injection nozzle with Tool (D). 3. Install a new seal (4) on fuel injection nozzle (3).4. Put carbon dam seal (5) on the small end of Tool (E). Expand the carbon dam seal by sliding it to the large end. Put Tool (E) against the fuel injection nozzle. Slide carbon dam seal (5) off Tool (E) on to the nozzle. Slide the carbon dam seal into position in the groove on the nozzle as shown. 5. Put fuel injection nozzle (3) in position in the cylinder head. Install clamp (2) and bolt (1) to hold the nozzle in position.End By:a. install fuel injection lines

Do not exceed a torque of 17 N m (150 lb in) on the screw of Tool (A) during removal of the nozzle. Added force can cause the stem of the nozzle to bend or break off.

3. Tighten the screw of Tool (A) to a maximum torque of 17 N m (150 lb in) to remove fuel injection nozzle (3).4. If the fuel injection nozzle can not be removed with a maximum torque of 17 N m (150 lb in) on the screw of Tool (A), remove Tool (A).

Typical Example5. Remove the protective cap from fuel injection nozzle (3), and install Tool (B) as shown.

Hold Tool (B) so the center line of the tool is in alignment with the centerline of fuel injection nozzle (3). This will prevent distortion of the nozzle which can cause it to bend or break off during removal.

6. Remove the fuel injection nozzle with Tool (B).7. If Tool (B) was used to remove the fuel injection nozzle, replace the nozzle.8. If Tool (A) was used to remove the fuel injection nozzle, remove the carbon dam seal on the end of the nozzle.Install Fuel Injection Nozzle

1. Use Tool (C) to clean the bore for the fuel injection nozzle. Use an open end wrench or tap driver to turn Tool (C).2. Make reference to Special Instruction, Form No. SEHS7292, for the use of Tool (D). Clean the fuel injection nozzle with Tool (D). 3. Install a new seal (4) on fuel injection nozzle (3).4. Put carbon dam seal (5) on the small end of Tool (E). Expand the carbon dam seal by sliding it to the large end. Put Tool (E) against the fuel injection nozzle. Slide carbon dam seal (5) off Tool (E) on to the nozzle. Slide the carbon dam seal into position in the groove on the nozzle as shown. 5. Put fuel injection nozzle (3) in position in the cylinder head. Install clamp (2) and bolt (1) to hold the nozzle in position.End By:a. install fuel injection lines

Have questions with 101609-3640?

Group cross 101609-3640 ZEXEL

Komatsu

Komatsu

Komatsu

101609-3640

F 01G 0V0 001

4063209

INJECTION-PUMP ASSEMBLY

6BTAA

6BTAA

101609-3640

F 01G 0V0 001

6738711210

INJECTION-PUMP ASSEMBLY

6BTAA

6BTAA