Information injection-pump assembly

BOSCH

9 400 613 464

9400613464

ZEXEL

101495-3453

1014953453

KOMATSU

6204711170

6204711170

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Nayuank Fuel Injection Pump 104641-7260 6204-71-1170 1046417260 Fits For Cummins Engine QSB3.3 B3.3

Nayuank Part Name: Fuel Injection Pump || Part Number: 104641-7260 6204-71-1170 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Engine Model: QSB3.3 || Applicable: Fits For Cummins Engine QSB3.3 B3.3 || Package included: 1pcs Fuel Injection Pump 104641-7260 6204-71-1170 1046417260

Nayuank Part Name: Fuel Injection Pump || Part Number: 104641-7260 6204-71-1170 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Engine Model: QSB3.3 || Applicable: Fits For Cummins Engine QSB3.3 B3.3 || Package included: 1pcs Fuel Injection Pump 104641-7260 6204-71-1170 1046417260

Fuel Injection Pump 9400613464 6204-71-1170 for Komatsu 4D95L Cummins QSB3.3 B3.3 Engine

FGNTWP Part Number:6204-71-1170, 6204711170, 9400613464, 9 400 613 464, 101495-3453, 1014953453 || Applications:for Komatsu 4D95L Cummins QSB3.3 B3.3 Engine

FGNTWP Part Number:6204-71-1170, 6204711170, 9400613464, 9 400 613 464, 101495-3453, 1014953453 || Applications:for Komatsu 4D95L Cummins QSB3.3 B3.3 Engine

You can express buy:

USD 1407.05

09-05-2025

09-05-2025

New fuel injection pump 6204-71-1120 C6204711360 6204-71-1170 Zexel A 104641-7260 for Cummins QSB3.3 B3.3 without turbocharger

Service parts 101495-3453 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 613 464

9400613464

ZEXEL

101495-3453

1014953453

KOMATSU

6204711170

6204711170

Zexel num

Bosch num

Firm num

Name

101495-3453

9 400 613 464

6204711170 KOMATSU

INJECTION-PUMP ASSEMBLY

4D95L K 14BC INJECTION PUMP ASSY PE4A,5A, PE

4D95L K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-4-3

Pre-stroke

mm

3.2

3.15

3.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cyl.1-2 deg. 90 89.5 90.5

Cyl.1-2 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cal 1-3 deg. 270 269.5 270.5

Cal 1-3 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.9

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

68.5

67.5

69.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.3+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

8

7

9

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Test data Ex:

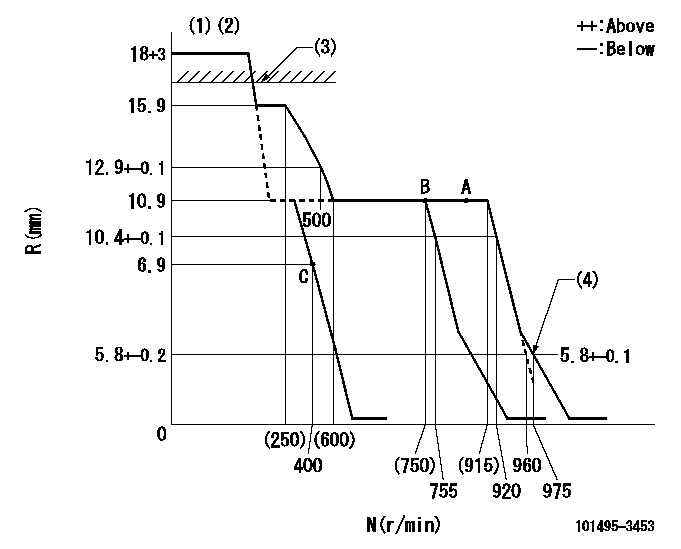

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK CAP: R1

(4)Set idle sub-spring

----------

K=11 R1=(17.5)mm

----------

----------

K=11 R1=(17.5)mm

----------

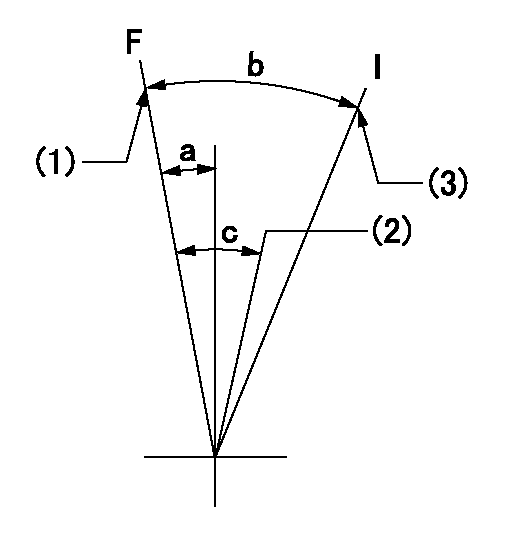

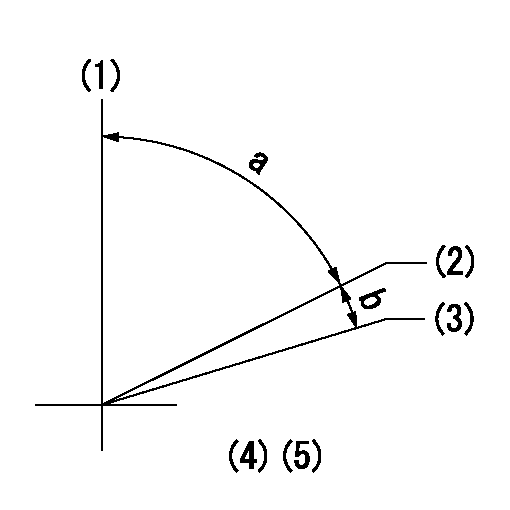

Speed control lever angle

F:Full speed

I:Idle

(1)Set the pump speed at aa. ( At delivery )

(2)Set the pump speed at bb.

(3)Stopper bolt setting

----------

aa=920r/min bb=755r/min

----------

a=3deg+-5deg b=25deg+-5deg c=7deg+-5deg

----------

aa=920r/min bb=755r/min

----------

a=3deg+-5deg b=25deg+-5deg c=7deg+-5deg

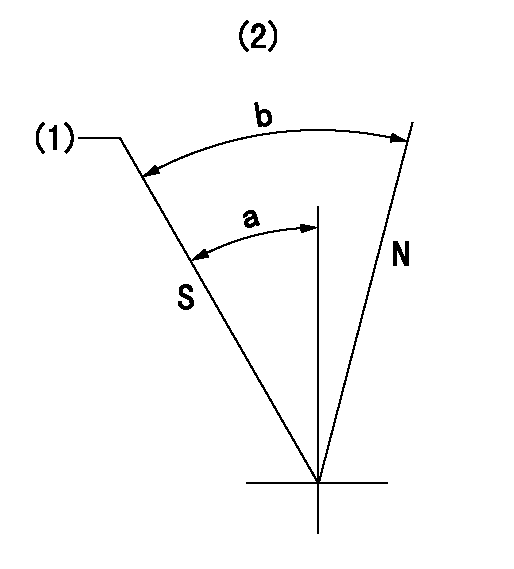

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa, speed = bb (stamp at delivery)

(2)No return spring

----------

aa=1-0.5mm bb=0r/min

----------

a=27.5deg+-5deg b=(55deg)

----------

aa=1-0.5mm bb=0r/min

----------

a=27.5deg+-5deg b=(55deg)

Timing setting

(1)Pump vertical direction

(2)Position of key groove at No 1 cylinder's beginning of injection

(3)Stamp aligning marks on the pump housing flange.

(4)-

----------

----------

a=58deg+-3deg b=2deg+-30min

----------

----------

a=58deg+-3deg b=2deg+-30min

Information:

Use only distillate fuels (ASTM No. 1 or No. 2 Fuel Oil, or No. 1D or No. 2D Diesel Fuel Oil) with a minimum cetane number of 35. Heavier oil is generally preferable because of its higher energy content. The more expensive premium fuels such as No. 1 fuel oil are not necessary for normal operating conditions. In extreme cold temperature, use No. 1 fuel oil or 1D diesel fuel.In selecting a fuel, note that distillate fuels are especially desirable because the fuel is heated to a vaporous state and condensed, thus eliminating sediment and residue.There is considerable variation in the composition of fuels distributed under the No. 2 grade classifications. For desirable engine service it is most important to give special attention to cetane No., water and sediment, pour point, cloud point and sulphur content. USE THE LOWEST PRICE DISTILLATE FUEL WHICH MEETS THE FOLLOWING REQUIREMENTS.Cetane No. ... 35 minimumWater and Sediment ... 0.1% maximumPour Point ... 10F° (-12C°) below ambient temperatureCloud Point ... No higher than ambient temperatureSulphur Content* ... Adjust oil change periodGravity ... 32-40 A.P.I. at 60°F (15°C)*See the topic SULPHUR CONTENT. Cetane No.: This is an indication of a fuel's ignition quality and should not be less than 35 for this engine. For high altitude operation or cold weather starting, a higher cetane number is required. Water and Sediment: A good clean fuel will contain no more than 0.1% sediment and water. Dirty fuels lead to early filter plugging and in addition can result in the formation of gums and resins reducing filter and engine life. Pour Point: The pour point of the fuel has no effect on engine performance, as long as the fuel is fluid enough to flow from the fuel tank to the engine. The pour point of the fuel should be at least 10F° (-12C°) below the lowest atmospheric temperature at which the engine must start and operate. In extremely cold temperatures it may be necessary to use No. 1 fuel or No. 1D diesel fuel. Cloud Point: Cloud point is the temperature at which wax crystals become visible and is generally above the pour point of the fuel. The cloud point should be no higher than the lowest atmospheric temperature at which the engine must start to keep the fuel filter elements from plugging with wax crystals. Sulphur Content: As sulphur content increases, the crankcase oil change periods should be reduced. Fuel containing .4% or less sulphur content, use normal oil change periods. If the fuel contains .4% to 1.0% sulphur, oil change periods should be reduced to one-half normal time. If the fuel contains more than 1.0% sulphur, oil change periods should be reduced to one-fourth normal time. Gravity: Gravity is the measurement of heat units in a certain amount of fuel. The heavier the fuel (the lower the number) the more heat units per volume. If a fuel with a higher A.P.I. gravity is used the power produced will be

Have questions with 101495-3453?

Group cross 101495-3453 ZEXEL

Komatsu

Komatsu

Komatsu

Komatsu

Komatsu

Komatsu

Komatsu

101495-3453

9 400 613 464

6204711170

INJECTION-PUMP ASSEMBLY

4D95L

4D95L