Information injection-pump assembly

BOSCH

F 019 Z10 947

f019z10947

ZEXEL

101405-3350

1014053350

KOMATSU

4063968

4063968

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump 4063968 for Cummins 4B3.9 Engine Hyundai R140L R140W-7 R140LC-9S R140W-9S

ADPelcote Part number:4063968 || Applications:for Cummins 4B3.9 Engine Hyundai R140L R140W-7 R140LC-9S R140W-9S

ADPelcote Part number:4063968 || Applications:for Cummins 4B3.9 Engine Hyundai R140L R140W-7 R140LC-9S R140W-9S

Fuel Injection Pump 101405-3350 F019Z10947 Compatible for Komatsu Engine SAA4D102 Zexel

Gvgsgtyu 101405-3350 F019Z10947 SAA4D102 || Easy installation: No complex debugging process required, users can use it directly, greatly saving installation time and labor costs. || Easy to maintain: The product design emphasizes practicality, easy disassembly and cleaning, effectively reducing maintenance costs and time. || Reduce vibration: During the operation of the fuel pump, it can effectively reduce vibration transmission, ensure smooth operation of the equipment, and reduce noise and wear. || Long lifespan: Through advanced manufacturing processes and high-quality materials, the service life of fuel pumps has been effectively extended, improving the overall integrity of the equipment.

Gvgsgtyu 101405-3350 F019Z10947 SAA4D102 || Easy installation: No complex debugging process required, users can use it directly, greatly saving installation time and labor costs. || Easy to maintain: The product design emphasizes practicality, easy disassembly and cleaning, effectively reducing maintenance costs and time. || Reduce vibration: During the operation of the fuel pump, it can effectively reduce vibration transmission, ensure smooth operation of the equipment, and reduce noise and wear. || Long lifespan: Through advanced manufacturing processes and high-quality materials, the service life of fuel pumps has been effectively extended, improving the overall integrity of the equipment.

Service parts 101405-3350 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

22.0{224}

15.

NOZZLE SET

Cross reference number

BOSCH

F 019 Z10 947

f019z10947

ZEXEL

101405-3350

1014053350

KOMATSU

4063968

4063968

Zexel num

Bosch num

Firm num

Name

101405-3350

F 019 Z10 947

4063968 KOMATSU

INJECTION-PUMP ASSEMBLY

SAA4D102 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

SAA4D102 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

101405-3350

F 019 Z10 947

6737711510 KOMATSU

INJECTION-PUMP ASSEMBLY

SAA4D102 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

SAA4D102 K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.7

2.65

2.75

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.4

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

117.5

116.5

118.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

66.7

66.7

Boost pressure

mmHg

500

500

Hydraulic cylinder ON

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.4+-0.5

Pump speed

r/min

525

525

525

Average injection quantity

mm3/st.

10

9

11

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Hydraulic cylinder ON

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

E

Rack position

10.8++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

85

95

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Hydraulic cylinder OFF

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

850

850

850

Rack position

(8.5)

Boost pressure

kPa

21.3

18.6

24

Boost pressure

mmHg

160

140

180

Boost compensator adjustment_02

Pump speed

r/min

850

850

850

Rack position

R1(10.4)

Boost pressure

kPa

53.3

53.3

53.3

Boost pressure

mmHg

400

400

400

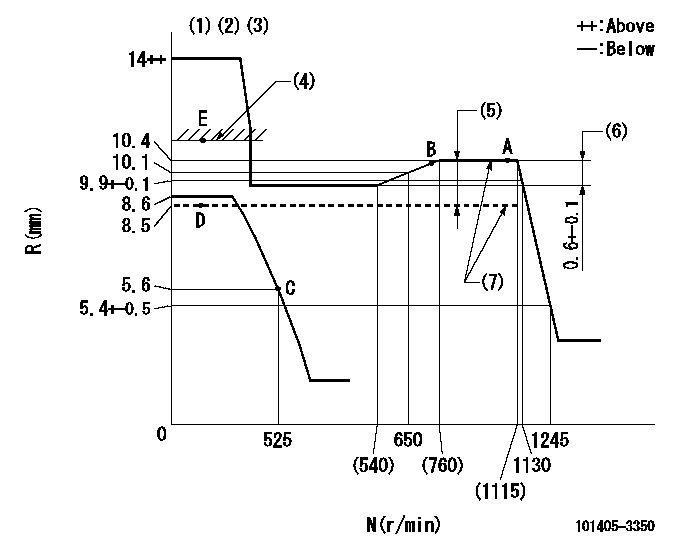

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Adjust the secondary timing before adjusting the governor.

(4)RACK LIMIT (When hydraulic cylinder is OFF)

(5)Boost compensator stroke: BCL

(6)Rack difference between N = N1 and N = N2

(7)When hydraulic cylinder ON: P1

----------

K=13 BCL=(1.9)mm N1=1100r/min N2=400r/min P1=127+-10kPa(1.3+-0.1kgf/cm2)

----------

----------

K=13 BCL=(1.9)mm N1=1100r/min N2=400r/min P1=127+-10kPa(1.3+-0.1kgf/cm2)

----------

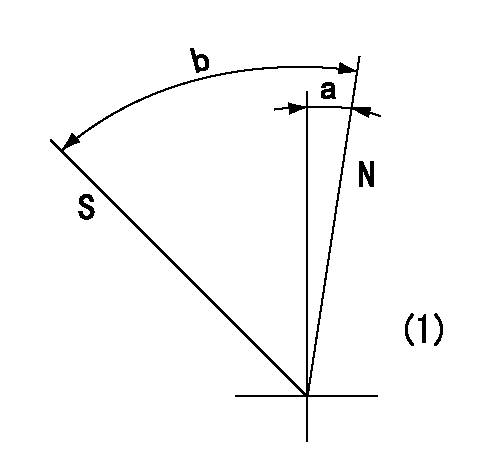

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=80mm

----------

a=11deg+-5deg b=31deg+-5deg

----------

aa=80mm

----------

a=11deg+-5deg b=31deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

----------

----------

a=0deg+-5deg b=53deg+-5deg

----------

----------

a=0deg+-5deg b=53deg+-5deg

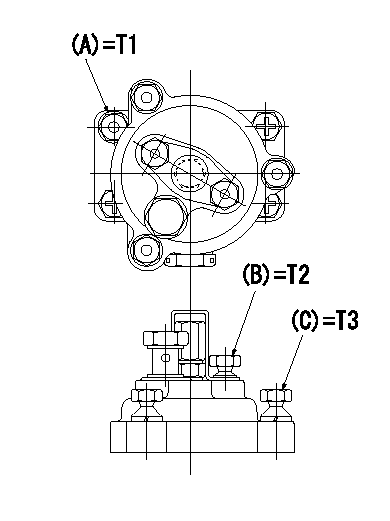

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(1)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

(3)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T3)

----------

T1=7.16~9.12N-m(0.73~0.93kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m) T3=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=7.16~9.12N-m(0.73~0.93kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m) T3=2.9~4.4N-m(0.3~0.45kgf-m)

----------

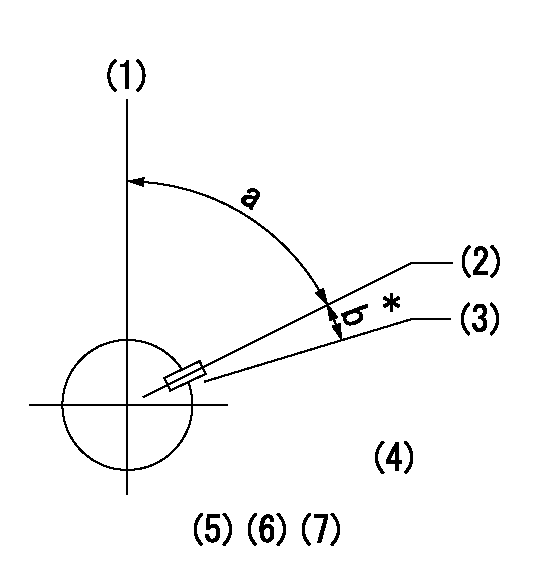

Timing setting

(1)Pump vertical direction

(2)Key groove position at No. 1 cylinder's beginning of injection position (at BTDC: aa).

(3)Position of the key groove of the No. 1 cylinder at B.T.D.C. bb (fix the governor flyweight at this position for delivery).

(4)B.T.D.C.: aa

(5)At second timing adjustment, set the camshaft at the * position and tighten the flyweight locknut.

(6)Align the flyweight's timing gear position with the lockpin groove and then fully tighten the flyweight to the camshaft.

(7)Remove the lock pin and adjust the governor. Reinstall the lock pin to fix the flyweight for delivery.

----------

aa=11deg bb=0deg

----------

a=55deg48min+-3deg b=5deg30min+-30min

----------

aa=11deg bb=0deg

----------

a=55deg48min+-3deg b=5deg30min+-30min

Information:

Adjust Alternator Belts

3. Loosen the mounting pivot bolt (1). Loosen the adjustment nut(s) (2).4. Adjust the alternator in or out by either tightening or loosening adjustment nut(s) as required to obtain the correct adjustment.5. Tighten bolts (1) and (2). Check the belt tension. Install the belt guard.If new belts are installed, check belt adjustment again after 30 minutes of engine operation. Repeat belt tightening if required.Adjust Fan Drive Belts

1. Loosen bolts holding the fan mounting plate to the engine.2. Loosen locknut and turn adjusting screw until the belts are properly adjusted.3. Tighten bolts and locknut.4. Check the belt adjustment. If adjustment is not correct, repeat steps 1 through 3.Inspect/Replace Hoses and Clamps

Hose replacement prior to failure is a good preventive maintenance practice. Replacing a hose before it fails reduces the chances for unscheduled downtime. By replacing a hose that is cracked, soft or leaking, major repairs will be avoided that could result in a severe engine overheating problem.* Inspect all hoses for leaks due to cracking, softness and loose clamps.* Replace hoses that are cracked or soft and tighten loose clamps.Before Replacing Hoses

1. Loosen the cooling system filler cap slowly to relieve any pressure and remove the cap.2. Drain the coolant from the cooling system to a level below the hose being replaced. Remove the hose clamps, disconnect the old hose and replace with a new hose. Install hose clamps. See the Torque for Standard Hose Clamps chart in the Torque Specifications section of this publication for the appropriate torque.After Replacing Hoses

Refer to the Cooling System Specifications section in this publication for information about cooling system requirements.3. Add proper coolant mixture to the cooling system. Fill system to the proper level. Install the filler cap. Start the engine and inspect for cooling system leaks.4. Check coolant temperature reading frequently for proper operating temperature.Engine Air Cleaner

Never service the air cleaner with the engine running since this will allow dirt to enter the engine. Check the inlet piping for leaks. Make all repairs to inlet piping immediately, as dirt and debris could enter the engine causing damage to the turbocharger and engine components.Clean or replace elements using these recommendations and/or your weather and operating conditions, or when required by the restriction indicator.

Replace

Regular service intervals, along with close visual inspection of the air cleaners are necessary for proper cleaning of the engine inlet air. The interval will vary with the weather and operating conditions. It will be necessary to service the air cleaners more frequently in salty, dry weather conditions or where airborne dust and debris is present. In damp weather conditions the service interval may be extended, however the elements should be replaced EVERY YEAR.Visual inspection of the gaskets and seals is important to keep dust from bypassing the cleaner elements. If the gaskets and seals or the element pleats are damaged, replace them. Extra filter elements should be kept on hand for replacement or for use while elements are being cleaned. Refer to topic Air Cleaner Indicator in the

3. Loosen the mounting pivot bolt (1). Loosen the adjustment nut(s) (2).4. Adjust the alternator in or out by either tightening or loosening adjustment nut(s) as required to obtain the correct adjustment.5. Tighten bolts (1) and (2). Check the belt tension. Install the belt guard.If new belts are installed, check belt adjustment again after 30 minutes of engine operation. Repeat belt tightening if required.Adjust Fan Drive Belts

1. Loosen bolts holding the fan mounting plate to the engine.2. Loosen locknut and turn adjusting screw until the belts are properly adjusted.3. Tighten bolts and locknut.4. Check the belt adjustment. If adjustment is not correct, repeat steps 1 through 3.Inspect/Replace Hoses and Clamps

Hose replacement prior to failure is a good preventive maintenance practice. Replacing a hose before it fails reduces the chances for unscheduled downtime. By replacing a hose that is cracked, soft or leaking, major repairs will be avoided that could result in a severe engine overheating problem.* Inspect all hoses for leaks due to cracking, softness and loose clamps.* Replace hoses that are cracked or soft and tighten loose clamps.Before Replacing Hoses

1. Loosen the cooling system filler cap slowly to relieve any pressure and remove the cap.2. Drain the coolant from the cooling system to a level below the hose being replaced. Remove the hose clamps, disconnect the old hose and replace with a new hose. Install hose clamps. See the Torque for Standard Hose Clamps chart in the Torque Specifications section of this publication for the appropriate torque.After Replacing Hoses

Refer to the Cooling System Specifications section in this publication for information about cooling system requirements.3. Add proper coolant mixture to the cooling system. Fill system to the proper level. Install the filler cap. Start the engine and inspect for cooling system leaks.4. Check coolant temperature reading frequently for proper operating temperature.Engine Air Cleaner

Never service the air cleaner with the engine running since this will allow dirt to enter the engine. Check the inlet piping for leaks. Make all repairs to inlet piping immediately, as dirt and debris could enter the engine causing damage to the turbocharger and engine components.Clean or replace elements using these recommendations and/or your weather and operating conditions, or when required by the restriction indicator.

Replace

Regular service intervals, along with close visual inspection of the air cleaners are necessary for proper cleaning of the engine inlet air. The interval will vary with the weather and operating conditions. It will be necessary to service the air cleaners more frequently in salty, dry weather conditions or where airborne dust and debris is present. In damp weather conditions the service interval may be extended, however the elements should be replaced EVERY YEAR.Visual inspection of the gaskets and seals is important to keep dust from bypassing the cleaner elements. If the gaskets and seals or the element pleats are damaged, replace them. Extra filter elements should be kept on hand for replacement or for use while elements are being cleaned. Refer to topic Air Cleaner Indicator in the

Have questions with 101405-3350?

Group cross 101405-3350 ZEXEL

Komatsu

Komatsu

Komatsu

101405-3350

F 019 Z10 947

4063968

INJECTION-PUMP ASSEMBLY

SAA4D102

SAA4D102

101405-3350

F 019 Z10 947

6737711510

INJECTION-PUMP ASSEMBLY

SAA4D102

SAA4D102