Information injection-pump assembly

BOSCH

9 400 614 057

9400614057

ZEXEL

101405-3220

1014053220

KOMATSU

3863983

3863983

Rating:

Include in #1:

101609-9173

as _

Cross reference number

BOSCH

9 400 614 057

9400614057

ZEXEL

101405-3220

1014053220

KOMATSU

3863983

3863983

Zexel num

Bosch num

Firm num

Name

9 400 614 057

3863983 KOMATSU

INJECTION-PUMP ASSEMBLY

S4D102E K 14BC INJECTION PUMP ASSY PE4A,5A, PE

S4D102E K 14BC INJECTION PUMP ASSY PE4A,5A, PE

9 400 614 057

6732711420 KOMATSU

INJECTION-PUMP ASSEMBLY

S4D102E K 14BC INJECTION PUMP ASSY PE4A,5A, PE

S4D102E K 14BC INJECTION PUMP ASSY PE4A,5A, PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.5

2.45

2.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.7

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

97.5

96.5

98.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

46.7

46.7

Boost pressure

mmHg

350

350

Hydraulic cylinder ON

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

6.8+-0.5

Pump speed

r/min

475

475

475

Average injection quantity

mm3/st.

11.5

10.5

12.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Hydraulic cylinder ON

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

E

Rack position

9.9++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

95

105

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Hydraulic cylinder OFF

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

750

750

750

Rack position

R1-1.3

Boost pressure

kPa

13.3

10.6

16

Boost pressure

mmHg

100

80

120

Boost compensator adjustment_02

Pump speed

r/min

750

750

750

Rack position

R1(9.7)

Boost pressure

kPa

33.3

33.3

33.3

Boost pressure

mmHg

250

250

250

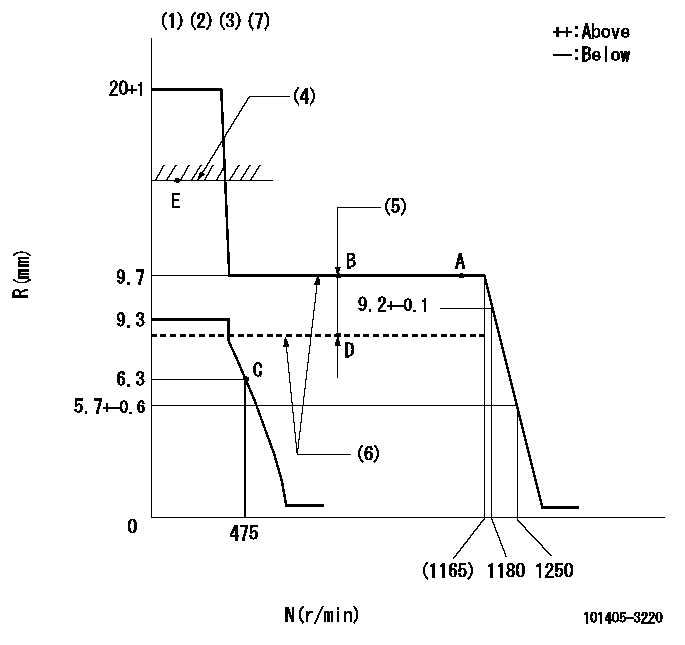

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Deliver without the torque control spring operating.

(4)RACK LIMIT (When hydraulic cylinder is OFF)

(5)Boost compensator stroke: BCL

(6)When hydraulic cylinder ON: P1

(7)Adjust the secondary timing before adjusting the governor.

----------

K=16 BCL=1.3+-0.1mm P1=((392)kPa{(4)kgf/cm2})

----------

----------

K=16 BCL=1.3+-0.1mm P1=((392)kPa{(4)kgf/cm2})

----------

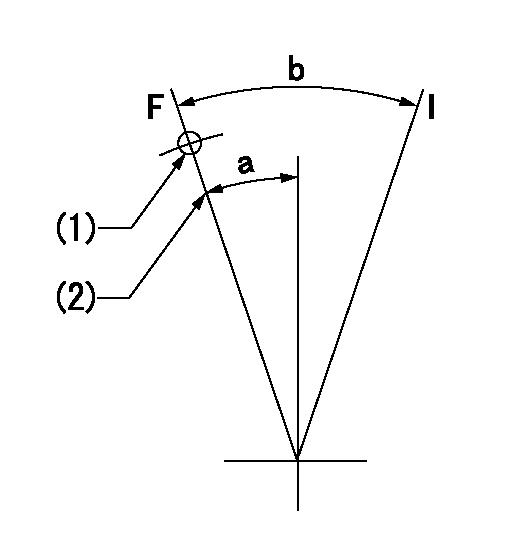

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=74mm

----------

a=20deg+-5deg b=36deg+-5deg

----------

aa=74mm

----------

a=20deg+-5deg b=36deg+-5deg

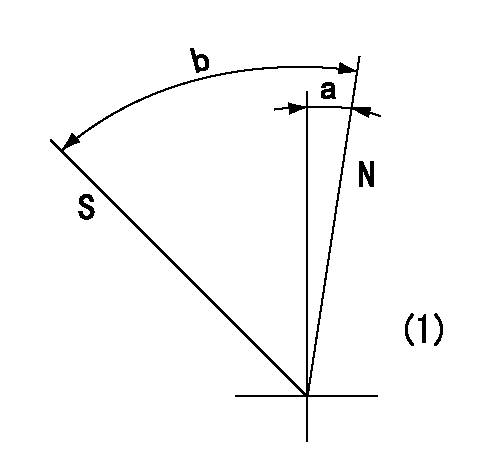

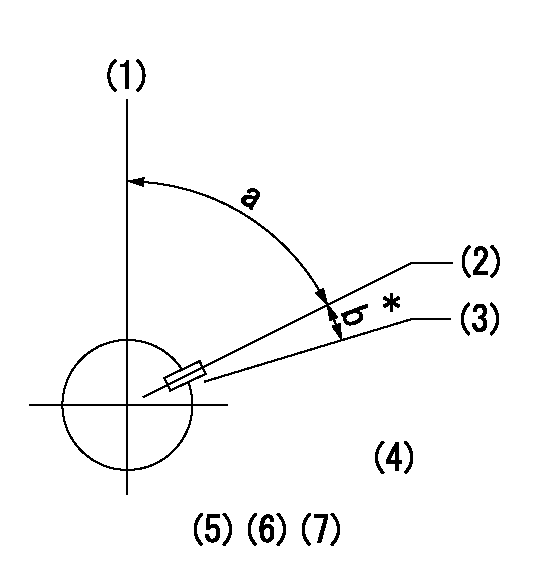

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

----------

----------

a=0deg+-5deg b=53deg+-5deg

----------

----------

a=0deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Key groove position at No. 1 cylinder's beginning of injection position (at BTDC: aa).

(3)Position of the key groove of the No. 1 cylinder at B.T.D.C. bb (fix the governor flyweight at this position for delivery).

(4)B.T.D.C.: aa

(5)At second timing adjustment, set the camshaft at the * position and tighten the flyweight locknut.

(6)Align the flyweight's timing gear position with the lockpin groove and then fully tighten the flyweight to the camshaft.

(7)Remove the lock pin and adjust the governor. Reinstall the lock pin to fix the flyweight for delivery.

----------

aa=15deg bb=0deg

----------

a=54deg54min+-3deg b=7deg30min+-30min

----------

aa=15deg bb=0deg

----------

a=54deg54min+-3deg b=7deg30min+-30min

Information:

Caterpillar Reference Material

SEBD0518, Know Your Cooling SystemSEBD0970, Coolant and Your EngineSEHS7067, Fuels for Caterpillar Diesel EnginesSEHS8622, Using the FT1984 Air-To-Air Aftercooler Leak Test GroupSEHS8741, Using 8C5919 Service Program Module Operating ManualSEHS8743, Using 7X1830 Service Program Module Operating ManualSEHS8746, Using the 1U5540 Tool GroupSEHS8867, Using the 1U6661 Pop (Injector) TesterSEHS8884, Unit Injector Test SpecificationsLEDT5092, Driving Techniques For Maximum Fuel EconomyLEBT8121, Truck Engine Application and Installation GuideLEKQ3363, Caterpillar Engine Data Sheet 60.1 - "Fuels Recommended For Use In Caterpillar Truck Engines"SEBU6310, EMA Engine Oil Data BookSEBD0640, Oil and Your EngineSEBD0717, Diesel Fuels and Your EngineSEHS9031, Storage Procedure for Caterpillar ProductsSEBP1798, 3176 ATAAC Truck Engine Parts Manual (2YG1 and Up)SEBP1799, 3176 ATAAC Truck Engine Parts Manual (2YG1 and Up)SEBP1954, 3176 ATAAC Truck Engine Parts Manual (7LG1 and Up)SENR3910, 3176 ATAAC Truck Engine Service Manual (2YG1 and Up)SENR5105, 3176 ATAAC Truck Engine Service Manual (7LG1 and Up)SENR3912, 3176 ATAAC Truck Engine Schematic Manual (2YG1 and Up)SENR5111, 3176 ATAAC Truck Engine Schematic Manual (7LG1 and Up)SENR3913, 3176 ATAAC Truck Engine Electrical Manual (2YG1 and Up)SENR5112, 3176 ATAAC Truck Engine Electrical Manual (7LG1 and Up)SENR3616, 3176 ATAAC Truck Engine Troubleshooting Manual (2YG1 and Up)SENR5110, 3176 ATAAC Truck Engine Troubleshooting Manual (7LG1 and Up)SENR4248 3176 ATAAC Truck Engine Mechanical Manual (2YG1 and Up)SENR5113 3176 ATAAC Truck Engine Mechanical Manual (7LG1 and Up)SENR4249, 3176 ATAAC Truck Engine Performance Specifications (7LG1 and Up)SENR5114, 3176 ATAAC Truck Engine Performance Specifications (7LG1 and Up)SENR4250, 3176 ATAAC Truck Engine OEM Systems Manual (2YG1 and Up)SENR5115, 3176 ATAAC Truck Engine OEM Systems Manual (7LG1 and Up)SENR4251, 3176 ATAAC Truck Engine Jacobs Brake Manual (2YG1 and Up)SENR5116, 3176 ATAAC Truck Engine Jacobs Brake Manual (7LG1 and Up)SEBR0514, Low Emission systemSEBF8029, Index to Guidelines for Reusable Parts and Salvage OperationsSEBF8062, Guideline for Reusable Parts-Procedure to Inspect and Clean Air FiltersPEHP7504, CAT Engine Oil Spec SheetsPEHP7505, CAT Diesel Engine Oil Spec SheetsAll of the above publications are available through your Caterpillar dealer.Additional Reference Material

ASTM D2896 -TBN MeasurementsASTM D1384 -Glassware Corrosion TestASTM D2809 -Cavitation Corrosion of Aluminum TestASTM D4340 -Hot Surface Corrosion of Aluminum TestASTM Specs can normally be obtained from your local technilogical society, library or college.SAE J313 -Diesel FuelsSAE J754 -NomenclatureSAE J183 -ClassificationSAE Specs can be found in your SAE handbook or can be obtained from your local library, college or technilogical society.

SEBD0518, Know Your Cooling SystemSEBD0970, Coolant and Your EngineSEHS7067, Fuels for Caterpillar Diesel EnginesSEHS8622, Using the FT1984 Air-To-Air Aftercooler Leak Test GroupSEHS8741, Using 8C5919 Service Program Module Operating ManualSEHS8743, Using 7X1830 Service Program Module Operating ManualSEHS8746, Using the 1U5540 Tool GroupSEHS8867, Using the 1U6661 Pop (Injector) TesterSEHS8884, Unit Injector Test SpecificationsLEDT5092, Driving Techniques For Maximum Fuel EconomyLEBT8121, Truck Engine Application and Installation GuideLEKQ3363, Caterpillar Engine Data Sheet 60.1 - "Fuels Recommended For Use In Caterpillar Truck Engines"SEBU6310, EMA Engine Oil Data BookSEBD0640, Oil and Your EngineSEBD0717, Diesel Fuels and Your EngineSEHS9031, Storage Procedure for Caterpillar ProductsSEBP1798, 3176 ATAAC Truck Engine Parts Manual (2YG1 and Up)SEBP1799, 3176 ATAAC Truck Engine Parts Manual (2YG1 and Up)SEBP1954, 3176 ATAAC Truck Engine Parts Manual (7LG1 and Up)SENR3910, 3176 ATAAC Truck Engine Service Manual (2YG1 and Up)SENR5105, 3176 ATAAC Truck Engine Service Manual (7LG1 and Up)SENR3912, 3176 ATAAC Truck Engine Schematic Manual (2YG1 and Up)SENR5111, 3176 ATAAC Truck Engine Schematic Manual (7LG1 and Up)SENR3913, 3176 ATAAC Truck Engine Electrical Manual (2YG1 and Up)SENR5112, 3176 ATAAC Truck Engine Electrical Manual (7LG1 and Up)SENR3616, 3176 ATAAC Truck Engine Troubleshooting Manual (2YG1 and Up)SENR5110, 3176 ATAAC Truck Engine Troubleshooting Manual (7LG1 and Up)SENR4248 3176 ATAAC Truck Engine Mechanical Manual (2YG1 and Up)SENR5113 3176 ATAAC Truck Engine Mechanical Manual (7LG1 and Up)SENR4249, 3176 ATAAC Truck Engine Performance Specifications (7LG1 and Up)SENR5114, 3176 ATAAC Truck Engine Performance Specifications (7LG1 and Up)SENR4250, 3176 ATAAC Truck Engine OEM Systems Manual (2YG1 and Up)SENR5115, 3176 ATAAC Truck Engine OEM Systems Manual (7LG1 and Up)SENR4251, 3176 ATAAC Truck Engine Jacobs Brake Manual (2YG1 and Up)SENR5116, 3176 ATAAC Truck Engine Jacobs Brake Manual (7LG1 and Up)SEBR0514, Low Emission systemSEBF8029, Index to Guidelines for Reusable Parts and Salvage OperationsSEBF8062, Guideline for Reusable Parts-Procedure to Inspect and Clean Air FiltersPEHP7504, CAT Engine Oil Spec SheetsPEHP7505, CAT Diesel Engine Oil Spec SheetsAll of the above publications are available through your Caterpillar dealer.Additional Reference Material

ASTM D2896 -TBN MeasurementsASTM D1384 -Glassware Corrosion TestASTM D2809 -Cavitation Corrosion of Aluminum TestASTM D4340 -Hot Surface Corrosion of Aluminum TestASTM Specs can normally be obtained from your local technilogical society, library or college.SAE J313 -Diesel FuelsSAE J754 -NomenclatureSAE J183 -ClassificationSAE Specs can be found in your SAE handbook or can be obtained from your local library, college or technilogical society.