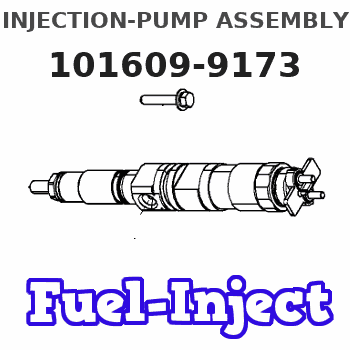

Information injection-pump assembly

BOSCH

9 400 615 919

9400615919

ZEXEL

101609-9173

1016099173

MITSUBISHI-HEAV

3436501011

3436501011

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Aftermarket Fuel Injection Pump 101609-9173 34365-01011 Fit Intended For S4K Engine E200B 312 Excavator

Generic

Generic

Nayuank Fuel Injection Pump 101609-9173 1016099173 Fits For Mitsubishi S4K Fits For Carterpillar CAT Excavator 312 E200B

Nayuank Part Name: Fuel Injection Pump || Part Number: 101609-9173 1016099173 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Engine Model: S4K || Applicable: Fits For Mitsubishi Engine S4K || Fits For Carterpillar CAT Excavator 312 E200B

Nayuank Part Name: Fuel Injection Pump || Part Number: 101609-9173 1016099173 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Engine Model: S4K || Applicable: Fits For Mitsubishi Engine S4K || Fits For Carterpillar CAT Excavator 312 E200B

Nayuank Fuel Injection Pump 101609-9173 34365-01011 Fits For Mitsubishi Engine S4K Fits For Caterpillar CAT Excavator E200B 312

Nayuank Part Name: Fuel Injection Pump || Part Number: 101609-9173 34365-01011 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Engine Model: S4K || Applicable: Fits For Mitsubishi Engine S4K || Fits For Caterpillar CAT Excavator E200B 312

Nayuank Part Name: Fuel Injection Pump || Part Number: 101609-9173 34365-01011 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Engine Model: S4K || Applicable: Fits For Mitsubishi Engine S4K || Fits For Caterpillar CAT Excavator E200B 312

You can express buy:

USD 1224.05

19-05-2025

19-05-2025

XCWoOshop Hydraulic Fuel Injection Pump 101609-9173 for Mitsubishi S4K Engine Carterpillar CAT E200B 312 Excavator

Service parts 101609-9173 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

101609-9173

as INJECTION-PUMP ASSEMBLY

Include in #2:

104015-8180

as _

Cross reference number

Zexel num

Bosch num

Firm num

Name

101609-9173

9 400 615 919

3436501011 MITSUBISHI-HEAV

INJECTION-PUMP ASSEMBLY

S6K-T K 14BF INJECTION PUMP ASSY PE6AD PE

S6K-T K 14BF INJECTION PUMP ASSY PE6AD PE

Information:

Above 32°F (0°C)

Make sure no one is working on or close to the machine before starting the engine. Fasten seat belt.

1. Make certain TRANSMISSION NEUTRAL LOCK and PARKING BRAKE LOCKING lever is engaged. Move all implement controls to HOLD. 2. Insert the key in the disconnect switch and turn the switch ON.

Never turn the disconnect switch OFF with the engine running.

3. Move the governor control lever to the low idle position just past the detent. 4. Push in and turn the START switch to START. Release the switch when the engine starts.Below 32°F (0°C)

1. Follow steps 1-thru-4 for above 32°F (0°C). If engine does not start, push in the Starting Aid Button. A metered amount of starting fluid, sufficient to help start the engine, is released each time the Starting Aid Button is pushed in. 2. While cranking the engine use additional Starting Aid Fluid every 2 seconds, by pushing the button in and releasing it. 3. Release the START switch when the engine starts.4. If necessary continue the use of Starting Aid Fluid every 2 seconds after the engine starts, until it runs smoothly.

After every 30 seconds of cranking, allow 2 minutes for the starting motor to cool.

5. If extra battery capacity is needed, refer to the Operator's Guide SEBU5516 - 955L, 977L & 983B Track Type Loaders.6. Refer to the Operator's Guide for after starting checks, warm up procedure and engine shutdown. For starting below 0°F (-18°C) the use of optional cold weather starting aids is recommended. A coolant heater, jacket water heater or extra battery capacity may be required.

The Starting Aid Ether Bottle must be removed before transporting the machine. See the Lubrication and Maintenance Guide SEBU5515 for removal and replacing the bottle.

Make sure no one is working on or close to the machine before starting the engine. Fasten seat belt.

1. Make certain TRANSMISSION NEUTRAL LOCK and PARKING BRAKE LOCKING lever is engaged. Move all implement controls to HOLD. 2. Insert the key in the disconnect switch and turn the switch ON.

Never turn the disconnect switch OFF with the engine running.

3. Move the governor control lever to the low idle position just past the detent. 4. Push in and turn the START switch to START. Release the switch when the engine starts.Below 32°F (0°C)

1. Follow steps 1-thru-4 for above 32°F (0°C). If engine does not start, push in the Starting Aid Button. A metered amount of starting fluid, sufficient to help start the engine, is released each time the Starting Aid Button is pushed in. 2. While cranking the engine use additional Starting Aid Fluid every 2 seconds, by pushing the button in and releasing it. 3. Release the START switch when the engine starts.4. If necessary continue the use of Starting Aid Fluid every 2 seconds after the engine starts, until it runs smoothly.

After every 30 seconds of cranking, allow 2 minutes for the starting motor to cool.

5. If extra battery capacity is needed, refer to the Operator's Guide SEBU5516 - 955L, 977L & 983B Track Type Loaders.6. Refer to the Operator's Guide for after starting checks, warm up procedure and engine shutdown. For starting below 0°F (-18°C) the use of optional cold weather starting aids is recommended. A coolant heater, jacket water heater or extra battery capacity may be required.

The Starting Aid Ether Bottle must be removed before transporting the machine. See the Lubrication and Maintenance Guide SEBU5515 for removal and replacing the bottle.

Have questions with 101609-9173?

Group cross 101609-9173 ZEXEL

Dpico

Mitsubishi-Heav

Dpico

Mitsubishi-Heav

Mitsubishi-Heav

101609-9173

9 400 615 919

3436501011

INJECTION-PUMP ASSEMBLY

S6K-T

S6K-T