Information injection-pump assembly

BOSCH

9 400 611 221

9400611221

ZEXEL

101405-3190

1014053190

KOMATSU

3863901

3863901

Rating:

Service parts 101405-3190 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Cross reference number

BOSCH

9 400 611 221

9400611221

ZEXEL

101405-3190

1014053190

KOMATSU

3863901

3863901

Zexel num

Bosch num

Firm num

Name

101405-3190

9 400 611 221

3863901 KOMATSU

INJECTION-PUMP ASSEMBLY

S4D102E K

S4D102E K

101405-3190

9 400 611 221

6732711171 KOMATSU

INJECTION-PUMP ASSEMBLY

S4D102E K

S4D102E K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-3420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

2.5

2.45

2.55

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.1

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

78.5

77.5

79.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

9.1+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

23.5

22.5

24.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85

85

95

Fixing the lever

*

Rack limit

*

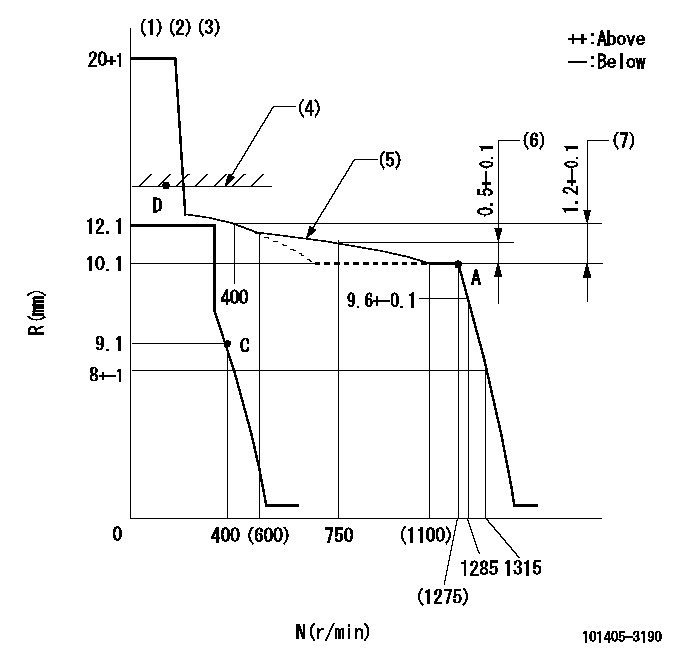

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Adjust the secondary timing before adjusting the governor.

(4)RACK LIMIT

(5)The torque control spring must does not have a set force.

(6)Rack difference between N = N1 and N = N2

(7)Rack difference between N = N3 and N = N4

----------

K=12 N1=1250r/min N2=750r/min N3=1250r/min N4=400r/min

----------

----------

K=12 N1=1250r/min N2=750r/min N3=1250r/min N4=400r/min

----------

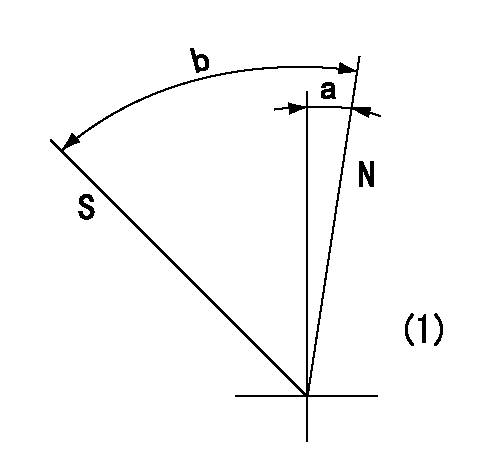

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=14deg+-5deg b=32deg+-5deg

----------

----------

a=14deg+-5deg b=32deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)No return spring

----------

----------

a=0deg+-5deg b=53deg+-5deg

----------

----------

a=0deg+-5deg b=53deg+-5deg

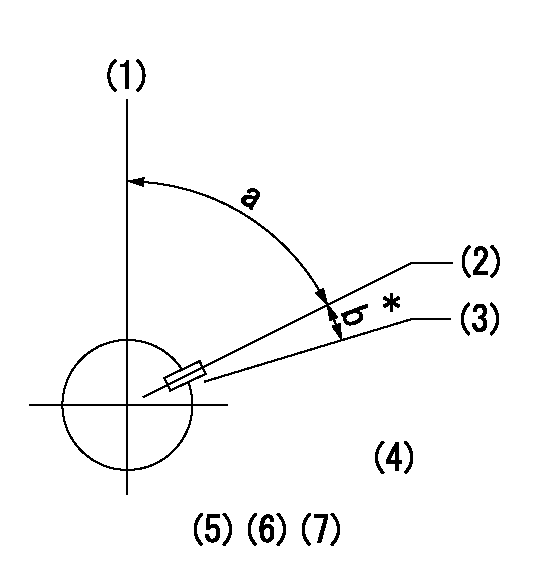

Timing setting

(1)Pump vertical direction

(2)Key groove position at No. 1 cylinder's beginning of injection position (at BTDC: aa).

(3)Position of the key groove of the No. 1 cylinder at B.T.D.C. bb (fix the governor flyweight at this position for delivery).

(4)B.T.D.C.: aa

(5)At second timing adjustment, set the camshaft at the * position and tighten the flyweight locknut.

(6)Align the flyweight's timing gear position with the lockpin groove and then fully tighten the flyweight to the camshaft.

(7)Remove the lock pin and adjust the governor. Reinstall the lock pin to fix the flyweight for delivery.

----------

aa=15.5deg bb=0deg

----------

a=54deg54min+-3deg b=7deg45min+-30min

----------

aa=15.5deg bb=0deg

----------

a=54deg54min+-3deg b=7deg45min+-30min

Information:

Owner Warranty Rights and Obligations

The California Air Resources Board (CARB) and Caterpillar Inc. are pleased to explain the emission control system warranty on your 1991 truck engine.In California, new motor vehicle engines must be designed, built and equipped to meet the state's stringent anti-smog standards. Caterpillar Inc. must warrant the emission control system on your truck engine for the duration of time listed below provided there has not been any abuse, neglect or improper maintenance of your truck engine.Your emission control system may include parts such as the fuel injection system and engine computer, if equipped. Also included may be hoses, connectors, clamps and other emission-related components.Where a warrantable condition exists, Caterpillar Inc. will repair the truck engine at no cost to the owner including diagnosis, parts and labor.Manufacturer's Warranty Coverage

* The emissions warranty period for new truck engines is a duration of 60 months, 100,000 miles (161 000 km), or 3,000 hours of operation, whichever occurs first.* If an emission related part or component on your truck engine is defective, the part or component will be repaired or replaced by Caterpillar Inc. This is your emission control system WARRANTY.Owner's Warranty Responsibilities

* As the truck engine owner, you are responsible for the performance of the required maintenance listed in the truck engine owner's manual (Operation and Maintenance Manual). Caterpillar Inc. recommends that you retain all receipts and records covering the maintenance on your truck engine, but cannot deny warranty solely for the lack of receipts and records or for your failure to ensure the performance of all scheduled maintenance.* You are responsible for presenting your truck engine to a Caterpillar Inc. dealer as soon as a truck engine problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.* As the truck engine owner, you should also be aware that Caterpillar Inc. may deny you warranty coverage if your truck engine or an emission component or part has failed due to abuse, neglect, improper maintenance or unapproved modifications.If you have questions regarding your warranty rights and responsibilities, contact:Caterpillar Inc.

Manager, Truck Engine Business

Peoria, IL 61629

Phone (309) 578-6288

OR

California Air Resources Board (CARB)

9528 Telstar Ave.

El Monte, CA 91731

Emissions Warranty

Caterpillar Inc. warrants to the initial owner and subsequent owner of a diesel truck engine (powering an on-highway truck), that such engine is ...1. Designed, built and equipped so as to conform, at the time of sale, with all applicable regulations adopted by the California Air Resources Board (CARB).2. Free from defects in materials and workmanship in specific emission related parts for a period of 60 months, 100,000 miles (161 000 km) or 3,000 hours of operation, whichever occurs first, after date of delivery to the initial owner.If an emission related part fails during the warranty period, it will be repaired or replaced. Any such part repaired or replaced under warranty is warranted for the remainder of the warranty period.During the term of this warranty, Caterpillar Inc. will provide through a Caterpillar dealer or other

The California Air Resources Board (CARB) and Caterpillar Inc. are pleased to explain the emission control system warranty on your 1991 truck engine.In California, new motor vehicle engines must be designed, built and equipped to meet the state's stringent anti-smog standards. Caterpillar Inc. must warrant the emission control system on your truck engine for the duration of time listed below provided there has not been any abuse, neglect or improper maintenance of your truck engine.Your emission control system may include parts such as the fuel injection system and engine computer, if equipped. Also included may be hoses, connectors, clamps and other emission-related components.Where a warrantable condition exists, Caterpillar Inc. will repair the truck engine at no cost to the owner including diagnosis, parts and labor.Manufacturer's Warranty Coverage

* The emissions warranty period for new truck engines is a duration of 60 months, 100,000 miles (161 000 km), or 3,000 hours of operation, whichever occurs first.* If an emission related part or component on your truck engine is defective, the part or component will be repaired or replaced by Caterpillar Inc. This is your emission control system WARRANTY.Owner's Warranty Responsibilities

* As the truck engine owner, you are responsible for the performance of the required maintenance listed in the truck engine owner's manual (Operation and Maintenance Manual). Caterpillar Inc. recommends that you retain all receipts and records covering the maintenance on your truck engine, but cannot deny warranty solely for the lack of receipts and records or for your failure to ensure the performance of all scheduled maintenance.* You are responsible for presenting your truck engine to a Caterpillar Inc. dealer as soon as a truck engine problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.* As the truck engine owner, you should also be aware that Caterpillar Inc. may deny you warranty coverage if your truck engine or an emission component or part has failed due to abuse, neglect, improper maintenance or unapproved modifications.If you have questions regarding your warranty rights and responsibilities, contact:Caterpillar Inc.

Manager, Truck Engine Business

Peoria, IL 61629

Phone (309) 578-6288

OR

California Air Resources Board (CARB)

9528 Telstar Ave.

El Monte, CA 91731

Emissions Warranty

Caterpillar Inc. warrants to the initial owner and subsequent owner of a diesel truck engine (powering an on-highway truck), that such engine is ...1. Designed, built and equipped so as to conform, at the time of sale, with all applicable regulations adopted by the California Air Resources Board (CARB).2. Free from defects in materials and workmanship in specific emission related parts for a period of 60 months, 100,000 miles (161 000 km) or 3,000 hours of operation, whichever occurs first, after date of delivery to the initial owner.If an emission related part fails during the warranty period, it will be repaired or replaced. Any such part repaired or replaced under warranty is warranted for the remainder of the warranty period.During the term of this warranty, Caterpillar Inc. will provide through a Caterpillar dealer or other

Have questions with 101405-3190?

Group cross 101405-3190 ZEXEL

Komatsu

Komatsu

101405-3190

9 400 611 221

3863901

INJECTION-PUMP ASSEMBLY

S4D102E

S4D102E

101405-3190

9 400 611 221

6732711171

INJECTION-PUMP ASSEMBLY

S4D102E

S4D102E