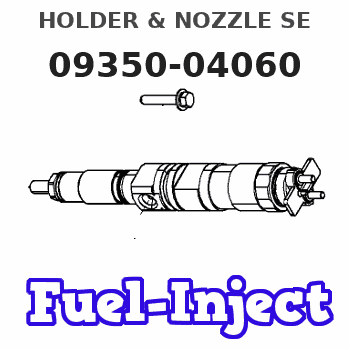

Information holder & nozzle se

Rating:

Components :

| 001. | HOLDER & NOZZLE SE | 09350-04060 |

Scheme ###:

| 000. | [01] | 09350-04062 | HOLDER & NOZZLE SE | |

| 001. | [01] | 09310-04062 | HOLDER ASSY, NOZZL | |

| 001-001. | [01] | 09311-04061 | BODY SUB-ASSY, NOZ | |

| 001-002. | [01] | 09312-10480 | PIN, NOZZLE HOLDER | |

| 001-003. | [01] | 09312-70410 | SPRING, NOZZLE HOL | |

| 001-004. | [01] | 09316-41020 | NUT, NOZZLE RETAIN | |

| 001-005. | [1C] | 09317-52570 | WASHER | |

| 001-005. | [1C] | 09317-52560 | WASHER | |

| 001-005. | [1C] | 09317-52530 | WASHER | |

| 001-005. | [1C] | 09317-52460 | WASHER | |

| 001-005. | [1C] | 09317-52450 | WASHER | |

| 001-005. | [1C] | 09317-52440 | WASHER | |

| 001-005. | [1C] | 09317-52430 | WASHER | |

| 001-005. | [1C] | 09317-52580 | WASHER | |

| 001-005. | [1C] | 09317-52590 | WASHER | |

| 001-005. | [1C] | 09317-52600 | WASHER | |

| 001-005. | [1C] | 09317-52610 | WASHER | |

| 001-005. | [1C] | 09317-52620 | WASHER | |

| 001-005. | [1C] | 09317-52630 | WASHER | |

| 001-005. | [1C] | 09317-52640 | WASHER | |

| 001-005. | [1C] | 09317-52650 | WASHER | |

| 001-005. | [1C] | 09317-52660 | WASHER | |

| 001-005. | [1C] | 09317-52420 | WASHER | |

| 001-005. | [1C] | 09317-52340 | WASHER | |

| 001-005. | [1C] | 09317-52180 | WASHER | |

| 001-005. | [1C] | 09317-52190 | WASHER | |

| 001-005. | [1C] | 09317-52200 | WASHER | |

| 001-005. | [1C] | 09317-52210 | WASHER | |

| 001-005. | [1C] | 09317-52220 | WASHER | |

| 001-005. | [1C] | 09317-52230 | WASHER | |

| 001-005. | [1C] | 09317-52240 | WASHER | |

| 001-005. | [1C] | 09317-52250 | WASHER | |

| 001-005. | [1C] | 09317-52260 | WASHER | |

| 001-005. | [1C] | 09317-52330 | WASHER | |

| 001-005. | [1C] | 09317-52320 | WASHER | |

| 001-005. | [1C] | 09317-52310 | WASHER | |

| 001-005. | [1C] | 09317-52300 | WASHER | |

| 001-005. | [1C] | 09317-52290 | WASHER | |

| 001-005. | [1C] | 09317-52280 | WASHER | |

| 001-005. | [1C] | 09317-52270 | WASHER | |

| 001-006. | [01] | 09322-10150 | PACKING, TIP | |

| 001-007. | [02] | 94908-23160 | PIN, STRAIGHT | |

| 001-008. | [01] | 09316-60080 | SCREW, HOLLOW | |

| 001-009. | [02] | 94901-81020 | WASHER, COPPER PLA | S2286-71500-A |

| 002. | [01] | 09340-05590 | NOZZLE ASSY |

Include as Nozzle:

0960004600

as Nozzle

Cross reference number

| Part num | Firm num | Firm | Name |

| 09350-04060 | HOLDER & NOZZLE SE | ||

| 23600-58031-000 | DAIHATSU | HOLDER & NOZZLE SE | |

| 23600-58031 | TOYOTA | HOLDER & NOZZLE SE |

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

DEF injector failures are occurring at early hours on I6 engine products leading to fault codes and inducements which causes customer downtime. Failed part returns indicate that a portion of the injectors is no fault found when tested at Caterpillar®. Caterpillar® is investigating the root cause of these injector replacements and to support the investigation is requesting that the following procedure is completed, documented, and sent to Caterpillar®.Solution

Complete the steps listed below and ensure that all DEF Quality, Injector Resistance and Dosing Accuracy Test are completed when requested by the associated troubleshooting guides. Once troubleshooting is completed, submit all information to the following email address: Blunier_Derek_W

Download Product Status Report including all ECMs and histograms.

Download Warranty Report from the engine ECM and aftertreatment ECM.

Illustration 1 g06067373

DEF Injector

Take a picture of the DEF injector part number and serial number as shown in Illustration 1.

Table 1

Media References

Engine Description Media Number

C9.3 Troubleshooting UENR0978

Testing and Adjusting UENR3402

Disassembly / Assembly UENR0130

C13 Troubleshooting UENR0955

Testing and Adjusting UENR4302

Disassembly / Assembly UENR0131

C15 / C18 Troubleshooting UENR0955

Testing and Adjusting UENR3351

Disassembly / Assembly UENR0132

Follow the correct troubleshooting procedure from Table 1 for each corresponding code. For troubleshooting C9.3 use , UENR0978 and for C13, C15, C18 engines use , UENR0955.

Table 2

DEF Quality Results

Step Instruction Completed

(Yes/No) Result

Comments Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test (include photo of test strip if possible) Pass/Fail

3 DEF Concentration Test % @ 20C

Table 3

Injector Resistance Measurement

Step Instruction Completed

(Yes/No) Results

Comments Units

1 Turn the keyswitch to the OFF position. Allow 2 minutes to elapse before proceeding.

2 Disconnect the DEF injector from the applicable harness.

3 Inspect the connector for damage or debris (if damaged take photo)

4 Measure the temperature of the injector (aluminum body) C

5 Connect two 398-4987 connectors to the DEF injector. The connectors must be used to prevent damage to the DEF injector connector.

6 Measure the resistance of the DEF injector. Ohms

Table 4

Dosing Accuracy Test

Step Instruction Completed

(Yes/No) Results

Comments Units

1 Follow the Testing and Adjusting, Aftertreatment SCR System Dosing - Test.

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

DEF injector failures are occurring at early hours on I6 engine products leading to fault codes and inducements which causes customer downtime. Failed part returns indicate that a portion of the injectors is no fault found when tested at Caterpillar®. Caterpillar® is investigating the root cause of these injector replacements and to support the investigation is requesting that the following procedure is completed, documented, and sent to Caterpillar®.Solution

Complete the steps listed below and ensure that all DEF Quality, Injector Resistance and Dosing Accuracy Test are completed when requested by the associated troubleshooting guides. Once troubleshooting is completed, submit all information to the following email address: Blunier_Derek_W

Download Product Status Report including all ECMs and histograms.

Download Warranty Report from the engine ECM and aftertreatment ECM.

Illustration 1 g06067373

DEF Injector

Take a picture of the DEF injector part number and serial number as shown in Illustration 1.

Table 1

Media References

Engine Description Media Number

C9.3 Troubleshooting UENR0978

Testing and Adjusting UENR3402

Disassembly / Assembly UENR0130

C13 Troubleshooting UENR0955

Testing and Adjusting UENR4302

Disassembly / Assembly UENR0131

C15 / C18 Troubleshooting UENR0955

Testing and Adjusting UENR3351

Disassembly / Assembly UENR0132

Follow the correct troubleshooting procedure from Table 1 for each corresponding code. For troubleshooting C9.3 use , UENR0978 and for C13, C15, C18 engines use , UENR0955.

Table 2

DEF Quality Results

Step Instruction Completed

(Yes/No) Result

Comments Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test (include photo of test strip if possible) Pass/Fail

3 DEF Concentration Test % @ 20C

Table 3

Injector Resistance Measurement

Step Instruction Completed

(Yes/No) Results

Comments Units

1 Turn the keyswitch to the OFF position. Allow 2 minutes to elapse before proceeding.

2 Disconnect the DEF injector from the applicable harness.

3 Inspect the connector for damage or debris (if damaged take photo)

4 Measure the temperature of the injector (aluminum body) C

5 Connect two 398-4987 connectors to the DEF injector. The connectors must be used to prevent damage to the DEF injector connector.

6 Measure the resistance of the DEF injector. Ohms

Table 4

Dosing Accuracy Test

Step Instruction Completed

(Yes/No) Results

Comments Units

1 Follow the Testing and Adjusting, Aftertreatment SCR System Dosing - Test.