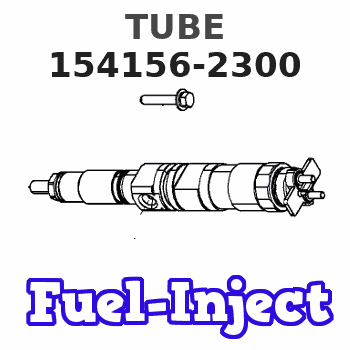

Information tube

BOSCH

9 421 612 044

9421612044

ZEXEL

154156-2300

1541562300

ISUZU

1157792090

1157792090

Rating:

Include in ###:

Cross reference number

Zexel num

Bosch num

Firm num

Name

154156-2300

9 421 612 044

1157792090 ISUZU

TUBE

C 14GJ TUBE GOV

C 14GJ TUBE GOV

154156-2300

9 421 612 044

223414480A HINO

TUBE

C 14GJ TUBE GOV

C 14GJ TUBE GOV

154156-2300

9 421 612 044

ME726106 MITSUBISHI

TUBE

C 14GJ TUBE GOV

C 14GJ TUBE GOV

154156-2300

9 421 612 044

19232Z9005 NISSAN-DIESEL

TUBE

C 14GJ TUBE GOV

C 14GJ TUBE GOV

Information:

Disassembly and Reassembly of General Parts

Oil seals

When driving oil seals into place, follow the instructions below: Driving Seals into Housing:(a) Place the seal lip correctly. Make sure it is not damaged.(b) Before driving a seal into place, apply a light coat of grease to the periphery of the seal that fits into the housing.(c) Use a driving tool like the one shown in the illustration that is specifically designed for the purpose. The tool can properly guide the lip and hold evenly the top of the seal when it is tapped, so it allows the seal to be driven straight down. Do not use hammers on bare seals as seal will be damaged.

Oil seal driving tool Driving Seals onto Shaft:(a) Coat the seal lip with grease.(b) Use seal guide like the one shown in the illustration when the shaft has steps, splines, threads or keyways.

Oil seal guideO-Rings

Use a guide when it is necessary to move O-rings over steps, splines, threads or keyways to install them. Apply a light coat of grease to O-rings before fitting them.

O-ring guideBearings

(1) When driving bearing into place, be sure to tap the race that is being fitted. (If the inner race is being fitted, tap the inner race. Likewise, if it is the outer race that is being fitted, tap the outer race.)Use fitting tools like the ones in the illustration that are appropriate for inner or outer races.

Bearing fitting tool(2) Bearings are best fitted using a press as shock loads and errors can be minimized.

Fitting bearing using a pressLock Plates

Always bend lock plates properly. The illustration on the right show some of typical lock plates being bent properly and improperly.

Typical lock plates with good and bad bendsSplit Pins and Spring Pins

As a rule, all split pins must be replaced with new ones after each removal. It is also important to bend split pins properly. Spring pins must be driven into place completely.

Oil seals

When driving oil seals into place, follow the instructions below: Driving Seals into Housing:(a) Place the seal lip correctly. Make sure it is not damaged.(b) Before driving a seal into place, apply a light coat of grease to the periphery of the seal that fits into the housing.(c) Use a driving tool like the one shown in the illustration that is specifically designed for the purpose. The tool can properly guide the lip and hold evenly the top of the seal when it is tapped, so it allows the seal to be driven straight down. Do not use hammers on bare seals as seal will be damaged.

Oil seal driving tool Driving Seals onto Shaft:(a) Coat the seal lip with grease.(b) Use seal guide like the one shown in the illustration when the shaft has steps, splines, threads or keyways.

Oil seal guideO-Rings

Use a guide when it is necessary to move O-rings over steps, splines, threads or keyways to install them. Apply a light coat of grease to O-rings before fitting them.

O-ring guideBearings

(1) When driving bearing into place, be sure to tap the race that is being fitted. (If the inner race is being fitted, tap the inner race. Likewise, if it is the outer race that is being fitted, tap the outer race.)Use fitting tools like the ones in the illustration that are appropriate for inner or outer races.

Bearing fitting tool(2) Bearings are best fitted using a press as shock loads and errors can be minimized.

Fitting bearing using a pressLock Plates

Always bend lock plates properly. The illustration on the right show some of typical lock plates being bent properly and improperly.

Typical lock plates with good and bad bendsSplit Pins and Spring Pins

As a rule, all split pins must be replaced with new ones after each removal. It is also important to bend split pins properly. Spring pins must be driven into place completely.

Have questions with 154156-2300?

Group cross 154156-2300 ZEXEL

Isuzu

154156-2300

9 421 612 044

1157792090

TUBE

Hino

154156-2300

9 421 612 044

223414480A

TUBE

Mitsubishi

154156-2300

9 421 612 044

ME726106

TUBE

Nissan-Diesel

154156-2300

9 421 612 044

19232Z9005

TUBE