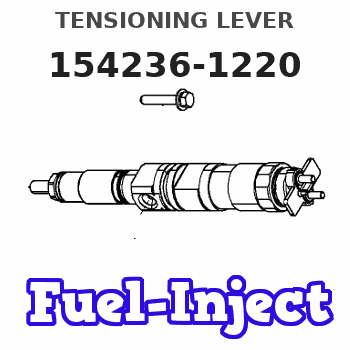

Information tensioning lever

BOSCH

9 421 612 368

9421612368

ZEXEL

154236-1220

1542361220

ISUZU

1157250840

1157250840

Rating:

Include in ###:

Cross reference number

Zexel num

Bosch num

Firm num

Name

154236-1220

9 421 612 368

1157250840 ISUZU

TENSIONING LEVER

C 14GJ TENSION LEVER GOV

C 14GJ TENSION LEVER GOV

154236-1220

9 421 612 368

6059130300 HINO

TENSIONING LEVER

C 14GJ TENSION LEVER GOV

C 14GJ TENSION LEVER GOV

154236-1220

9 421 612 368

223081180A HINO

TENSIONING LEVER

A C 14GJ TENSION LEVER GOV

A C 14GJ TENSION LEVER GOV

154236-1220

9 421 612 368

ME704788 MITSUBISHI

TENSIONING LEVER

C 14GJ TENSION LEVER GOV

C 14GJ TENSION LEVER GOV

154236-1220

9 421 612 368

1933795000 NISSAN-DIESEL

TENSIONING LEVER

C 14GJ TENSION LEVER GOV

C 14GJ TENSION LEVER GOV

Information:

1. Fasten straps and a hoist to the turbocharger.2. Disconnect tube assemblies (1) and (4) from the turbocharger cartridge assembly.3. Remove four bolts (3) and then remove turbocharger (2). Weight of the turbocharger is 23 kg (51 lb.). The following steps are for the installation of the turbocharger.4. Put turbocharger (2) in position with bolts (3).5. Connect tube assemblies (1) and (4) to the turbocharger cartridge assembly.Disassemble Turbocharger

Start By:a. remove turbocharger 1. Install the turbocharger in tool group (A). Put alignment marks on the three housings of the turbocharger for correct installation and alignment at assembly. Remove "V" clamp (2) and compressor housing (1). 2. Remove "V" clamp (3). Remove cartridge housing (5) from turbine housing (4).

When the nut is loosened, do not put a side force on the shaft. This can result in a bent shaft.

3. Install tool (C) in tool (B), and put the cartridge assembly in tool (C) as shown. Use tool (D) to remove the nut that holds compressor wheel (6). 4. Put the cartridge assembly in tool (E), and use a press (if necessary) to remove compressor wheel (6) from the turbine wheel and shaft assembly. Do not let the turbine wheel and shaft assembly fall during removal of the compressor wheel from the turbine wheel and shaft. 5. Remove seal ring (7) and shroud (8) from turbine wheel and shaft assembly (9). 6. Bend the tabs of the locks from bolts (10), and remove the bolts and locks.7. Remove backplate assembly (11) from the cartridge housing. 8. Remove spacer (12) from backplate assembly (11). Remove seal rings (13) from spacer (12). 9. Remove collar (14), thrust bearing (15) and O-ring seal (16) from the cartridge housing. 10. Remove top bearing (17) and the washer from the cartridge housing. Put a long dye mark on the top face of bearing (17).11. Use tool (F), and remove the two rings that hold the top and bottom bearings in position. Remove the bottom bearings and washer. Put a short dye mark on the bearing. The dye marks are used for identification of the bearings when they are installed.12. Use tool (F), and remove the last ring that holds the bottom bearing in position from the cartridge housing.13. Check all the parts of the turbocharger for damage. If the parts are damaged, use new parts for replacement. See Special Instruction Form No. SMHS6854 for Turbocharger Reconditioning. Also see Guidelines For Reusable Parts, Form No. SEBF8018.Assemble Turbocharger

1. Make sure that all of the oil passages in the turbocharger cartridge housing are clean and free of dirt and foreign material.2. Put clean engine oil on all parts of the cartridge assembly.

Rings (18), (21) and (22) must be installed with the round edge of the outside diameter of the rings toward the bearings.

3. Install ring (21) in the cartridge housing with tool (F).4. Install washer (19) and bearing (20) in the cartridge housing. Make sure the short dye mark on bearing (20) is up. 5. Install rings (18) and

Start By:a. remove turbocharger 1. Install the turbocharger in tool group (A). Put alignment marks on the three housings of the turbocharger for correct installation and alignment at assembly. Remove "V" clamp (2) and compressor housing (1). 2. Remove "V" clamp (3). Remove cartridge housing (5) from turbine housing (4).

When the nut is loosened, do not put a side force on the shaft. This can result in a bent shaft.

3. Install tool (C) in tool (B), and put the cartridge assembly in tool (C) as shown. Use tool (D) to remove the nut that holds compressor wheel (6). 4. Put the cartridge assembly in tool (E), and use a press (if necessary) to remove compressor wheel (6) from the turbine wheel and shaft assembly. Do not let the turbine wheel and shaft assembly fall during removal of the compressor wheel from the turbine wheel and shaft. 5. Remove seal ring (7) and shroud (8) from turbine wheel and shaft assembly (9). 6. Bend the tabs of the locks from bolts (10), and remove the bolts and locks.7. Remove backplate assembly (11) from the cartridge housing. 8. Remove spacer (12) from backplate assembly (11). Remove seal rings (13) from spacer (12). 9. Remove collar (14), thrust bearing (15) and O-ring seal (16) from the cartridge housing. 10. Remove top bearing (17) and the washer from the cartridge housing. Put a long dye mark on the top face of bearing (17).11. Use tool (F), and remove the two rings that hold the top and bottom bearings in position. Remove the bottom bearings and washer. Put a short dye mark on the bearing. The dye marks are used for identification of the bearings when they are installed.12. Use tool (F), and remove the last ring that holds the bottom bearing in position from the cartridge housing.13. Check all the parts of the turbocharger for damage. If the parts are damaged, use new parts for replacement. See Special Instruction Form No. SMHS6854 for Turbocharger Reconditioning. Also see Guidelines For Reusable Parts, Form No. SEBF8018.Assemble Turbocharger

1. Make sure that all of the oil passages in the turbocharger cartridge housing are clean and free of dirt and foreign material.2. Put clean engine oil on all parts of the cartridge assembly.

Rings (18), (21) and (22) must be installed with the round edge of the outside diameter of the rings toward the bearings.

3. Install ring (21) in the cartridge housing with tool (F).4. Install washer (19) and bearing (20) in the cartridge housing. Make sure the short dye mark on bearing (20) is up. 5. Install rings (18) and

Have questions with 154236-1220?

Group cross 154236-1220 ZEXEL

Isuzu

154236-1220

9 421 612 368

1157250840

TENSIONING LEVER

Hino

154236-1220

9 421 612 368

6059130300

TENSIONING LEVER

154236-1220

9 421 612 368

223081180A

TENSIONING LEVER

Mitsubishi

154236-1220

9 421 612 368

ME704788

TENSIONING LEVER

Nissan-Diesel

154236-1220

9 421 612 368

1933795000

TENSIONING LEVER