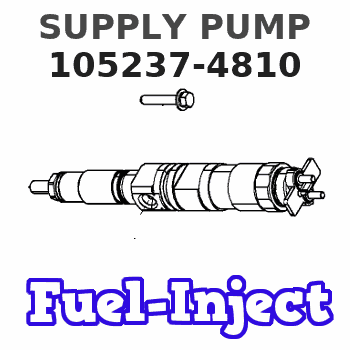

Information supply pump

BOSCH

9 440 610 191

9440610191

ZEXEL

105237-4810

1052374810

MITSUBISHI

ME740007

me740007

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Feed Pump ME731633 ME740007 For Mitsubishi Engine 8DC11 6D40T1 New Aftermarket Parts

YYBMBFBYQ Package included:Fuel Feed Pump*1 || Feature: Stable characteristics, high reliability. || We offer free repair or return or exchange service in the warranty. || Tips: Please check the old part number or the model of the applicable machine before purchasing! || Warm reminder: We will provide comprehensive after-sales service and technical support to ensure that any issues encountered during use can be resolved promptly. Thank you.

YYBMBFBYQ Package included:Fuel Feed Pump*1 || Feature: Stable characteristics, high reliability. || We offer free repair or return or exchange service in the warranty. || Tips: Please check the old part number or the model of the applicable machine before purchasing! || Warm reminder: We will provide comprehensive after-sales service and technical support to ensure that any issues encountered during use can be resolved promptly. Thank you.

AXVEFHXB Compatible Fuel Pump Compatible with 8DC11 6D40T1 Engine Replacement Part 1052374810 ME731633

AXVEFHXB Compatible with 8DC11 and 6D40T1 engines, ensuring integration and performance. || Designed Compatible With Zexel models, this fuel pump meets OEM specifications Compatible With reliability and durability. || Enhances fuel delivery efficiency, contributing to improved engine performance and responsiveness. || Supports a wide usage range in heavy-duty trucking applications, making it ideal Compatible With various vehicles. || Replacement part numbers include 105237-4810 and ME731633 Compatible With easy identification and installation. || Constructed with materials to withstand demanding conditions and extend service life. || Suitable Compatible With both professional mechanics and DIY enthusiasts, simplifying maintenance and repairs.

AXVEFHXB Compatible with 8DC11 and 6D40T1 engines, ensuring integration and performance. || Designed Compatible With Zexel models, this fuel pump meets OEM specifications Compatible With reliability and durability. || Enhances fuel delivery efficiency, contributing to improved engine performance and responsiveness. || Supports a wide usage range in heavy-duty trucking applications, making it ideal Compatible With various vehicles. || Replacement part numbers include 105237-4810 and ME731633 Compatible With easy identification and installation. || Constructed with materials to withstand demanding conditions and extend service life. || Suitable Compatible With both professional mechanics and DIY enthusiasts, simplifying maintenance and repairs.

Fuel Feed Pump 105237-4810 1052374810 For Mitsubishi Engine 8DC11 6D40T1 New Aftermarket Parts

YYBMBFBYQ Package included:Fuel Feed Pump *1 || Feature: Stable characteristics, high reliability. || We offer free repair or return or exchange service in the warranty. || Tips: Please check the old part number or the model of the || Warm reminder: We will provide comprehensive after-sales service and technical support to ensure that any issues encountered during use can be resolved promptly. Thank you.

YYBMBFBYQ Package included:Fuel Feed Pump *1 || Feature: Stable characteristics, high reliability. || We offer free repair or return or exchange service in the warranty. || Tips: Please check the old part number or the model of the || Warm reminder: We will provide comprehensive after-sales service and technical support to ensure that any issues encountered during use can be resolved promptly. Thank you.

You can express buy:

Scheme ###:

| 1. | [1] | 152004-3320 | PUMP HOUSING |

| 5. | [1] | 152100-1120 | PUMP PLUNGER |

| 6. | [1] | 152102-0400 | COMPRESSION SPRING |

| 7. | [1] | 152105-1500 | CAPSULE |

| 8. | [1] | 029332-6030 | GASKET |

| 10. | [1] | 152111-4520 | TAPPET |

| 10/2. | [1] | 152112-0900 | ROLLER |

| 10/3. | [1] | 152113-1300 | BEARING PIN |

| 10/4. | [2] | 152114-1600 | SLIDER |

| 14. | [4] | 152115-0500 | VALVE BODY |

| 14. | [4] | 152115-0500 | VALVE BODY |

| 14. | [4] | 152115-0500 | VALVE BODY |

| 15. | [4] | 152116-0200 | COILED SPRING |

| 15. | [4] | 152116-0200 | COILED SPRING |

| 15. | [4] | 152116-0200 | COILED SPRING |

| 16. | [2] | 152117-0400 | CAPSULE |

| 17. | [1] | 152118-1600 | ADAPTOR |

| 18. | [3] | 029331-6030 | GASKET |

| 18. | [3] | 029331-6030 | GASKET |

| 19. | [1] | 029631-6060 | O-RING |

| 20. | [1] | 152121-0400 | LOCKING WASHER |

| 25. | [1] | 152200-6720 | HAND PRIMER |

| 30. | [1] | 152300-7120 | EYE BOLT |

| 35. | [2] | 029341-4130 | GASKET D20&13.8T2* |

| 49. | [1] | 029731-4570 | EYE BOLT |

| 51. | [2] | 029341-4130 | GASKET D20&13.8T2* |

Include in #1:

108822-2061

as SUPPLY PUMP

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Do not put oil on the bearings until the bearing clearance has been checked.1. Install bearings (1) in the connecting rods they were removed from. Make sure the tab in each bearing is in alignment with the notch in each connecting rod.2. Install bearings (2) in the cylinder block. Make sure the tab in each bearing is in alignment with the notch in the cylinder block. 3. Install pin (3) in the end of the crankshaft. Install the pin so that it extends a maximum of 6.4 mm (.252 in) above the surface. 4. Install the dowel in the crankshaft that puts gear (4) in the correct position. Install the dowel so that it extends 4.1 0.5 mm (.161 .020 in) above the surface of the crankshaft.5. Heat gear (4) to a maximum temperature of 233° C (451° F). Gear (4) must be installed on the crankshaft with the "V" timing mark toward the outside.6. Install gear (4) on the crankshaft. Make sure the notch in the gear is in alignment with the dowel on the crankshaft. The dimension from the rear face of the gear to the front face of the crankshaft must be 45.54 0.25 mm (1.793 .010 in). 7. Fasten Tooling (A) and a hoist to the crankshaft (5) as shown. Install the crankshaft in the engine. The weight of the crankshaft is approximately 131 kg (290 lb). 8. Make sure that "V" mark (6) on the crankshaft is in alignment with "V" mark (7) on the idler gear. The side of each thrust plate (8) with the words "BLOCK SIDE" must be installed with this side toward the cylinder block.9. Put clean oil on thrust plates (8). Install thrust plates (8) next to the center main bearings. Do not put oil on bearings (9) until the bearing clearances have been checked.10. Put bearings (9) in their original position in crankshaft main bearing caps (10).11. Check the crankshaft main bearing clearance with Plastigage as follows:a. Put a piece of Plastigage between the crankshaft bearing journal surface and bearing (9).b. Install the crankshaft main bearing caps (10) with the arrow on each cap toward the front of cylinder block. Each crankshaft main bearing cap has a number on the bottom surface and must be installed in the same position as the correct number on the left side of the cylinder block.c. Put 2P-2506 Thread Lubricant on the threads of the cap bolts. Install the cap bolts finger tight.d. Tighten the bolts on the tab end of the caps first to a torque of 258 14 N m (190 10 lb ft).e. Tighten the bolts on the other end of the caps to a torque of 258 14 N m (190 10 lb ft).

Do not use an impact wrench to tighten the bolts the additional 120 degrees.

f. Put a mark across the bolt head and cap. Tighten the bolts opposite the tab end of the cap

Do not use an impact wrench to tighten the bolts the additional 120 degrees.

f. Put a mark across the bolt head and cap. Tighten the bolts opposite the tab end of the cap