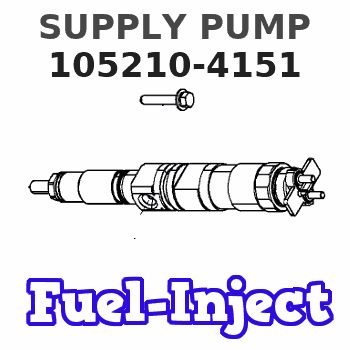

Information supply pump

BOSCH

9 440 610 024

9440610024

ZEXEL

105210-4151

1052104151

MITSUBISHI

ME730589

me730589

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Scheme ###:

| 1. | [1] | 152004-0920 | PUMP HOUSING |

| 5. | [1] | 152100-1120 | PUMP PLUNGER |

| 6. | [1] | 152102-0400 | COMPRESSION SPRING |

| 7. | [1] | 152105-1500 | CAPSULE |

| 8. | [1] | 029332-6030 | GASKET |

| 10. | [1] | 152111-2920 | TAPPET |

| 10/2. | [1] | 152112-1000 | ROLLER |

| 10/3. | [1] | 152113-0100 | BEARING PIN |

| 10/4. | [2] | 152114-0700 | SLIDER |

| 14. | [2] | 152115-0200 | VALVE BODY |

| 14. | [2] | 152115-0200 | VALVE BODY |

| 15. | [2] | 152116-0200 | COILED SPRING |

| 15. | [2] | 152116-0200 | COILED SPRING |

| 16. | [1] | 152117-0100 | CAPSULE |

| 18. | [2] | 029331-6030 | GASKET |

| 18. | [2] | 029331-6030 | GASKET |

| 20. | [1] | 152121-0200 | LOCKING WASHER |

| 25. | [1] | 152200-5620 | HAND PRIMER |

| 30. | [1] | 152300-7120 | EYE BOLT |

| 32. | [1] | 029731-4570 | EYE BOLT |

| 35. | [2] | 029341-4130 | GASKET D20&13.8T2* |

| 36. | [2] | 029341-4130 | GASKET D20&13.8T2* |

Include in #1:

101600-9000

as SUPPLY PUMP

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Daily or every 8 Hours (whichever occurs first)

Check coolant level.Check oil level in sump (make sure machine is standing level).Check oil pressure (where a gauge is fitted).In extreme dust conditions, clean oil bath air cleaner or empty dust bowl on dry type air cleaner.Every 200 Hours or 4 Months (whichever occurs first)

Clean oil bath air cleaner or empty dust bowl on dry type cleaner.Check drive belt tension.Clean fuel water trap (where fitted).Every 400 Hours or 12 Months (whichever occurs first)

Drain and renew engine lubricating oil.Renew lubricating oil filter canister.Renew final fuel filter element.Clean lift pump sediment chamber.Every 800 Hours

Renew dry type air filter element.Every 2,400 Hours

Arrange for examination and service of proprietary equipment, i.e. starter motor, alternator, etc.Service atomisers.Check and adjust valve clearance.Post-Delivery Checkover

After a customer has taken delivery of his Perkins Diesel engine, a general checkover of the engine must be carried out by an experienced fitter after the first 500/1,000 miles (800/1600 km) or 25/50 hours in service with the engine warm.The checkover should comprise the following points:-1. Drain lubricating oil sump and refill to full mark on dipstick with new oil. See list of Approved Lubricating Oils in Appendix. When the sump is drained and it is possible to gain access to the sump strainer, it is recommended that this be cleaned.2. Renew the lubricating oil filter element.3. Remove the rocker assembly; tighten the cylinder head nuts/setscrews in the correct sequence (see Fig. E.12) and to the correct torque (see Page B.2). (Not necessary for 4.2482 The correct procedure for retightening of cylinder head nuts/setscrews is given on Page E.7. Reset valve tip clearances.4. Check coolant level and check for leaks.5. Check external nuts, setscrews, hose clips, mountings etc. for tightness.6. Check fan belt tension.7. Check electrical equipment and connections.8. Check for lubricating oil leaks.9. Check slow running speed (see Page N.9).10. Check general performance of engine. Routine maintenance should follow as detailed under Preventive Maintenance.Protection of an engine not in service

The recommendations given below are to ensure that damage is prevented when an engine is removed from service for an extended period. Use these procedures immediately the engine is removed from service. The instructions for the use of POWERPART products are given on the outside of each container.1. Thoroughly clean the outside of the engine.2. Where a preservative fuel is to be used, drain the fuel system and fill with the preservative fuel. POWERPART Lay-Up 1 can be added to the normal fuel to change it to a preservative fuel. If preservative fuel is not used, the system can be kept charged with normal fuel but this will have to be drained and discarded at the end of the storage period together with the fuel filter.3. Run the engine until it is warm. Correct any fuel, lubricating oil or air leakage. Stop the engine and drain the lubricating oil sump.4. Renew the lubricating oil filter canister.5. Fill the sump to the full mark on the dipstick with clean new lubricating oil or with

Check coolant level.Check oil level in sump (make sure machine is standing level).Check oil pressure (where a gauge is fitted).In extreme dust conditions, clean oil bath air cleaner or empty dust bowl on dry type air cleaner.Every 200 Hours or 4 Months (whichever occurs first)

Clean oil bath air cleaner or empty dust bowl on dry type cleaner.Check drive belt tension.Clean fuel water trap (where fitted).Every 400 Hours or 12 Months (whichever occurs first)

Drain and renew engine lubricating oil.Renew lubricating oil filter canister.Renew final fuel filter element.Clean lift pump sediment chamber.Every 800 Hours

Renew dry type air filter element.Every 2,400 Hours

Arrange for examination and service of proprietary equipment, i.e. starter motor, alternator, etc.Service atomisers.Check and adjust valve clearance.Post-Delivery Checkover

After a customer has taken delivery of his Perkins Diesel engine, a general checkover of the engine must be carried out by an experienced fitter after the first 500/1,000 miles (800/1600 km) or 25/50 hours in service with the engine warm.The checkover should comprise the following points:-1. Drain lubricating oil sump and refill to full mark on dipstick with new oil. See list of Approved Lubricating Oils in Appendix. When the sump is drained and it is possible to gain access to the sump strainer, it is recommended that this be cleaned.2. Renew the lubricating oil filter element.3. Remove the rocker assembly; tighten the cylinder head nuts/setscrews in the correct sequence (see Fig. E.12) and to the correct torque (see Page B.2). (Not necessary for 4.2482 The correct procedure for retightening of cylinder head nuts/setscrews is given on Page E.7. Reset valve tip clearances.4. Check coolant level and check for leaks.5. Check external nuts, setscrews, hose clips, mountings etc. for tightness.6. Check fan belt tension.7. Check electrical equipment and connections.8. Check for lubricating oil leaks.9. Check slow running speed (see Page N.9).10. Check general performance of engine. Routine maintenance should follow as detailed under Preventive Maintenance.Protection of an engine not in service

The recommendations given below are to ensure that damage is prevented when an engine is removed from service for an extended period. Use these procedures immediately the engine is removed from service. The instructions for the use of POWERPART products are given on the outside of each container.1. Thoroughly clean the outside of the engine.2. Where a preservative fuel is to be used, drain the fuel system and fill with the preservative fuel. POWERPART Lay-Up 1 can be added to the normal fuel to change it to a preservative fuel. If preservative fuel is not used, the system can be kept charged with normal fuel but this will have to be drained and discarded at the end of the storage period together with the fuel filter.3. Run the engine until it is warm. Correct any fuel, lubricating oil or air leakage. Stop the engine and drain the lubricating oil sump.4. Renew the lubricating oil filter canister.5. Fill the sump to the full mark on the dipstick with clean new lubricating oil or with