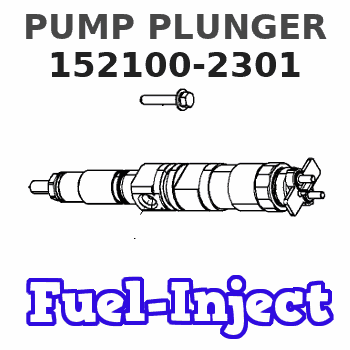

Information pump plunger

BOSCH

9 441 610 179

9441610179

ZEXEL

152100-2301

1521002301

ISUZU

1157520010

1157520010

Rating:

Include in ###:

Cross reference number

Zexel num

Bosch num

Firm num

Name

152100-2301

9 441 610 179

1157520010 ISUZU

PUMP PLUNGER

C 14GD PISTON F/P

C 14GD PISTON F/P

152100-2301

9 441 610 179

225661220A HINO

PUMP PLUNGER

C 14GD PISTON F/P

C 14GD PISTON F/P

152100-2301

9 441 610 179

ME738101 MITSUBISHI

PUMP PLUNGER

C 14GD PISTON F/P

C 14GD PISTON F/P

152100-2301

9 441 610 179

1664589TA2 NISSAN

PUMP PLUNGER

C 14GD PISTON F/P

C 14GD PISTON F/P

152100-2301

9 441 610 179

1664599002 NISSAN-DIESEL

PUMP PLUNGER

C 14GD PISTON F/P

C 14GD PISTON F/P

Information:

A measurement of fuel consumption is used to check fuel system performance. If fuel consumption of an engine is within the tolerance of specifications shown in the Fuel Setting And Related Information Fiche, the fuel system is performing correctly and no additional time should be spent checking fuel delivery.Fuel consumption - If the specified amount of fuel is being injected into the engine, the fuel delivery specification is being met. Therefore, the basic fuel system (fuel pump and lines, transfer pump, filters and primary fuel pressure) is within functional limits. Additional time spent troubleshooting these components is probably not justified.Fuel system timing - Fuel cannot be burned efficiently if it is not injected into the cylinder at the correct time. Because engines only develop horsepower when they are running, timing must be measured when they are running. The pin timing of the engine is not adequate. Timing must be measured throughout the speed range (this also checks the timing advance operation).Intake manifold pressure - Manifold pressure is an indication of the overall health of the engine. Boost is affected by any one or all of the following: fuel consumption, compression (valve condition, piston ring condition), turbocharger performance, intake restriction (air filters), exhaust restriction (muffler) or timing.Recommended Procedure With Chassis Dynamometer

Possible Causes/Corrections 1. Check Records Used To Determine Fuel ConsumptionMake sure the records are accurate. The minimum period for accurate fuel records is one month or 10,000 miles. Check the tires (air pressure and size), the gap between the tractor and trailer, air deflectors, trailer width, trailer type, engine cooling fan and driver habits. See "Owner/Operator Input" section for more information on the questions that should be asked. 2. Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section. 3. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting section of this Service Manual. 4. Check Engine PerformanceDo a Power Analysis Report (PAR), Level II, to check engine performance. Refer to LEBV2810 and SEHS7886 for the tooling and procedures to use. Be sure to make a record of the temperatures for inlet air, fuel (at filter base), lubricating oil and coolant. Also, check for excessive exhaust smoke.At this point, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for the correct procedures to use. Also refer back to the information learned earlier (see "Owner Operator Input" section) about truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic. 5. Worn Fuel NozzlesCheck the horsepower on a dynamometer as in Step 4 above. Make a replacement of the fuel injection nozzles and check the horsepower output again. If there is more than 10 hp difference the old nozzles had eroded orifices and were causing high fuel rate.An alternate test is to lower the fuel setting to get the correct hp output.

Possible Causes/Corrections 1. Check Records Used To Determine Fuel ConsumptionMake sure the records are accurate. The minimum period for accurate fuel records is one month or 10,000 miles. Check the tires (air pressure and size), the gap between the tractor and trailer, air deflectors, trailer width, trailer type, engine cooling fan and driver habits. See "Owner/Operator Input" section for more information on the questions that should be asked. 2. Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section. 3. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting section of this Service Manual. 4. Check Engine PerformanceDo a Power Analysis Report (PAR), Level II, to check engine performance. Refer to LEBV2810 and SEHS7886 for the tooling and procedures to use. Be sure to make a record of the temperatures for inlet air, fuel (at filter base), lubricating oil and coolant. Also, check for excessive exhaust smoke.At this point, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for the correct procedures to use. Also refer back to the information learned earlier (see "Owner Operator Input" section) about truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic. 5. Worn Fuel NozzlesCheck the horsepower on a dynamometer as in Step 4 above. Make a replacement of the fuel injection nozzles and check the horsepower output again. If there is more than 10 hp difference the old nozzles had eroded orifices and were causing high fuel rate.An alternate test is to lower the fuel setting to get the correct hp output.

Have questions with 152100-2301?

Group cross 152100-2301 ZEXEL

Nissan

Nissan-Diesel

Isuzu

152100-2301

9 441 610 179

1157520010

PUMP PLUNGER

Hino

152100-2301

9 441 610 179

225661220A

PUMP PLUNGER

Mitsubishi

152100-2301

9 441 610 179

ME738101

PUMP PLUNGER

Nissan

152100-2301

9 441 610 179

1664589TA2

PUMP PLUNGER

Nissan-Diesel

152100-2301

9 441 610 179

1664599002

PUMP PLUNGER