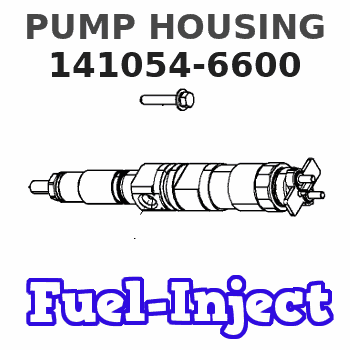

Information pump housing

BOSCH

9 411 619 646

9411619646

ZEXEL

141054-6600

1410546600

ISHIKAWAJIMA

106224

106224

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$63.74

10 Apr 2024

US: Reused Parts LLC

Transfer Case Fits 03-05 Suburban Yukon Tahoe Silverado 1500 Pickup 12579778

Generic Conditions & Options: 12579778, Stock #: KBB728 || Inventory Id: 106224, Mileage: 0 || Designation: Used, Year: 0 || Compatible with Genuine Oem: Yes

Generic Conditions & Options: 12579778, Stock #: KBB728 || Inventory Id: 106224, Mileage: 0 || Designation: Used, Year: 0 || Compatible with Genuine Oem: Yes

$44.00

13 Aug 2024

US: WLSupply

Replacement License Plate Frame Polished - fits 1998-2009 Mercedes-Benz ML320

Sawyer Auto 【❗Vehicle Fitment Details❗:】Fits Mercedes-Benz ML320 1998-2009 || ✅【Enhanced Aesthetics:】The Polished Stainless Steel Finish of This License Plate Frame Adds A Sleek and Stylish Touch To Your 1998-2006 vehicle, Elevating Its Overall Appearance. || ✅【Durable Construction:】Made From Reliable Stainless Steel, This License Plate Frame Offers Excellent Resistance Against Corrosion and Wear, Ensuring Long-Lasting Performance and Protection For Your License Plate. || ✅【Perfect Fit:】Designed Specifically For The 1998-2006 vehicle, This License Plate Frame Guarantees A Precise Fit, Eliminating Any Potential For Loose Or Rattling Plates. || ✅【Product Features:】Finish: Polished | Material: Stainless Steel

Sawyer Auto 【❗Vehicle Fitment Details❗:】Fits Mercedes-Benz ML320 1998-2009 || ✅【Enhanced Aesthetics:】The Polished Stainless Steel Finish of This License Plate Frame Adds A Sleek and Stylish Touch To Your 1998-2006 vehicle, Elevating Its Overall Appearance. || ✅【Durable Construction:】Made From Reliable Stainless Steel, This License Plate Frame Offers Excellent Resistance Against Corrosion and Wear, Ensuring Long-Lasting Performance and Protection For Your License Plate. || ✅【Perfect Fit:】Designed Specifically For The 1998-2006 vehicle, This License Plate Frame Guarantees A Precise Fit, Eliminating Any Potential For Loose Or Rattling Plates. || ✅【Product Features:】Finish: Polished | Material: Stainless Steel

Include in ###:

Cross reference number

Zexel num

Bosch num

Firm num

Name

141054-6600

9 411 619 646

106224 ISHIKAWAJIMA

PUMP HOUSING

A 24XX HOUSING;PUMP PF parts PF

A 24XX HOUSING;PUMP PF parts PF

Information:

Under the Hood Inspection

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn fan belts and trash build-up. Remove trash build-up and have repairs made as needed. * Inspect the radiator for leaks and trash build-up. * Inspect the radiator hoses for cracks and loose clamps.* Inspect the fan and accessory drive belts for cracks, breaks or other damage. Belts for multiple groove pulleys are sold in matched sets. Belts for multiple groove pulleys must be replaced as matched sets. If only one belt of a two or three belt set is replaced, it will carry more of a load than the belts not replaced since the older belts are stretched. The additional load on the new belt could cause it to break. * Inspect the water pump for leaks. The water pump seal is lubricated by coolant in the cooling system. It is normal for a small amount of leakage to occur as the engine cools down and parts contract. * Inspect the engine for oil leaks, such as front and rear crankshaft seals, crankcase, oil filter and valve covers.* Inspect the fuel system for leaks, loose fuel line clamps and fittings and loose or worn hoses. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended service intervals prescribed in this publication until a leak is found or fixed, or until the suspicion for a leak has been proven to be unwarranted. * Inspect wiring for loose connections and worn or frayed wires.* Inspect air intake system hoses and elbows for cracks and loose clamps.* Inspect engine-to-frame ground strap for good connection and condition.Pre-Start Checks

* Measure the engine crankcase oil level. The correct oil level is shown by the marks between the words "ADD" and "FULL RANGE" on the dipstick (oil level gauge) on the "Engine Stopped" side.The location of the ADD and FULL RANGE marks on the engine dipstick are determined by the tilt angle of the engine after it is installed in the truck.If the ADD and FULL RANGE marks have not been stamped on the dipstick, see "Calibration" in the "Dipsticks" section of this manual or contact your authorized Caterpillar dealer. * Check the coolant level with the engine stopped and cold. Remove the filler cap slowly to relieve pressure.* Maintain the coolant level to within 1/2 inch (13 mm) of the bottom of the fill pipe. Install the filler cap.* If equipped with a sight glass, maintain the coolant to the proper level.

To prevent engine damage, never add coolant to an overheated engine. Allow the engine to cool first.

Typical Example* Observe the air cleaner service indicator (if equipped). Service the air cleaner when the yellow diaphragm enters the red zone or the red piston locks in the visible position. If your truck air cleaner is not equipped

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn fan belts and trash build-up. Remove trash build-up and have repairs made as needed. * Inspect the radiator for leaks and trash build-up. * Inspect the radiator hoses for cracks and loose clamps.* Inspect the fan and accessory drive belts for cracks, breaks or other damage. Belts for multiple groove pulleys are sold in matched sets. Belts for multiple groove pulleys must be replaced as matched sets. If only one belt of a two or three belt set is replaced, it will carry more of a load than the belts not replaced since the older belts are stretched. The additional load on the new belt could cause it to break. * Inspect the water pump for leaks. The water pump seal is lubricated by coolant in the cooling system. It is normal for a small amount of leakage to occur as the engine cools down and parts contract. * Inspect the engine for oil leaks, such as front and rear crankshaft seals, crankcase, oil filter and valve covers.* Inspect the fuel system for leaks, loose fuel line clamps and fittings and loose or worn hoses. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended service intervals prescribed in this publication until a leak is found or fixed, or until the suspicion for a leak has been proven to be unwarranted. * Inspect wiring for loose connections and worn or frayed wires.* Inspect air intake system hoses and elbows for cracks and loose clamps.* Inspect engine-to-frame ground strap for good connection and condition.Pre-Start Checks

* Measure the engine crankcase oil level. The correct oil level is shown by the marks between the words "ADD" and "FULL RANGE" on the dipstick (oil level gauge) on the "Engine Stopped" side.The location of the ADD and FULL RANGE marks on the engine dipstick are determined by the tilt angle of the engine after it is installed in the truck.If the ADD and FULL RANGE marks have not been stamped on the dipstick, see "Calibration" in the "Dipsticks" section of this manual or contact your authorized Caterpillar dealer. * Check the coolant level with the engine stopped and cold. Remove the filler cap slowly to relieve pressure.* Maintain the coolant level to within 1/2 inch (13 mm) of the bottom of the fill pipe. Install the filler cap.* If equipped with a sight glass, maintain the coolant to the proper level.

To prevent engine damage, never add coolant to an overheated engine. Allow the engine to cool first.

Typical Example* Observe the air cleaner service indicator (if equipped). Service the air cleaner when the yellow diaphragm enters the red zone or the red piston locks in the visible position. If your truck air cleaner is not equipped

Have questions with 141054-6600?

Group cross 141054-6600 ZEXEL

Ishikawajima

141054-6600

9 411 619 646

106224

PUMP HOUSING