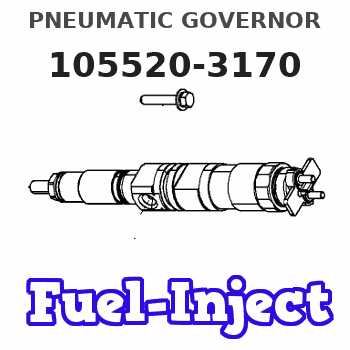

Information pneumatic governor

BOSCH

9 420 610 331

9420610331

ZEXEL

105520-3170

1055203170

NISSAN-DIESEL

19200L2200

19200l2200

Rating:

Scheme ###:

| 1. | [1] | 155000-6720 | GOVERNOR HOUSING |

| 1/1. | [1] | 155001-6120 | GOVERNOR HOUSING |

| 1/2. | [1] | 155003-0600 | CONTROL LEVER |

| 1/3. | [1] | 155004-0900 | LEVER SHAFT |

| 1/4. | [1] | 155005-0200 | COILED SPRING |

| 1/5. | [1] | 155006-0700 | BLEEDER SCREW |

| 1/7. | [1] | 155007-0220 | HEADLESS SCREW |

| 1/8. | [1] | 155011-0200 | HEXAGON NUT |

| 1/9. | [2] | 029010-6010 | CAPSULE |

| 1/9. | [2] | 029010-6010 | CAPSULE |

| 1/10. | [2] | 026506-1040 | GASKET |

| 1/10. | [2] | 026506-1040 | GASKET |

| 1/11. | [0] | 029310-8010 | PLAIN WASHER D15&8.4T0.2 |

| 1/11. | [0] | 029310-8010 | PLAIN WASHER D15&8.4T0.2 |

| 1/11B. | [0] | 029310-8020 | PLAIN WASHER D15&8.4T0.3 |

| 1/12. | [3] | 029010-6680 | BLEEDER SCREW |

| 1/14. | [2] | 029300-8010 | PLAIN WASHER D15&8T1.00 |

| 1/14. | [2] | 029300-8010 | PLAIN WASHER D15&8T1.00 |

| 1/14B. | [0] | 029300-8030 | PLAIN WASHER D15&8T1.50 |

| 1/15. | [2] | 155012-0100 | ADAPTOR |

| 1/15. | [2] | 155012-0100 | ADAPTOR |

| 1/16. | [1] | 155013-0100 | CAP |

| 1/17. | [2] | 029630-8060 | O-RING |

| 1/17. | [2] | 029630-8060 | O-RING |

| 1/18. | [2] | 025520-1210 | SPLIT PIN |

| 2. | [1] | 154007-0200 | ADAPTOR |

| 3. | [1] | 020018-1840 | BLEEDER SCREW |

| 4. | [4] | 021006-1540 | FLAT-HEAD SCREW |

| 5. | [1] | 153406-0400 | BLEEDER SCREW |

| 6. | [1] | 014110-5440 | LOCKING WASHER |

| 7. | [1] | 013020-5220 | UNION NUT M5P0.8H4 |

| 7. | [1] | 013020-5240 | UNION NUT |

| 8. | [1] | 023500-6210 | PLAIN WASHER |

| 9. | [1] | 025520-1210 | SPLIT PIN |

| 10. | [1] | 155020-4320 | DIAPHRAGM |

| 11. | [1] | 155032-7300 | COILED SPRING |

| 12/1. | [0] | 155407-1100 | SHIM D37&30.5T0.5 |

| 12/1. | [0] | 155407-1200 | SHIM D37&30.5T1.0 |

| 12/1. | [0] | 155407-1300 | SHIM D37&30.5T1.5 |

| 12/1. | [0] | 155407-1400 | SHIM D37&30.5T2.0 |

| 12/1. | [0] | 155407-1500 | SHIM D37&30.5T2.5 |

| 12/1. | [0] | 155407-1600 | SHIM D37&30.5T3.0 |

| 12/1. | [0] | 155407-1700 | SHIM D37&30.5T0.2 |

| 12/1. | [0] | 155407-1800 | SHIM D37&30.5T0.3 |

| 13. | [1] | 155240-0500 | COVER |

| 14. | [1] | 155019-0220 | FILLER PIECE |

| 15. | [4] | 020105-1640 | BLEEDER SCREW |

| 18. | [1] | 155241-2220 | HEADLESS SCREW |

| 21. | [1] | 155245-0100 | HEXAGON NUT |

| 23. | [1] | 029142-0010 | CAPSULE |

| 26. | [1] | 029721-2050 | JOINT CONNECTION |

| 27. | [1] | 029721-2040 | JOINT CONNECTION |

| 31. | [1] | 155414-5500 | CONTROL LEVER |

| 40. | [1] | 155404-3700 | CAP |

| 50. | [1] | 014110-8440 | LOCKING WASHER |

| 51. | [1] | 013020-8040 | UNION NUT |

| 100. | [1] | 029621-7010 | PACKING RING |

| 140. | [1] | 154390-0000 | GASKET |

Include in #1:

101331-9140

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

105520-3170

19200L2200 NISSAN-DIESEL

PNEUMATIC GOVERNOR

K 14JQ PNEUMATIC GOVERNOR GOV PG GOV

K 14JQ PNEUMATIC GOVERNOR GOV PG GOV

Information:

Installation of Oil Seal Case

(1) Coat the outside surface of the oil seal with engine oil.(2) Install the oil seal on the oil seal case.(3) Coat the lip of the oil seal with engine oil.(4) Install the O-ring into the oil seal case, and install the oil seal case on the flywheel housing. The oil seal case must be installed with the "Q" mark facing up.(5) Secure the oil seal case with the bolts.

Installation of oil seal caseInstallation of Flywheel

(1) Install the flywheel to the crankshaft by aligning the hole with the dowel pin on the back-end of the crankshaft.(2) Place the washer and tighten the four bolts to the specified torque.

Installation of flywheelMeasurement of Flywheel Axial and Radial Runouts

Measure the flywheel runout with the flywheel installed to the crankshaft. If the standard value is exceeded, check the bolts for tightening condition and the mounting face for adhesion of foreign particles.

Measurement of face runout and circular runoutCylinder Head and Valve Mechanisms

Installation of Valve Stem Seals

(1) Apply engine oil to the valve stem, and insert it into the valve guide.(2) Place a new stem seal on the valve guide.(3) Using the stem seal installer, install the stem seal to the valve guide, making use of the valve stem as a guide.

Installation of valve stem sealInstallation of Valves and Valve Springs

(1) Place the valve spring and retainer on the valve guide, and install the valve cotter using the valve spring pusher.

Excessive compression of the valve spring can cause the retainer to contact the stem seal and damage the seal.

Installation of valve and valve spring(2) Using a soft-faced hammer, tap the top of the valve stem several times to make sure that the spring and valve cotter are securely installed.

Confirmation of secure valve cotter installationInstallation of Cylinder Head Gasket

(1) Make sure that the top face of the crankcase and piston upper surfaces are clean and free of dust.(2) Place a new gasket of the crankcase, making sure that the dowel pins on the top face of the crankcase enter the holes in the gasket.

Do not use a liquid gasket.

Installation of cylinder head gasketInstallation of Cylinder Head

Place the cylinder head on the head gasket, making sure that the dowel pins on the top face of the crankcase enters the holes in the cylinder head.

Installation of cylinder headTightening of Cylinder Head Bolts

Tighten the cylinder head bolts, following the tightening sequence shown in the diagram two or three times before reaching the specified torque.

Cylinder head bolt tightening sequenceAssembly of Rocker Arm and Rocker Shaft Assembly

When installing the rocker arms, make sure that the shaft assembly marks face the front of the engine, as shown in the diagram. After the assembly, make sure that the rocker arms move smoothly.

Assembly of rocker shaft assemblyInstallation of Pushrods

(1) Insert the pushrods in the cylinder head through the pushrod holes.(2) Make sure that the ball end of each pushrod rests securely on the curved surface of the tappet.Installation of Rocker Shaft Assembly

(1) Install the valve caps.(2) Tighten the rocker

(1) Coat the outside surface of the oil seal with engine oil.(2) Install the oil seal on the oil seal case.(3) Coat the lip of the oil seal with engine oil.(4) Install the O-ring into the oil seal case, and install the oil seal case on the flywheel housing. The oil seal case must be installed with the "Q" mark facing up.(5) Secure the oil seal case with the bolts.

Installation of oil seal caseInstallation of Flywheel

(1) Install the flywheel to the crankshaft by aligning the hole with the dowel pin on the back-end of the crankshaft.(2) Place the washer and tighten the four bolts to the specified torque.

Installation of flywheelMeasurement of Flywheel Axial and Radial Runouts

Measure the flywheel runout with the flywheel installed to the crankshaft. If the standard value is exceeded, check the bolts for tightening condition and the mounting face for adhesion of foreign particles.

Measurement of face runout and circular runoutCylinder Head and Valve Mechanisms

Installation of Valve Stem Seals

(1) Apply engine oil to the valve stem, and insert it into the valve guide.(2) Place a new stem seal on the valve guide.(3) Using the stem seal installer, install the stem seal to the valve guide, making use of the valve stem as a guide.

Installation of valve stem sealInstallation of Valves and Valve Springs

(1) Place the valve spring and retainer on the valve guide, and install the valve cotter using the valve spring pusher.

Excessive compression of the valve spring can cause the retainer to contact the stem seal and damage the seal.

Installation of valve and valve spring(2) Using a soft-faced hammer, tap the top of the valve stem several times to make sure that the spring and valve cotter are securely installed.

Confirmation of secure valve cotter installationInstallation of Cylinder Head Gasket

(1) Make sure that the top face of the crankcase and piston upper surfaces are clean and free of dust.(2) Place a new gasket of the crankcase, making sure that the dowel pins on the top face of the crankcase enter the holes in the gasket.

Do not use a liquid gasket.

Installation of cylinder head gasketInstallation of Cylinder Head

Place the cylinder head on the head gasket, making sure that the dowel pins on the top face of the crankcase enters the holes in the cylinder head.

Installation of cylinder headTightening of Cylinder Head Bolts

Tighten the cylinder head bolts, following the tightening sequence shown in the diagram two or three times before reaching the specified torque.

Cylinder head bolt tightening sequenceAssembly of Rocker Arm and Rocker Shaft Assembly

When installing the rocker arms, make sure that the shaft assembly marks face the front of the engine, as shown in the diagram. After the assembly, make sure that the rocker arms move smoothly.

Assembly of rocker shaft assemblyInstallation of Pushrods

(1) Insert the pushrods in the cylinder head through the pushrod holes.(2) Make sure that the ball end of each pushrod rests securely on the curved surface of the tappet.Installation of Rocker Shaft Assembly

(1) Install the valve caps.(2) Tighten the rocker