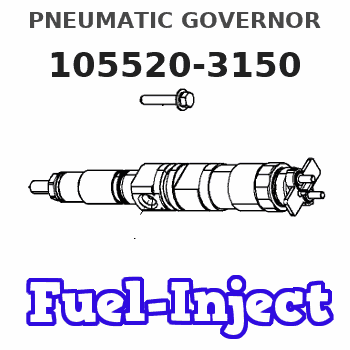

Information pneumatic governor

BOSCH

9 420 610 005

9420610005

ZEXEL

105520-3150

1055203150

NISSAN

19200L2000

19200l2000

Rating:

Scheme ###:

| 1. | [1] | 155000-6720 | GOVERNOR HOUSING |

| 1/1. | [1] | 155001-6120 | GOVERNOR HOUSING |

| 1/2. | [1] | 155003-0600 | CONTROL LEVER |

| 1/3. | [1] | 155004-0900 | LEVER SHAFT |

| 1/4. | [1] | 155005-0200 | COILED SPRING |

| 1/5. | [1] | 155006-0700 | BLEEDER SCREW |

| 1/7. | [1] | 155007-0220 | HEADLESS SCREW |

| 1/8. | [1] | 155011-0200 | HEXAGON NUT |

| 1/9. | [2] | 029010-6010 | CAPSULE M6P1.0L7 |

| 1/9. | [2] | 029010-6010 | CAPSULE M6P1.0L7 |

| 1/10. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 1/10. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 1/11. | [0] | 029310-8010 | PLAIN WASHER D15&8.4T0.2 |

| 1/11B. | [0] | 029310-8020 | PLAIN WASHER D15&8.4T0.3 |

| 1/12. | [3] | 029010-6680 | BLEEDER SCREW |

| 1/14. | [2] | 029300-8010 | PLAIN WASHER D15&8T1.00 |

| 1/14B. | [0] | 029300-8030 | PLAIN WASHER D15&8T1.50 |

| 1/15. | [2] | 155012-0100 | ADAPTOR |

| 1/15. | [2] | 155012-0100 | ADAPTOR |

| 1/16. | [1] | 155013-0100 | CAP |

| 1/17. | [2] | 029630-8060 | O-RING |

| 1/17. | [2] | 029630-8060 | O-RING |

| 1/18. | [2] | 025520-1210 | SPLIT PIN |

| 2. | [1] | 154007-0200 | ADAPTOR |

| 3. | [1] | 020018-1840 | BLEEDER SCREW M8P1.25L18 |

| 4. | [4] | 021006-1540 | FLAT-HEAD SCREW |

| 5. | [1] | 153406-0400 | BLEEDER SCREW |

| 6. | [1] | 014110-5440 | LOCKING WASHER |

| 7. | [0] | 013020-5220 | |

| 7. | [1] | 013020-5240 | UNION NUT M5P0.8H4 |

| 8. | [1] | 023500-6210 | PLAIN WASHER D11&6.4T1.5 |

| 9. | [1] | 025520-1210 | SPLIT PIN |

| 10. | [1] | 155021-5621 | DIAPHRAGM |

| 11. | [1] | 155031-8300 | GOVERNOR SPRING |

| 12/1. | [0] | 155407-1100 | SHIM D37&30.5T0.5 |

| 12/1. | [0] | 155407-1200 | SHIM D37&30.5T1.0 |

| 12/1. | [0] | 155407-1300 | SHIM D37&30.5T1.5 |

| 12/1. | [0] | 155407-1400 | SHIM D37&30.5T2.0 |

| 12/1. | [0] | 155407-1500 | SHIM D37&30.5T2.5 |

| 12/1. | [0] | 155407-1600 | SHIM D37&30.5T3.0 |

| 12/1. | [0] | 155407-1700 | SHIM D37&30.5T0.2 |

| 12/1. | [0] | 155407-1800 | SHIM D37&30.5T0.3 |

| 13. | [1] | 155240-0500 | COVER |

| 14. | [1] | 155019-0220 | FILLER PIECE |

| 15. | [4] | 020105-1640 | BLEEDER SCREW M5P0.8L16 |

| 15. | [4] | 020105-1640 | BLEEDER SCREW M5P0.8L16 |

| 18. | [1] | 155241-2220 | HEADLESS SCREW |

| 21. | [1] | 155245-0100 | HEXAGON NUT |

| 23. | [1] | 029142-0010 | CAPSULE |

| 26. | [1] | 029721-2050 | JOINT CONNECTION |

| 27. | [1] | 029721-2040 | JOINT CONNECTION |

| 31. | [1] | 155414-5500 | CONTROL LEVER |

| 40. | [1] | 155404-3700 | CAP |

| 50. | [1] | 014110-8440 | LOCKING WASHER |

| 51. | [1] | 013020-8040 | UNION NUT M8P1.25H7 |

| 100. | [1] | 029621-7010 | PACKING RING |

| 140. | [1] | 154390-0000 | GASKET |

Include in #1:

101433-9390

as GOVERNOR

Cross reference number

Zexel num

Bosch num

Firm num

Name

105520-3150

19200L2000 NISSAN

PNEUMATIC GOVERNOR

K 14JQ PNEUMATIC GOVERNOR GOV PG GOV

K 14JQ PNEUMATIC GOVERNOR GOV PG GOV

105520-3150

19200L2000 NISSAN-DIESEL

PNEUMATIC GOVERNOR

K 14JQ PNEUMATIC GOVERNOR GOV PG GOV

K 14JQ PNEUMATIC GOVERNOR GOV PG GOV

Information:

Removal of idler gearCamshaft End Play

Measure the camshaft end play, and, if the limit value is exceeded, replace the thrust plate.

Measurement of camshaft end playReversal of Crankcase

Gently lay the crankcase on its side, then turn the crankcase upside down.

Resting the crankcase with the oil pan on the bottom can cause the oil pan to crack.

Reversal of crankcaseRemoval of Oil Pan And Oil Pan Gasket

(1) Unscrew the oil pan mounting bolts, and detach the oil pan.(2) Remove the oil pan gasket.

Removal of oil pan and oil gasketRemoval of Oil Pump

Unscrew the oil pump set bolt, and pull out the oil pump.

Removal of oil pumpRemoval of Camshaft

Removal of camshaft(1) Position the camshaft gear so that the two lightening holes are on the top and bottom, then remove the thrust plate mounting bolts using the socket.(2) Pull out the camshaft from the crankcase.

Be careful not to damage the cams and bearing sections on the camshaft.

Removal of Front Plate

Removal of front plateUnscrew the front plate mounting bolts, and dismount the front plate (together with the injection pump) from the crankcase.Pistons, Connecting Rods, Crankshaft and Crankcase

When replacing the crankcase, remove all accessories (relief valve and others) carefully from the crankcase, and reinstall them on a new crankcase.Laying Crankcase on Its Side

Gently lay the crankcase on its side.

Laying crankcase on its sideMeasurement of Connecting Rod End Play

(1) Measure the clearance between the big-end of each connecting rod and the crankshaft (end play) with feeler gages. (2) If the measured clearance exceeds the limit value, replace the connecting rod.

Measurement of connecting rod End PlayRemoval of Connecting Rod Caps

(1) On each connecting rod and cap, put a mark indicating its cylinder No.(2) Remove the connecting rod caps.(3) For each removed connecting rod bearing (lower half), indicate the piston No. from which it was removed and the upper/lower identification. Be careful not to damage the bearings. Arrange the removed bearings in such a way that they can be reinstalled in their original positions during reassembly.

Removal of connecting rod capPreparation For Removal of Pistons

If carbon deposits are present at the upper sections of the cylinders, remove the carbon deposits with sandpaper and a cloth to facilitate piston removal.

Preparation for removal of pistonRemoval of Pistons

(1) Turn the crankshaft to bring the piston to be removed to the top dead center.(2) Using the wooden handle of a hammer, push the connecting rod on the cap contacting surface to remove the piston and connecting rod assembly from the top side of the cylinder.

Removal of pistonRemoval of Piston Ring

Using the piston ring pliers, remove the piston rings

Removal of piston ringRemoval of Piston Pins

Removal of piston pin(1) Using the snap ring pliers, remove the snap rings.(2) Pull out the piston pin, and separate the piston from the connecting rod.(3) If the piston pin cannot be remove easily, heat the piston with a piston heater or in hot water.Reversal of Crankcase

Gently stand the crankcase so that the oil pan mounting side faces up.

Reversal of crankcaseMeasurement of Crankshaft End Play

(1) With a dial gage positioned