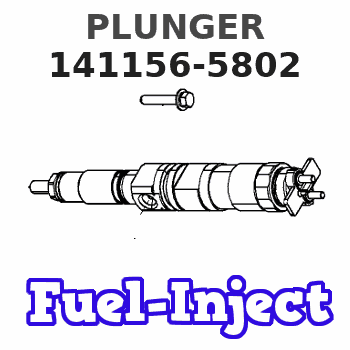

Information plunger

BOSCH

9 413 613 043

9413613043

ZEXEL

141156-5802

1411565802

ISHIKAWAJIMA-H

121015

121015

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$79.29

11 Feb 2019

Millennium: Millennium-Filters

Quincy 121015

Guaranteed to be Compatible with OEM product || Made in USA || Volume discounts available. Please contact customer service for quote. Shipping costs may vary up or down depending on geographic location and method of delivery. Customer will always receive lowest actual rate. || Photo images may be general representations of products and are updated periodically. || All products are guaranteed to be free from manufacturing defects and meet or exceed factory specifications in terms of fit, form and functionality.

Guaranteed to be Compatible with OEM product || Made in USA || Volume discounts available. Please contact customer service for quote. Shipping costs may vary up or down depending on geographic location and method of delivery. Customer will always receive lowest actual rate. || Photo images may be general representations of products and are updated periodically. || All products are guaranteed to be free from manufacturing defects and meet or exceed factory specifications in terms of fit, form and functionality.

$32.50

11 Feb 2019

Brady Worl: Brady Worldwide

121015 - Label Bmp21 Durable Pp 0.5X21 Ft RL2000 - Label BMP21 Durable PP 0.5X21 FT RL1 - Roll of 1

Description : LABEL BMP21 DURABLE PP 0.5X21 FT RL1 || Supplier No : 121015 || Unit : Roll of 1

Description : LABEL BMP21 DURABLE PP 0.5X21 FT RL1 || Supplier No : 121015 || Unit : Roll of 1

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

3406B and 3406C Non-Peec Engines

Steps 4 through 7 do not apply to PEEC engines.

Illustration 16. Install Lever Assembly

(1) 6N-3646 Lever. (2) 5P-0537 Washer. (3) 6V-8918 Bolt. (4) 9M-3858 Rack Preload Spring. (5) 1B-7182 Bolt.4. Install lever (1) with washer (2) and bolt (3).5. Install bolt (5) into hole as shown.6. Hook spring (4) between bolt (5) and lever (1).

Illustration 17. Install Rack Positioning Assembly

(1) 9U-5296 Rack Assembly. (2) Original cover mounting bolts or 4F-7957 Bolt.7. Install rack positioning assembly (1) with bolts (2). Use rack positioning assembly (1) as a "fuel ON" and "fuel OFF" control. Position the assembly to the full "fuel ON" position for all tests. Use the positioning assembly for rack adjustment.3406 Peec Engines

Steps 8 and 9 do not apply to Non-PEEC engines.

Illustration 18. Installing testing hardware for 3406 PEEC Engines

(1) 9U-5292 Rack Preload Assembly. (2) 9U-5120 Spanner Wrench. (3) 9U-5295 Positioning Assembly.8. Remove the BTM from the injection pump and install the 9U-5292 Rack Preload Assembly (1). Make sure the pin is properly located in the slot of the servo shaft. After installing the rack preload assembly, finger tighten the bolts.9. Remove the shut-off solenoid with a 9U-5120 Spanner Wrench (2) and install 9U-5295 Positioning Assembly (3). Use rack preload assembly (1) as a "fuel ON" and "fuel OFF" control. Position the assembly to the full "fuel ON" position for all tests. Use the positioning assembly for rack adjustment.Connect Hoses and Lines

Illustration 19. Connect Lube Oil Supply and Drain Hose

(1) 7G-7105 Hose. (2) 5P-6661 Fitting. (3) 9U-7709 Oil Drain Tube and two 5D-1026 Hose Clamps.

Illustration 20. Connect Fuel Supply and Return Lines

(4) 030-7947 Fitting, 3J-1907 O-ring Seal, and 7G-7105 Hose. (5) 8T-2160 Orifice Fitting, 3J-1907 O-ring Seal, and 7G-7105 Hose. (6) 9U-5298 Fuel Injection Line Tube Assembly (verify fuel line part number in TMI).1. Attach one end of hose (1) to the Lube Oil Supply fitting on the test stand. Attach the other end to the 5P-6661 Fitting on the rear support.2. Connect the oil drain tube (2) to the rear support and the test stand's stand-pipe with two hose clamps. On the AVM20-12C, the drain hose can be routed to the lube oil drain pan.3. Install fitting, O-ring, and hose (4) onto the fuel injection pump. Connect the other end of the hose to the "Test Oil Supply" connection on the test stand.4. Install fitting, O-ring, and hose (5) onto the fuel injection pump. Connect the other end of the hose to the "Test Oil Return" connection on the test stand.

Hold nut on 9U-6705 Master Nozzle when tightening fuel injection line tube assemblies (6). If the nut is not held in place during tightening, the master nozzle can be damaged.

5. Install six fuel injection line tube assemblies (6).Pre-Test Checks

1. Remove the lock-out on the electrical box, if installed.2. Release the Emergency Stop button.3. Start the bench and visually check for oil leaks from covers, hoses, etc.4. Check for oil flow through the drain tube. Also, check for oil flowing out of the oil

Steps 4 through 7 do not apply to PEEC engines.

Illustration 16. Install Lever Assembly

(1) 6N-3646 Lever. (2) 5P-0537 Washer. (3) 6V-8918 Bolt. (4) 9M-3858 Rack Preload Spring. (5) 1B-7182 Bolt.4. Install lever (1) with washer (2) and bolt (3).5. Install bolt (5) into hole as shown.6. Hook spring (4) between bolt (5) and lever (1).

Illustration 17. Install Rack Positioning Assembly

(1) 9U-5296 Rack Assembly. (2) Original cover mounting bolts or 4F-7957 Bolt.7. Install rack positioning assembly (1) with bolts (2). Use rack positioning assembly (1) as a "fuel ON" and "fuel OFF" control. Position the assembly to the full "fuel ON" position for all tests. Use the positioning assembly for rack adjustment.3406 Peec Engines

Steps 8 and 9 do not apply to Non-PEEC engines.

Illustration 18. Installing testing hardware for 3406 PEEC Engines

(1) 9U-5292 Rack Preload Assembly. (2) 9U-5120 Spanner Wrench. (3) 9U-5295 Positioning Assembly.8. Remove the BTM from the injection pump and install the 9U-5292 Rack Preload Assembly (1). Make sure the pin is properly located in the slot of the servo shaft. After installing the rack preload assembly, finger tighten the bolts.9. Remove the shut-off solenoid with a 9U-5120 Spanner Wrench (2) and install 9U-5295 Positioning Assembly (3). Use rack preload assembly (1) as a "fuel ON" and "fuel OFF" control. Position the assembly to the full "fuel ON" position for all tests. Use the positioning assembly for rack adjustment.Connect Hoses and Lines

Illustration 19. Connect Lube Oil Supply and Drain Hose

(1) 7G-7105 Hose. (2) 5P-6661 Fitting. (3) 9U-7709 Oil Drain Tube and two 5D-1026 Hose Clamps.

Illustration 20. Connect Fuel Supply and Return Lines

(4) 030-7947 Fitting, 3J-1907 O-ring Seal, and 7G-7105 Hose. (5) 8T-2160 Orifice Fitting, 3J-1907 O-ring Seal, and 7G-7105 Hose. (6) 9U-5298 Fuel Injection Line Tube Assembly (verify fuel line part number in TMI).1. Attach one end of hose (1) to the Lube Oil Supply fitting on the test stand. Attach the other end to the 5P-6661 Fitting on the rear support.2. Connect the oil drain tube (2) to the rear support and the test stand's stand-pipe with two hose clamps. On the AVM20-12C, the drain hose can be routed to the lube oil drain pan.3. Install fitting, O-ring, and hose (4) onto the fuel injection pump. Connect the other end of the hose to the "Test Oil Supply" connection on the test stand.4. Install fitting, O-ring, and hose (5) onto the fuel injection pump. Connect the other end of the hose to the "Test Oil Return" connection on the test stand.

Hold nut on 9U-6705 Master Nozzle when tightening fuel injection line tube assemblies (6). If the nut is not held in place during tightening, the master nozzle can be damaged.

5. Install six fuel injection line tube assemblies (6).Pre-Test Checks

1. Remove the lock-out on the electrical box, if installed.2. Release the Emergency Stop button.3. Start the bench and visually check for oil leaks from covers, hoses, etc.4. Check for oil flow through the drain tube. Also, check for oil flowing out of the oil