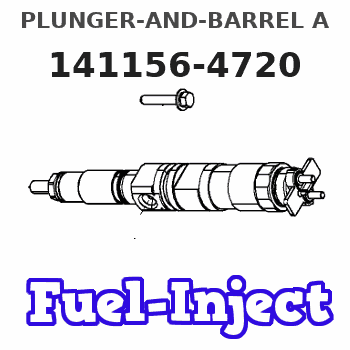

Information plunger-and-barrel a

BOSCH

9 443 610 363

9443610363

ZEXEL

141156-4720

1411564720

Rating:

Include in ###:

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

AIR COMPRESSOR: The air compressor which supplies pressure air is a two cylinder unit and is gear driven. The moving parts are lubricated from the diesel engine crankcase lubricating oil system. The compressor is liquid cooled and is connected through lines to the diesel engine cooling system.Every 10,000 miles inspect air compressor air cleaner. The time to replace the air compressor air cleaner is determined by inspection. Install a new element if plugged or oil soaked. Replace element every 20,000 miles regardless of condition.

AIR COMPRESSOR AIR CLEANEREvery 100,000 miles rebuild or install a rebuilt or new air compressor. This component should be checked and rebuilt in a well equipped shop with proper tools and personnel familiar with disassembly and assembly procedures. Thoroughly inspect all connections for tightness before placing vehicle in use.DRAIN AIR TANKS: Drain moisture from the air storage tanks at the end of each days run. Open the drain cocks at the bottom of the tank. Some air systems have automatic moisture ejector valves which can also be operated manually. Refer to the truck manufacturer's manual for maintenance procedures.TIGHTEN ENGINE MOUNTING BOLTS: When giving the engine a seasonal check, tighten all mounting bolts and nuts. Replace damaged, broken or lost bolts. See BOLT, NUT AND TAPERLOCK STUD SPECIFICATIONS.Major Inspection Maintenance

These items are of major checks which require partial disassembly and should be performed by experienced personnel. If it is determined that parts are worn beyond limits, remove the engine and completely rebuild.Oil consumption, combustion gas blow by, loss of power, and other signs of wear should be taken into consideration and analyzed to determine if the engine can be operated for another service interval.CRANKSHAFT END CLEARANCE: When engine is being rebuilt or at the 200,000 mile interval, check the crankshaft end clearance. The check can be made by attaching a dial indicator against the crankshaft pulley or vibration damper while prying against the vibration damper and pulley hub. End clearance should not exceed .035 inches (0,89 mm). Do not pry against outer diameter of vibration damper.CRANKSHAFT SEALS: When engine is being rebuilt or at the 300,000 mile interval or if oil leakage is occuring, replace seals.REBUILD CYLINDER HEAD: Irregular engine operation and excessive white or blue smoke can be caused by leaky valves and/or worn valve guides. The cylinder head must be removed for further inspection and reconditioning. Your authorized dealer is equipped to analyze the problem and recondition the cylinder head and valve components.

AIR COMPRESSOR AIR CLEANEREvery 100,000 miles rebuild or install a rebuilt or new air compressor. This component should be checked and rebuilt in a well equipped shop with proper tools and personnel familiar with disassembly and assembly procedures. Thoroughly inspect all connections for tightness before placing vehicle in use.DRAIN AIR TANKS: Drain moisture from the air storage tanks at the end of each days run. Open the drain cocks at the bottom of the tank. Some air systems have automatic moisture ejector valves which can also be operated manually. Refer to the truck manufacturer's manual for maintenance procedures.TIGHTEN ENGINE MOUNTING BOLTS: When giving the engine a seasonal check, tighten all mounting bolts and nuts. Replace damaged, broken or lost bolts. See BOLT, NUT AND TAPERLOCK STUD SPECIFICATIONS.Major Inspection Maintenance

These items are of major checks which require partial disassembly and should be performed by experienced personnel. If it is determined that parts are worn beyond limits, remove the engine and completely rebuild.Oil consumption, combustion gas blow by, loss of power, and other signs of wear should be taken into consideration and analyzed to determine if the engine can be operated for another service interval.CRANKSHAFT END CLEARANCE: When engine is being rebuilt or at the 200,000 mile interval, check the crankshaft end clearance. The check can be made by attaching a dial indicator against the crankshaft pulley or vibration damper while prying against the vibration damper and pulley hub. End clearance should not exceed .035 inches (0,89 mm). Do not pry against outer diameter of vibration damper.CRANKSHAFT SEALS: When engine is being rebuilt or at the 300,000 mile interval or if oil leakage is occuring, replace seals.REBUILD CYLINDER HEAD: Irregular engine operation and excessive white or blue smoke can be caused by leaky valves and/or worn valve guides. The cylinder head must be removed for further inspection and reconditioning. Your authorized dealer is equipped to analyze the problem and recondition the cylinder head and valve components.