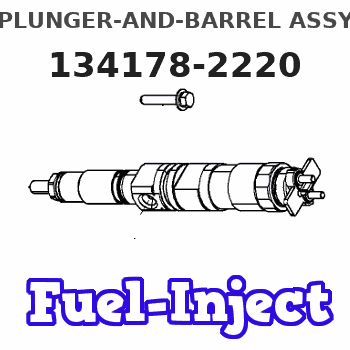

Information plunger-and-barrel assy

BOSCH

9 443 610 598

9443610598

ZEXEL

134178-2220

1341782220

HINO

221043560A

221043560a

Rating:

Include in ###:

Number on scheme 7/1

1080623210

as PLUNGER-AND-BARREL ASSY

1080623213

as PLUNGER-AND-BARREL ASSY

PT48

1080623570

as PLUNGER-AND-BARREL ASSY

1080823561

as PLUNGER-AND-BARREL ASSY

PT48

1080823570

as PLUNGER-AND-BARREL ASSY

Cross reference number

Zexel num

Bosch num

Firm num

Name

134178-2220

9 443 610 598

221043560A HINO

PLUNGER-AND-BARREL ASSY

C 14ED PLUNGER ASSY PL(HD-TICS) PL

C 14ED PLUNGER ASSY PL(HD-TICS) PL

Information:

Typical 12 Volt Starting Circuit

(1) Test point. (2) Test point. (3) Test Point. (4) Test Point. (5) Test Point. (X) Hold-in coil. (W) Pull-in coil.General Information

All starting systems are made up of four elements. They are the ignition switch, start relay, the starting motor solenoid and starting motor. The only exception to this is that on some small engines the start relay may not be required. In this case, the start switch powers the starting motor solenoid directly.Start switches are relatively low current devices. They are rated to switch approximately 5 to 20 amps. Because the coil of a start relay [between test point (1) and (2)] draws about 1 amp, the start switch can easily turn on the start relay and have long life.The switch contacts of a typical start relay are rated to switch between 100 and 300 amps. Because the solenoid requires 5 to 50 amps, the start relay can easily switch this load.The starting motor solenoid has two functions: 1) it engages the pinion with the flywheel, and 2) it is a high current switch rated about 1000 amps that actually turns on the starting motor.The starting motor solenoid has two coils. Pull-in coil (W) draws about 40 amps and hold-in coil (X) requires about 5 amps. The instant the start relay closes, both coils (W) and (X) receive power. Battery voltage is applied to the high end of both coils, at test point (3) which is the start (S) terminal. The low end of hold-in coil (X) is permanently grounded to the ground post or motor housing of the starting motor. Grounding for the low end, test point (4), of pull-in coil (W) is momentary, and takes place through the DC resistance of the starting motor. As soon as magnetic force builds in both coils, the pinion moves toward the flywheel ring gear. The pinion will stop short of engagement of the flywheel ring gear. Only then will the solenoid contacts close to power the starting motor. This temporarily removes the ground from pull-in coil (W), and puts battery voltage on both ends of it while the starting motor cranks. During this period, the pull-in coil is out of the circuit. Cranking continues until power to the solenoid is broken by releasing the ignition switch.The result of these switches and relays is to permit a 5 amp dash-mounted switch to turn on a 500 to 1000 amp motor used to crank an engine.Battery voltage (power) available during cranking varies according to the temperature of the batteries. The following chart is a guide as to what to expect from a normal system. The next chart shows maximum acceptable voltage loss in the high current battery circuit feeding the starting motor. These values are maximums for machines of approximately 2000 SMH and up. Newer machines would be less than those shown. Voltages greater than those shown are most often caused by loose and/or corroded connections or defective switch contacts.Diagnosis Procedure

Do not operate the starting motor

Have questions with 134178-2220?

Group cross 134178-2220 ZEXEL

Hino

134178-2220

9 443 610 598

221043560A

PLUNGER-AND-BARREL ASSY