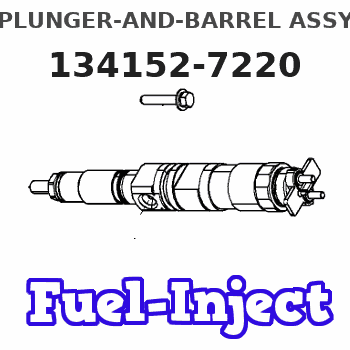

Information plunger-and-barrel assy

BOSCH

9 413 610 292

9413610292

ZEXEL

134152-7220

1341527220

ISUZU

1156320060

1156320060

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$61.03

02 May 2024

CN: Diesel Injection Par

Cabezales 6Pcs Fuel Injection Plunger Barrel Assembly 134152-7220 P252 9413610292 Engine Pump Element Fits for ISUZU Forward 6SD1 6SD1T

Cabezales Manufacturer MFR Number:134152-7220,9 413 610 292 ,9413610292,1341527220 ,1156320060 Stamping No.: P252. || Package: 6 pieces of plunger and barrel.Neutral packing. || Application:Fits for ISUZU Forward 6SD1 6SD1T . || Premium Quality:Our plungers and barrels made of premium strength metal and composite plastic.we have a good air and fuel mixing ability and excellent ability of fuel pump systems,and plunger assembly be inspected reliability and durability in the factory. || Notice:Please you carefully check your vehicle plunger barrel and make sure that the number must be completely the same as our description fitment,if you have any problem,please you contact us by email,we will have professional customer service within 24 hours.

Cabezales Manufacturer MFR Number:134152-7220,9 413 610 292 ,9413610292,1341527220 ,1156320060 Stamping No.: P252. || Package: 6 pieces of plunger and barrel.Neutral packing. || Application:Fits for ISUZU Forward 6SD1 6SD1T . || Premium Quality:Our plungers and barrels made of premium strength metal and composite plastic.we have a good air and fuel mixing ability and excellent ability of fuel pump systems,and plunger assembly be inspected reliability and durability in the factory. || Notice:Please you carefully check your vehicle plunger barrel and make sure that the number must be completely the same as our description fitment,if you have any problem,please you contact us by email,we will have professional customer service within 24 hours.

Include in ###:

Number on scheme 7/2

1060617360

as PLUNGER-AND-BARREL ASSY

1060617910

as PLUNGER-AND-BARREL ASSY

P252

1060617911

as PLUNGER-AND-BARREL ASSY

Cross reference number

Zexel num

Bosch num

Firm num

Name

134152-7220

9 413 610 292

1156320060 ISUZU

PLUNGER-AND-BARREL ASSY

C 14EU PLUNGER ASSY PL(P) PL

C 14EU PLUNGER ASSY PL(P) PL

Information:

Cat does not warrant the quality or performance of non-Cat fluids.

Do NOT mix brands or types of SCA. Do NOT mix SCAs and extenders.Failure to follow the recommendations can result in shortened cooling system component life.

Use Only Approved SCAs. Conventional coolants require the maintenance addition of SCA throughout their expected life. Do NOT use an SCA with a coolant unless specifically approved by the coolant supplier for use with their coolant. It is the responsibility of the coolant manufacturer to ensure compatibility and acceptable performance.Failure to follow the recommendations can result in shortened cooling system component life.

Follow the maintenance information provided in the “Coolant and General Maintenance Recommendations” section in this Special Publication.Select a commercial diesel engine antifreeze coolant that meets all the requirements given in Table 1. The table contains the requirements for coolant to meet the published service intervals.The provided requirements are applicable to finished coolants and not for the concentrates. When concentrated coolant/antifreeze is mixed, Cat recommends mixing the concentrate with distilled water or with deionized water. If distilled water or deionized water is not available, water which has the required properties may be used. For the water properties, refer to this Special Publication, "General Coolant Information" article.Coolant/antifreezes for heavy-duty applications that meet "ASTM D6210" do not require treatment with SCA at the initial fill. Use the recommended 1:1 or higher concentration with recommended water. Treatment with SCA is required on a maintenance basis.The SCA manufacturer is responsible for ensuring the SCA is compatible with water meeting the “Caterpillar Minimum Acceptable Water Quality Requirements” as found in this Special Publication, and "ASTM D6210-08, Table X1.1". The coolant manufacturer and the SCA manufacturer are responsible to ensure that the products will not cause cooling system harm.Do not mix brands or types of coolants with different brands or types of SCA or extender.If using non Cat coolants, refer to the coolant manufacturer for information on a compatible SCA.Treat the compatible commercial coolant with 3 to 6 percent Cat SCA by volume. Maintain a 3 to 6 percent concentration level of SCA in the cooling system. For more information, refer to this Special Publication, "Conventional Coolant/Antifreeze Cooling System Maintenance" article.

Table 1

Technical Requirements for Commercial Diesel Engine Antifreeze Coolants

Specifications ASTM D6210-08

Additional Requirements Silicon: 100 ppm minimum to 275 ppm maximum

Nitrites: maintained at 1200ppm (70 grains/US gal) minimum to 2400 ppm (140 grains/US gal) maximum

Cat SCA at 3 to 6 percent (if Cat SCA is added)

Maintenance ASTM D6210-08 Add compatible SCA at maintenance intervals

Clean and flush the cooling system at drain intervals

Have questions with 134152-7220?

Group cross 134152-7220 ZEXEL

Isuzu

134152-7220

9 413 610 292

1156320060

PLUNGER-AND-BARREL ASSY