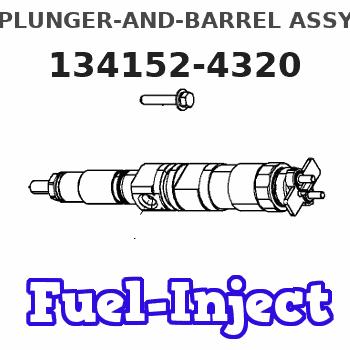

Information plunger-and-barrel assy

BOSCH

9 443 610 589

9443610589

ZEXEL

134152-4320

1341524320

HINO

221281110A

221281110a

Rating:

Include in ###:

Number on scheme 7/2

1060615801

as PLUNGER-AND-BARREL ASSY

1060617441

as PLUNGER-AND-BARREL ASSY

P223

1060670520

as PLUNGER-AND-BARREL ASSY

1060670830

as PLUNGER-AND-BARREL ASSY

P223

Cross reference number

Zexel num

Bosch num

Firm num

Name

134152-4320

9 443 610 589

221281110A HINO

PLUNGER-AND-BARREL ASSY

C 14EU PLUNGER ASSY PL(P) PL

C 14EU PLUNGER ASSY PL(P) PL

134152-4320

9 443 610 589

S221281110 HINO

PLUNGER-AND-BARREL ASSY

A C 14EU PLUNGER ASSY PL(P) PL

A C 14EU PLUNGER ASSY PL(P) PL

Information:

Personal injury can result from being struck by parts propelled by a released spring force.Make sure to wear all necessary protective equipment.Follow the recommended procedure and use all recommended tooling to release the spring force.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Dispose of all fluids according to local regulations and mandates.

If possible, take the fuel injection pump to a clean work area.

Clean the outside surfaces of the fuel injection pump.

Illustration 1 g03117860

Typical example

Place a suitable container under the fuel injection pump to collect any fuel from the fuel injection pump. Use a suitable tool to loosen the drain plug (1). If necessary, retain the fuel collected for analysis if required.

Illustration 2 g03117878

Typical example

Use a suitable pair of pliers to remove the throttle return spring (2).Note: Care should be taken when the spring is removed.

Illustration 3 g03117896

Typical example

Loosen self-locking nut (3). Do not remove the nut.

Illustration 4 g03117916

Typical example

Use a suitable pair of pliers to lift and disconnect throttle spring (4). Remove self-locking nut (3), washer, upper retainer, spring, lower retainer, spacer, lever, and dust cap.Note: Care should be taken when the spring is removed.

Illustration 5 g03117938

Typical example

Remove four screws (6) in the governor cover (7). Gently push the throttle shaft (5) down into the cover (7).

Illustration 6 g03117956

Typical example

To inspect the internal components of the fuel injection pump, gently lift and rotate the cover (7).Note: The cover is still connected internally, if resistance is felt, lower the cover and move the cover backwards. Attempt to lift the cover again.

Inspect the internal components of the fuel injection pump. Refer to steps 9a and 9b.

Illustration 7 g03117961

Typical example

If good quality fuel is being used, the components will be clean. Refer to illustration 7. Take photographs of the identification plate of the fuel injection pump and any evidence found. Attach the photographs to support the claim story.

Illustration 8 g03118119

Typical example

Illustration 9 g03118121

Typical example

If the injection pump has been run with excessive water in the fuel, there will be signs of rust and oxidization of the steel components. Refer to illustration 8. Fuel with dirt ingress will show a build-up of dirt on the components. Refer to illustration 9.Note: Issues with the fuel injection pump that are due to dirt and water void Caterpillar warranty. Advise the customer on the correct fuel, maintenance, and fuel storage procedures. Refer to the relevant Operation and Maintenance Manual for more information.If the fuel injection pump shows signs that contaminated fuel is the root cause of the problem, the evidence can be shown to the customer immediately.After the fuel injection pump has been inspected, the fuel injection pump must not be used in service.Rebuild the fuel injection pump. Refer to steps 1 to 6

Lower the cover (7) back into position. Ensure the throttle shaft (5), has been returned to the original position.

Install the four screws (6) to the cover (7). Tighten the

Have questions with 134152-4320?

Group cross 134152-4320 ZEXEL

Hino

134152-4320

9 443 610 589

221281110A

PLUNGER-AND-BARREL ASSY

134152-4320

9 443 610 589

S221281110

PLUNGER-AND-BARREL ASSY