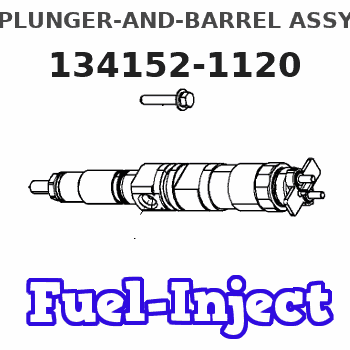

Information plunger-and-barrel assy

BOSCH

9 443 610 682

9443610682

ZEXEL

134152-1120

1341521120

ISUZU

1156320030

1156320030

Rating:

Include in ###:

Number on scheme 7/2

1060607980

as PLUNGER-AND-BARREL ASSY

P191

1060670680

as PLUNGER-AND-BARREL ASSY

1060671020

as PLUNGER-AND-BARREL ASSY

P191

Cross reference number

Zexel num

Bosch num

Firm num

Name

134152-1120

9 443 610 682

1156320030 ISUZU

PLUNGER-AND-BARREL ASSY

C 14EU PLUNGER ASSY PL(P) PL

C 14EU PLUNGER ASSY PL(P) PL

134152-1120

9 443 610 682

ME741405 MITSUBISHI

PLUNGER-AND-BARREL ASSY

C 14EU PLUNGER ASSY PL(P) PL

C 14EU PLUNGER ASSY PL(P) PL

Information:

Illustration 1 g00563639

Schematic of the RTD module

Illustration 2 g00563641

Schematic of the RTD

Illustration 3 g00562911

Schematic of the RTDFunctional Test

Check the electrical connectors and check the wiring.

Bodily contact with electrical potential can cause bodily injury or death.To avoid the possibility of injury or death, ensure that the main power supply has been disconnected before performing any maintenance or removing any modules.

Disconnect the power supply.

Check the electrical connectors and check the wiring for damage or bad connections.

Verify that all modules are properly seated.

Verify the status of the LED on the SLC 5/04.The results of the preceding procedure are in the following list:

All of the components are fully installed. All of the components are free of corrosion. All of the components are free of damage. All of the modules are properly seated. Proceed to 2.

The components are not fully installed. The components are not free of corrosion. The components are damaged. All of the modules are not properly seated. Repair the component. Verify that the repair resolves the problem. STOP.

Check the RTD.

Bodily contact with electrical potential can cause bodily injury or death.To avoid the possibility of injury or death, ensure that the main power supply has been disconnected before performing any maintenance or removing any modules.

Disconnect the RTD from the wiring harness. This is done by removing the RTD connector head.

Measure the resistance on the sensor. Measure the resistance between the following terminals: Terminal 1 and Terminal 2.

Use table 1 in order to determine if the RTD is functioning normally.

Table 1

RTD

Temperature and Resistance

Temperature Ohms Difference per °C

0 °C (32 °F) 100.00 0.39

10 °C (50.0 °F) 103.90 0.39

20 °C (68 °F) 107.79 0.39

30 °C (86 °F) 111.67 0.39

40 °C (104 °F) 115.54 0.39

50 °C (122 °F) 119.40 0.39

60 °C (140 °F) 123.24 0.38

70 °C (158 °F) 127.07 0.38

80 °C (176 °F) 130.89 0.38

90 °C (194 °F) 134.70 0.38

100 °C (212 °F) 138.50 0.38

110 °C (230 °F) 142.29 0.38

120 °C (248 °F) 146.06 0.38

130 °C (266 °F) 149.82 0.37

140 °C (284 °F) 153.58 0.37

150 °C (302 °F) 157.31 0.37 The results of the preceding procedure are in the following list:

The resistance is correct. The RTD is functioning normally. Proceed to 3.

The resistance is not correct. The RTD is not functioning normally. Replace the RTD. Stop.

Measure the resistance of the interconnect wiring harness.

Connect the RTD to the wiring harness. This is done by connecting the RTD connector head.

Locate the RTD terminal and locate the sense terminal. The terminals are located in the MECP. The RTD terminal is terminal 2 and the sense terminal is terminal 3.Reference: Schematic, RENR2458, "3600 Diesel Marine Monitoring System Electrical System".

Measure the resistance on the

Have questions with 134152-1120?

Group cross 134152-1120 ZEXEL

Isuzu

134152-1120

9 443 610 682

1156320030

PLUNGER-AND-BARREL ASSY

Mitsubishi

134152-1120

9 443 610 682

ME741405

PLUNGER-AND-BARREL ASSY