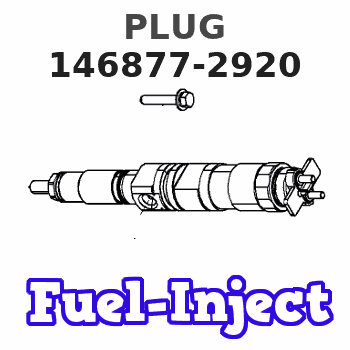

Information plug

BOSCH

9 461 615 603

9461615603

ZEXEL

146877-2920

1468772920

ISUZU

8971443780

8971443780

Rating:

Include in ###:

Number on scheme 117/1

1047414940

as PLUG

1047417400

as PLUG

L=7.1

1047417420

as PLUG

1047417430

as PLUG

L=7.1

1047417440

as PLUG

1047417490

as PLUG

L=7.1

1047427044

as PLUG

1047427113

as PLUG

L=7.1

1047427270

as PLUG

1047427272

as PLUG

L=7.1

1047427310

as PLUG

1047427381

as PLUG

L=7.1

1047427390

as PLUG

1047427450

as PLUG

L=7.1

1047427451

as PLUG

1047427460

as PLUG

L=7.1

1047427461

as PLUG

Cross reference number

Zexel num

Bosch num

Firm num

Name

146877-2920

9 461 615 603

8971443780 ISUZU

PLUG

C 11FV CLOSING PLUG parts(VE) Others

C 11FV CLOSING PLUG parts(VE) Others

Information:

2. Loosen the fuel injection line nut at the fuel pump, one at a time, with the engine running. Use a cloth or similar material to prevent fuel from spraying on hot exhaust component. Be sure to tighten each fuel line nut after the test, before the next fuel line nut is loosened. 3. When a cylinder is found where the loosened fuel line nut does not make a difference in engine performance or smoking, have that cylinder injection nozzle tested. Purge the fuel lines of air. 4. Check for any fuel leaks. Stop the engine by following the procedure in the Engine Stopping topic in this manual and correct any fuel leaks that may occur. To Remove and Install Injection Nozzles

Special tooling is required. Refer to the Service Manual for your engine to remove and install injection nozzles or contact your Caterpillar dealer for assistance.Starting Motor and Alternator

Inspect for Proper Operation

Electric Starting Motor

AlternatorFor good life of the air starting motor, the air supply should be free of dirt and water. A lubricator should be used with the starting system. Use 10 weight non-detergent engine oil above 0°C (32°F) or diesel fuel at temperatures below 0°C (32°F). See the Lubricant Specifications for the proper oil to use.One unscheduled failure caused by any of these components will cost more in downtime than maintaining them before failure. The cost incurred to maintain these components before failure as recommended could be significantly less than if the component fails. By maintaining these components before failure, unscheduled downtime and potential damage to other engine parts are reduced. The prevention of unscheduled downtime saves money and lowers operating costs.Caterpillar recommends that the most cost effective method of operation and maintenance for these components is to inspect the unit before it fails and make the decision to rebuild or exchange the components.Before deciding which repair method is best, make sure all of the options and costs associated with repair have been considered. Some considerations are:* The costs associated with using separate parts from inventory versus the cost of a repair kit.* Downtime costs while the product is being rebuilt or repaired.* Total parts and labor costs for repairs versus the actual Remanufactured cost.* Remanufactured components from Caterpillar (if available) are covered by a standard, factory warranty.Caterpillar Recommendation

To minimize downtime, Caterpillar recommends that the use of Remanufactured components (subject to availability) is the most cost effective option.Removal and Installation

Refer to the established procedure in the Service Manual for this engine to Remove and Install these components or contact your Caterpillar dealer for assistance.Turbochargers

Rebuild or Exchange

The cost incurred to maintain your turbochargers before failure as recommended could be significantly less than if you wait until your turbocharger fails. By maintaining your turbochargers before failure, you will minimize unscheduled downtime and reduce the chances for potential damage to other engine parts. If you choose to operate your engine until the turbochargers fail, your repair costs could be as much as twenty-five times or more compared

Special tooling is required. Refer to the Service Manual for your engine to remove and install injection nozzles or contact your Caterpillar dealer for assistance.Starting Motor and Alternator

Inspect for Proper Operation

Electric Starting Motor

AlternatorFor good life of the air starting motor, the air supply should be free of dirt and water. A lubricator should be used with the starting system. Use 10 weight non-detergent engine oil above 0°C (32°F) or diesel fuel at temperatures below 0°C (32°F). See the Lubricant Specifications for the proper oil to use.One unscheduled failure caused by any of these components will cost more in downtime than maintaining them before failure. The cost incurred to maintain these components before failure as recommended could be significantly less than if the component fails. By maintaining these components before failure, unscheduled downtime and potential damage to other engine parts are reduced. The prevention of unscheduled downtime saves money and lowers operating costs.Caterpillar recommends that the most cost effective method of operation and maintenance for these components is to inspect the unit before it fails and make the decision to rebuild or exchange the components.Before deciding which repair method is best, make sure all of the options and costs associated with repair have been considered. Some considerations are:* The costs associated with using separate parts from inventory versus the cost of a repair kit.* Downtime costs while the product is being rebuilt or repaired.* Total parts and labor costs for repairs versus the actual Remanufactured cost.* Remanufactured components from Caterpillar (if available) are covered by a standard, factory warranty.Caterpillar Recommendation

To minimize downtime, Caterpillar recommends that the use of Remanufactured components (subject to availability) is the most cost effective option.Removal and Installation

Refer to the established procedure in the Service Manual for this engine to Remove and Install these components or contact your Caterpillar dealer for assistance.Turbochargers

Rebuild or Exchange

The cost incurred to maintain your turbochargers before failure as recommended could be significantly less than if you wait until your turbocharger fails. By maintaining your turbochargers before failure, you will minimize unscheduled downtime and reduce the chances for potential damage to other engine parts. If you choose to operate your engine until the turbochargers fail, your repair costs could be as much as twenty-five times or more compared