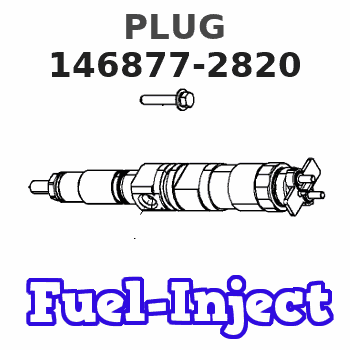

Information plug

BOSCH

9 461 615 602

9461615602

ZEXEL

146877-2820

1468772820

ISUZU

8971443770

8971443770

Rating:

Include in ###:

Number on scheme 117/1

1047414940

as PLUG

1047417400

as PLUG

L=7.0

1047417420

as PLUG

1047417430

as PLUG

L=7.0

1047417440

as PLUG

1047417490

as PLUG

L=7.0

1047427044

as PLUG

1047427113

as PLUG

L=7.0

1047427270

as PLUG

1047427272

as PLUG

L=7.0

1047427310

as PLUG

1047427381

as PLUG

L=7.0

1047427390

as PLUG

1047427450

as PLUG

L=7.0

1047427451

as PLUG

1047427460

as PLUG

L=7.0

1047427461

as PLUG

Cross reference number

Zexel num

Bosch num

Firm num

Name

146877-2820

9 461 615 602

8971443770 ISUZU

PLUG

C 11FV CLOSING PLUG parts(VE) Others

C 11FV CLOSING PLUG parts(VE) Others

Information:

You must read and understand the warnings and instructions contained in the Safety section of this manual before performing any operation or maintenance procedures.Before proceeding with this maintenance interval, perform previous maintenance interval requirements. Perform the maintenance at the interval listed in the Maintenance Schedule for your engine.Engine Protection Controls

Inspect For Proper Operation

The engine protective alarm and shutoff controls must be tested, inspected and checked by an authorized Caterpillar dealer at least every year or 1000 hours for proper operation. The manual shutoff functions should be tested to ensure proper operation and protection to the engine. Refer to Engine Control, Monitoring and Protection in the Operation Section in this Manual. Have the checks made by a qualified mechanic. Consult your authorized Caterpillar engine dealer, or refer to the Service Manual for your engine. Check Alarm and Shutdown Settings

Check for loose, broken, or damaged wiring or components. Check the condition of all sensors and wiring. Repair or replace any broken or malfunctioning sensors before they become a problem. The inspection only takes a few minutes and could avert a potential problem that could cause your engine to fail. Check GSC Display Window Readings

Refer to the operating parameters in the Engine Control, Monitoring and Protection topic.While operating, observe all GSC display window readings hourly, especially the engine oil pressure, fuel pressure and coolant temperature.Operational Checks

Start the engine. Use the starting procedure found in the Engine Starting topic in this publication.The operational checks are intended to check the engine starting and stopping, lubrication and fuel systems as well as overall operation. The checks should take no longer than five minutes to complete. Longer periods of operation are not required. A more thorough Performance Analysis should be performed with the engine operating under load.Automatic Switches

Check that all switches are in proper position for automatic start. The shutoff controls must be checked so that they function properly when they are required. To prevent damage to the engine while performing the test, only authorized personnel or your Caterpillar dealer should perform the checks.SR4 Generator

Make sure residual voltage in the rotor, stator and the generator is discharged.If this generator is to be connected to a utility electrical distribution system, it must be isolated from the distribution system by means of:a. Opening the main switch in the case of the generator temporarily connected to the system or,b. A double throw (transfer) switch in the case of a permanent connection to the system.Failure to do so could result in personal injury or death due to electrical shock. This warning does not apply when a generator and utility distribution system are designed and approved by the utility to run in parallel.

Before working inside the generator, make sure that the starting motor can not be activated by any automatic or manual signal.Electronic components in the regulator can be damaged during generator operation if contact is made between the part and ground.

Check Winding Insulation Resistance

When the engine-generator is operating, voltages up to 600V are present in these areas near

Inspect For Proper Operation

The engine protective alarm and shutoff controls must be tested, inspected and checked by an authorized Caterpillar dealer at least every year or 1000 hours for proper operation. The manual shutoff functions should be tested to ensure proper operation and protection to the engine. Refer to Engine Control, Monitoring and Protection in the Operation Section in this Manual. Have the checks made by a qualified mechanic. Consult your authorized Caterpillar engine dealer, or refer to the Service Manual for your engine. Check Alarm and Shutdown Settings

Check for loose, broken, or damaged wiring or components. Check the condition of all sensors and wiring. Repair or replace any broken or malfunctioning sensors before they become a problem. The inspection only takes a few minutes and could avert a potential problem that could cause your engine to fail. Check GSC Display Window Readings

Refer to the operating parameters in the Engine Control, Monitoring and Protection topic.While operating, observe all GSC display window readings hourly, especially the engine oil pressure, fuel pressure and coolant temperature.Operational Checks

Start the engine. Use the starting procedure found in the Engine Starting topic in this publication.The operational checks are intended to check the engine starting and stopping, lubrication and fuel systems as well as overall operation. The checks should take no longer than five minutes to complete. Longer periods of operation are not required. A more thorough Performance Analysis should be performed with the engine operating under load.Automatic Switches

Check that all switches are in proper position for automatic start. The shutoff controls must be checked so that they function properly when they are required. To prevent damage to the engine while performing the test, only authorized personnel or your Caterpillar dealer should perform the checks.SR4 Generator

Make sure residual voltage in the rotor, stator and the generator is discharged.If this generator is to be connected to a utility electrical distribution system, it must be isolated from the distribution system by means of:a. Opening the main switch in the case of the generator temporarily connected to the system or,b. A double throw (transfer) switch in the case of a permanent connection to the system.Failure to do so could result in personal injury or death due to electrical shock. This warning does not apply when a generator and utility distribution system are designed and approved by the utility to run in parallel.

Before working inside the generator, make sure that the starting motor can not be activated by any automatic or manual signal.Electronic components in the regulator can be damaged during generator operation if contact is made between the part and ground.

Check Winding Insulation Resistance

When the engine-generator is operating, voltages up to 600V are present in these areas near