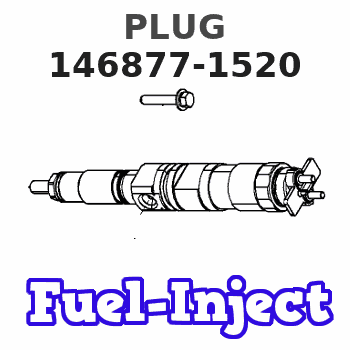

Information plug

BOSCH

9 461 615 589

9461615589

ZEXEL

146877-1520

1468771520

ISUZU

8971443640

8971443640

Rating:

Include in ###:

Number on scheme 117/1

1047414930

as PLUG

L=5.7

1047414940

as PLUG

1047414941

as PLUG

L=5.7

1047414950

as PLUG

1047414952

as PLUG

L=5.7

1047414960

as PLUG

1047414961

as PLUG

L=5.7

1047417050

as PLUG

1047417400

as PLUG

L=5.7

1047417420

as PLUG

1047417430

as PLUG

L=5.7

1047417440

as PLUG

1047417490

as PLUG

L=5.7

1047427044

as PLUG

1047427113

as PLUG

L=5.7

1047427270

as PLUG

1047427272

as PLUG

L=5.7

1047427310

as PLUG

1047427381

as PLUG

L=5.7

1047427390

as PLUG

Cross reference number

Zexel num

Bosch num

Firm num

Name

146877-1520

9 461 615 589

8971443640 ISUZU

PLUG

C 11FV CLOSING PLUG parts(VE) Others

C 11FV CLOSING PLUG parts(VE) Others

Information:

Priming the Fuel System

Fuel leaked or spilled on to hot surfaces or electrical components can cause a fire. Clean up fuel spills immediately.

Prime the fuel system to fill dry fuel filters and purge trapped air. The fuel system requires priming after:* being run dry* storage* fuel filter cleaning/replacement If the engine does not have a fuel priming pump, go to step 4.1. Unlock and operate the priming pump until a resistance is felt. A considerable number of pump strokes may be required.2. Push in and hand-tighten the plunger.3. Crank the engine. If the engine starts, but runs rough, continue running the engine at low idle until the engine runs smoothly.

Do not crank the engine for more than 30 seconds. If the engine does not start, allow the starter motor to cool for two minutes before cranking again.

If the engine will not start, or once started, continues to misfire or smoke, further priming is necessary. Repeat steps 1 through 3. If operating problems persist after repeating steps 1 through 3, further priming is necessary.4. Open the vent valve (if equipped) on the fuel injection pump housing.

DO NOT remove the plug in the fuel filter base (for the fuel pressure sending unit [if equipped]) to purge air from the fuel system. Periodic removal of the plug will result in increased wear of the threads in the fuel filter base and lead to fuel leakage.

5. Operate the priming pump until the flow of fuel from the vent valve is continuous and free of air bubbles. If the engine does not have a fuel priming pump, crank the engine until the fuel flows free of air bubbles. Do not crank the engine for more than 30 seconds. Allow the starter to cool for two minutes before cranking again.6. Close the vent valve. Push in and hand-tighten the plunger.7. Crank the engine. If the engine starts, but runs rough, continue running the engine at low idle until the engine runs smoothly. If the engine will not start, or once started, continues to misfire or smoke, further priming is necessary.8. Loosen the fuel line nuts, one at a time, at the valve cover base.

A fuel injection nozzle will be damaged if the top of the nozzle turns in the body. The engine will be damaged if a defective fuel injection nozzle is used because the fuel spray pattern that comes out of the nozzle will be incorrect. Fuel injection nozzles can be permanently damaged by twisting if only one wrench is used to loosen or tighten the fuel line nuts. Do NOT let the tops of the fuel nozzles turn when the fuel lines are loosened. Use one wrench to hold the nozzle and another to loosen the fuel line nut.

Operate the priming pump plunger until the flow of fuel from the fuel line is continuous and free of air bubbles. Push the plunger in and tighten by hand. If the engine does not have a fuel priming pump, crank the engine.Tighten each fuel

Fuel leaked or spilled on to hot surfaces or electrical components can cause a fire. Clean up fuel spills immediately.

Prime the fuel system to fill dry fuel filters and purge trapped air. The fuel system requires priming after:* being run dry* storage* fuel filter cleaning/replacement If the engine does not have a fuel priming pump, go to step 4.1. Unlock and operate the priming pump until a resistance is felt. A considerable number of pump strokes may be required.2. Push in and hand-tighten the plunger.3. Crank the engine. If the engine starts, but runs rough, continue running the engine at low idle until the engine runs smoothly.

Do not crank the engine for more than 30 seconds. If the engine does not start, allow the starter motor to cool for two minutes before cranking again.

If the engine will not start, or once started, continues to misfire or smoke, further priming is necessary. Repeat steps 1 through 3. If operating problems persist after repeating steps 1 through 3, further priming is necessary.4. Open the vent valve (if equipped) on the fuel injection pump housing.

DO NOT remove the plug in the fuel filter base (for the fuel pressure sending unit [if equipped]) to purge air from the fuel system. Periodic removal of the plug will result in increased wear of the threads in the fuel filter base and lead to fuel leakage.

5. Operate the priming pump until the flow of fuel from the vent valve is continuous and free of air bubbles. If the engine does not have a fuel priming pump, crank the engine until the fuel flows free of air bubbles. Do not crank the engine for more than 30 seconds. Allow the starter to cool for two minutes before cranking again.6. Close the vent valve. Push in and hand-tighten the plunger.7. Crank the engine. If the engine starts, but runs rough, continue running the engine at low idle until the engine runs smoothly. If the engine will not start, or once started, continues to misfire or smoke, further priming is necessary.8. Loosen the fuel line nuts, one at a time, at the valve cover base.

A fuel injection nozzle will be damaged if the top of the nozzle turns in the body. The engine will be damaged if a defective fuel injection nozzle is used because the fuel spray pattern that comes out of the nozzle will be incorrect. Fuel injection nozzles can be permanently damaged by twisting if only one wrench is used to loosen or tighten the fuel line nuts. Do NOT let the tops of the fuel nozzles turn when the fuel lines are loosened. Use one wrench to hold the nozzle and another to loosen the fuel line nut.

Operate the priming pump plunger until the flow of fuel from the fuel line is continuous and free of air bubbles. Push the plunger in and tighten by hand. If the engine does not have a fuel priming pump, crank the engine.Tighten each fuel