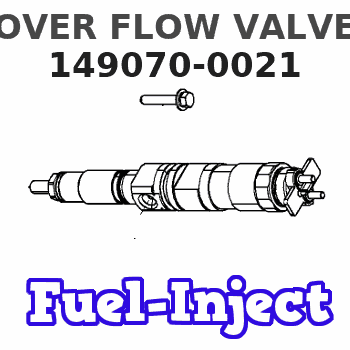

Information over flow valve

BOSCH

1 467 445 003

1467445003

ZEXEL

149070-0021

1490700021

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Generic Fuel Overflow Return Valve for Dodge Ram 2500 3500 P7100 Cummins 5.9L 1467445003 1417413047

Generic Stable characteristics,high reliability. || Easy installation. || No instruction included || The color is as the photoes show

Generic Stable characteristics,high reliability. || Easy installation. || No instruction included || The color is as the photoes show

IEQFUE 2PCS Pump Overflow Valve 1417413047 1467445003 3941156 P7100 Compatible with Dodge Cummins 5.9L 1998-2002

IEQFUE 【Part Name】Overflow Valve || 【Part Number】1417413047,1 417 413 047 ,4089577 ,3941156 ,1467445003, P7100 || 【Application Models For】Compatible with1998-2002 Dodge Cummins 5.9L

IEQFUE 【Part Name】Overflow Valve || 【Part Number】1417413047,1 417 413 047 ,4089577 ,3941156 ,1467445003, P7100 || 【Application Models For】Compatible with1998-2002 Dodge Cummins 5.9L

$20.99

10 Oct 2023

US: JEM&JULES

Overflow Valve for Dodge Ram 2500 3500 5.9L Diesel 1994-1998, Injection Pump Overflow Return Valve, 1417413047, 3941156 4089577 1467445003

Gxcdizx ➽【Fitment】Overflow return pressure regulator valve for 1994-1998.5 Dodge Ram 2500 5.9L, for 1994-1998 Dodge Ram 3500 5.9L || ➽【Replaces Part Number】3941156, 1467445003, 1417413047, 4089577 || ➽【Premium Quality】Overflow return pressure regulator valve made of high quality iron materials, which will built performance and prevent water and corrosion, this overflow valve is the new style with the ball type spring retainer, not the old double bolt head type. || ➽【Direct Fit】Direct replacement for a proper fit and easy installation, quality materials used, meets or exceeds OEM standards, 100% tested before shipping. || ➽【Best Service】Please contact us if you received the part damaged or if the part you ordered did not fix your problem.We would like to ensure 100% customer satisfaction for you.

Gxcdizx ➽【Fitment】Overflow return pressure regulator valve for 1994-1998.5 Dodge Ram 2500 5.9L, for 1994-1998 Dodge Ram 3500 5.9L || ➽【Replaces Part Number】3941156, 1467445003, 1417413047, 4089577 || ➽【Premium Quality】Overflow return pressure regulator valve made of high quality iron materials, which will built performance and prevent water and corrosion, this overflow valve is the new style with the ball type spring retainer, not the old double bolt head type. || ➽【Direct Fit】Direct replacement for a proper fit and easy installation, quality materials used, meets or exceeds OEM standards, 100% tested before shipping. || ➽【Best Service】Please contact us if you received the part damaged or if the part you ordered did not fix your problem.We would like to ensure 100% customer satisfaction for you.

Include in ###:

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Illustration 7 g06347860

Injector male spade terminals

There are two options to build injector adapter harness for C3.3.If available, use the injector connector removed from C3.3 harness. Cut both 100 mm wires from the connector and attach bullet terminals that fit in the injector adapter harness C3.8 terminal from injector test kit.If no harness is available, build a harness with the following. Two female spade terminals for injector male spade terminal, two 16 gauge 100 mm wires, and two bullet terminals for injector adapter harness C3.8 terminal.

Illustration 8 g06345429

Injector adapter harness C2.4

Illustration 9 g06346223

Injector adapter harness C3.8

Illustration 10 g06346237

Injector male spade terminals

There are two options to build injector adapter harness for C2.4.If available, use the injector connector removed from C2.4 harness. Cut both 100 mm wires from the connector and attach bullet terminals that fit in the injector adapter harness C3.8 terminal from injector test kit.If no harness is available, build a harness with the following. Two female spade terminals for injector male spade terminal, two 16 gauge 100 mm wires, and two bullet terminals for injector adapter harness C3.8 terminal.Injector Test Set-up

Illustration 11 g06346391

Mounted nozzle test group

Find a suitable stable and surface to either mount or place the nozzle test group. Fill fuel container with #1 diesel and install high-pressure hose assembly. Use adaptors, if needed, based on nozzle tester. Tighten the fuel line adapter to (25 ft lbs). Install the fuel line adapter and tighten to (25 ft lbs) to allow connection to the injector.

Illustration 12 g06346423

Injector holder assembly

Take the injector test kit and remove all parts to assemble, as shown above. Take the injector holder and the clear fuel shield with screws from the kit and remove the screws using a 3mm alan wrench. Assemble the parts so the clear fuel shield with screws is on the bottom. While, the mounted injector holder is on top with the screws removed from before.

Illustration 13 g06346719

Fuel collector and injector holder

Place injector holder onto a fuel collector or another container to capture the injection spray.

Illustration 14 g06346839

Injector setup and harness connection

Install the injector that is needing to be tested into the opening at the top of injector holder. Attach the return fuel drain hose and run the drain hose to another fuel collector. Make the harness connection using the correct adapter for the C2.4, C3.3, and C3.8 engines. Connect the injector pulse tool and the injector adapter harness to the injector.

Illustration 15 g06346868

Complete setup of nozzle tester and injector test kit

Once injector test kit and nozzle test group are set up, connect fuel line adaptor on the high-pressure hose assembly to the injector, leave connection loose. Actuate the lever on the nozzle test group until fuel drips from connection allowing air to purge from setup. Tighten fuel line adaptor at injector to (25 ft lbs).Injector Test Procedure

Illustration 16 g06346881

Mounted nozzle test group (close-up)

Inspect the injector for any leaks. Using the lever on the nozzle tester group, build injection fuel pressure to (5000 psi). Turn the locking valve to insure there is no leakage back through the tester.

Let the nozzle test