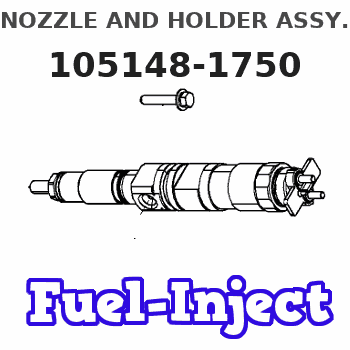

Information nozzle and holder assy.

BOSCH

9 430 613 930

9430613930

ZEXEL

105148-1750

1051481750

YANMAR

12993153000

12993153000

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

3PCS Fuel Injector 119717-53000 11971753000 119717-53001 129931-53000 Compatible for Yanmar 3TNV76 4TNE92 Engine

ZFBBM High precision: able to control the time, pressure, and quantity of fuel injection with extremely high precision, ensuring the accuracy and consistency of fuel injection. || Adjustability: the fuel injector can adjust the flow rate and injection angle of liquid materials as needed to achieve the best effect. || Excellent: Our tools are made of excellent steel with high hardness, high stability and high strength, exceeding OEM standards and helping you save money in the long run. || Fuel-Efficient Injector: High efficient fuel sprays and High Impedance Coil enable fast start up in the cold environments, low fuel consumption, and better performance. || Commodity confidence: Each product has been professionally inspected and professionally packaged to ensure the integrity of the product.

ZFBBM High precision: able to control the time, pressure, and quantity of fuel injection with extremely high precision, ensuring the accuracy and consistency of fuel injection. || Adjustability: the fuel injector can adjust the flow rate and injection angle of liquid materials as needed to achieve the best effect. || Excellent: Our tools are made of excellent steel with high hardness, high stability and high strength, exceeding OEM standards and helping you save money in the long run. || Fuel-Efficient Injector: High efficient fuel sprays and High Impedance Coil enable fast start up in the cold environments, low fuel consumption, and better performance. || Commodity confidence: Each product has been professionally inspected and professionally packaged to ensure the integrity of the product.

Jeimgrso 4pcs Fuel injector 129931-53000 12993153000 for Yanmar 4TNE92 Engine

Jeimgrso Item Name: Fuel injector || Part Number: 129931-53000 12993153000 || Compatible with Yanmar 4TNE92 Engine || Note: To ensure you order the correct part, please check if the number of your previous part is exactly the same as the number(s) stated in the listing. || Note: Due to differences between different displays, the picture may not reflect the actual color of the item. We guarantee that the style is the same as shown in the picture.

Jeimgrso Item Name: Fuel injector || Part Number: 129931-53000 12993153000 || Compatible with Yanmar 4TNE92 Engine || Note: To ensure you order the correct part, please check if the number of your previous part is exactly the same as the number(s) stated in the listing. || Note: Due to differences between different displays, the picture may not reflect the actual color of the item. We guarantee that the style is the same as shown in the picture.

DoraKvi 3-Pieces 129931-53000 12993153000 Fuel Injector Compatible with Yanmar 3TNV76 4TNE92 Engine for Kubota 3D76E-6 Engine

DoraKvi 🌟 Part Name :Fuel Injector || 🌟 Part Number : 129931-53000 12993153000 || 🌟 Application : Compatible with Yanmar 3TNV76 4TNE92 Engine for Kubota 3D76E-6 Engine || ✅ Accurate ✅- In Order To Avoid Unnecessary Return. Please follow the old part number and machine model to find the right product, if you are not sure, please contact us, we are more than happy to provide services. || 💠 Reliable performance 💠-DoraKvi- our products have been carefully designed and tested, with high reliability and stability, can maintain good working condition for a long time.

DoraKvi 🌟 Part Name :Fuel Injector || 🌟 Part Number : 129931-53000 12993153000 || 🌟 Application : Compatible with Yanmar 3TNV76 4TNE92 Engine for Kubota 3D76E-6 Engine || ✅ Accurate ✅- In Order To Avoid Unnecessary Return. Please follow the old part number and machine model to find the right product, if you are not sure, please contact us, we are more than happy to provide services. || 💠 Reliable performance 💠-DoraKvi- our products have been carefully designed and tested, with high reliability and stability, can maintain good working condition for a long time.

You can express buy:

USD 65

29-06-2025

29-06-2025

3Pc Fuel Injector 119717-53000 11971753000 119717-53001 129931-53000 For Yanmar 3TNV76 4TNE92 Engine

USD 40.33

14-06-2025

14-06-2025

XCWoOshop 3Pc Fuel Injector 119717-53000 11971753000 119717-53001 129931-53000 For Yanmar 3TNV76 4TNE92 Engine

Images:

USD 196

[19-May-2025]

USD 26.54

[19-May-2025]

USD 115

[19-May-2025]

USD 115.99

[13-May-2025]

Include in #2:

104742-7390

as NOZZLE AND HOLDER ASSY

Cross reference number

Zexel num

Bosch num

Firm num

Name

105148-1750

12993153000 YANMAR

NOZZLE AND HOLDER ASSY.

4TNE94L K 53KJ NOZZLE & HOLDER ASSY N&NH KCA-P N&NH

4TNE94L K 53KJ NOZZLE & HOLDER ASSY N&NH KCA-P N&NH

Information:

The 169-3374 Injector Sleeve Removal Group is used to remove the brass injector sleeves on 3176 and 3176B Engines, only. This tool group is used with the 9U-6860 Sleeve Replacement Group . The tool group eliminates the tapping and threading operation of the current 9U-6860 Sleeve Replacement Group . The benefits of this method of sleeve removal are easier sleeve removal and little debris that could enter the engine. This tool group uses a crimping die and captured stud similar to the current 3100 Sleeve Removal Tool. This tool group can be used with the cylinder head either on or off the engine.Additional Contact Information

For additional product support questions concerning this tool, contact the Dealer Service Tools Hotline at:USA: 1-800-542-8665, Option 1International: 1-309-578-7372Injector Sleeve Removal

Remove the rocker arms from the cylinder being repaired.

Remove the injector.

Illustration 4 g02888499

Put Sleeve Stud (3) into Injector Sleeve

Drop 142-8280 Sleeve Stud (3) into the injector sleeve and ensure that stud is resting at the bottom of the injector sleeve. The flat disc part of the sleeve stud should be below the top edge of the brass sleeve.

Illustration 5 g02888500

Insert Crimping Swage (9) Into Bore And Over Sleeve Stud (3)

Apply a light coating of grease to the inside cutting edge of crimping swage (9) and insert into the injector bore. Make sure that the tool is resting on the top edge of the brass sleeve by turning or "wiggling" slightly. It is possible for the tool to rest on the casting ledge (indicated by the arrow) in the cylinder head. The threads of sleeve stud (3) should go into the center hole of crimping swage (9), as shown in Figure 5.

Illustration 6 g02888508

Drive Crimping Swage (9) Down Into Injector Sleeve

Using a large hammer, strike the top of crimping swage (9) firmly and squarely. Drive down into the injector bore until the bottom slot is level with the top deck of the cylinder head, as shown in Figure 6.

Illustration 7 g02888509

Remove Driving Swage (9) With Crows Foot Pry Bar (12)

Remove the crimping swage from the injector bore. If the tool is stuck in the bore, use a crows foot pry bar (12) in the slot to work out the tool. Many times there will be a small amount of brass caught between crimping swage (9) and the injector bore causing the tool to stick. When the tool is removed, the top of the brass sleeve should be rolled over, trapping sleeve stud (3) inside the injector sleeve.Note: The sharp edge of crimping swage (9) must remain sharp and free of nicks or damage. This tool may be resharpened only on the inside cutting edge. Any sharpening procedure that reduces the OD of the cutting edge will result in poor tool performance and tool sticking.

Illustration 8 g02888517

Insert Sleeve Jaw (4)

Insert 151-4833 Sleeve Jaw (4) into the injector bore. The sharp edge of the sleeve jaw is designed to lock the rolled-over brass material between the sleeve stud and the sleeve jaw. The sleeve stud is then prevented from

For additional product support questions concerning this tool, contact the Dealer Service Tools Hotline at:USA: 1-800-542-8665, Option 1International: 1-309-578-7372Injector Sleeve Removal

Remove the rocker arms from the cylinder being repaired.

Remove the injector.

Illustration 4 g02888499

Put Sleeve Stud (3) into Injector Sleeve

Drop 142-8280 Sleeve Stud (3) into the injector sleeve and ensure that stud is resting at the bottom of the injector sleeve. The flat disc part of the sleeve stud should be below the top edge of the brass sleeve.

Illustration 5 g02888500

Insert Crimping Swage (9) Into Bore And Over Sleeve Stud (3)

Apply a light coating of grease to the inside cutting edge of crimping swage (9) and insert into the injector bore. Make sure that the tool is resting on the top edge of the brass sleeve by turning or "wiggling" slightly. It is possible for the tool to rest on the casting ledge (indicated by the arrow) in the cylinder head. The threads of sleeve stud (3) should go into the center hole of crimping swage (9), as shown in Figure 5.

Illustration 6 g02888508

Drive Crimping Swage (9) Down Into Injector Sleeve

Using a large hammer, strike the top of crimping swage (9) firmly and squarely. Drive down into the injector bore until the bottom slot is level with the top deck of the cylinder head, as shown in Figure 6.

Illustration 7 g02888509

Remove Driving Swage (9) With Crows Foot Pry Bar (12)

Remove the crimping swage from the injector bore. If the tool is stuck in the bore, use a crows foot pry bar (12) in the slot to work out the tool. Many times there will be a small amount of brass caught between crimping swage (9) and the injector bore causing the tool to stick. When the tool is removed, the top of the brass sleeve should be rolled over, trapping sleeve stud (3) inside the injector sleeve.Note: The sharp edge of crimping swage (9) must remain sharp and free of nicks or damage. This tool may be resharpened only on the inside cutting edge. Any sharpening procedure that reduces the OD of the cutting edge will result in poor tool performance and tool sticking.

Illustration 8 g02888517

Insert Sleeve Jaw (4)

Insert 151-4833 Sleeve Jaw (4) into the injector bore. The sharp edge of the sleeve jaw is designed to lock the rolled-over brass material between the sleeve stud and the sleeve jaw. The sleeve stud is then prevented from