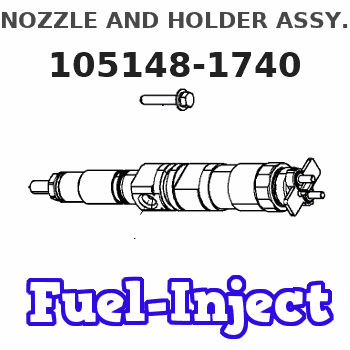

Information nozzle and holder assy.

BOSCH

9 430 613 924

9430613924

ZEXEL

105148-1740

1051481740

ISHIKAWAJIMA-S

131406500

131406500

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

JPCIFIRQ Injector, 131406500 Fuel Injector 1051481740 9430613924 Compatible for Perkins Engine 404C-22 403C-15

JPCIFIRQ Re-assembly with new high-quality components (seals, filters) || Promote the smooth operation of the engine and balance the fuel delivery, and reduce the overall fuel consumption and harmful emissions. || Made of high quality materials, corrosion-resistant, corrosion-resistant and durable. || Convenient installation, fast response, stable performance and close effect. || Smaller fuel atomized particles improve engine fuel economy.

JPCIFIRQ Re-assembly with new high-quality components (seals, filters) || Promote the smooth operation of the engine and balance the fuel delivery, and reduce the overall fuel consumption and harmful emissions. || Made of high quality materials, corrosion-resistant, corrosion-resistant and durable. || Convenient installation, fast response, stable performance and close effect. || Smaller fuel atomized particles improve engine fuel economy.

131406500 Fuel Injector 1051481740 9430613924 Compatible With Perkins Engine 404C-22 403C-15

YJEMORLIX 🚗 Optimize engine performance, stop vehicle vibration, accelerate more smoothly. || 🚗 Super atomizing effect, high injection pressure, better atomizing effect, more full combustion. || 🚗 Promote smooth engine operation and balanced fuel delivery, reduce the overall fuel consumption. || 🚗 Atomized fuel into the engine intake manifold or cylinder, improve reliability and durability. || 🚗 Please confirm whether the nozzle is the same as your model before purchase.

YJEMORLIX 🚗 Optimize engine performance, stop vehicle vibration, accelerate more smoothly. || 🚗 Super atomizing effect, high injection pressure, better atomizing effect, more full combustion. || 🚗 Promote smooth engine operation and balanced fuel delivery, reduce the overall fuel consumption. || 🚗 Atomized fuel into the engine intake manifold or cylinder, improve reliability and durability. || 🚗 Please confirm whether the nozzle is the same as your model before purchase.

You can express buy:

USD 23.75

19-05-2025

19-05-2025

131406500 105148-1740 1051481740 131406490 131406360 252-1446 replace for Perkins injector Carter 3014.3013C.C1.5.C2.2

Images:

USD 8.39

[14-Jun-2025]

USD 35.99

[14-Jun-2025]

USD 20

[17-May-2025]

USD 199.4

[14-Jun-2025]

Cross reference number

Zexel num

Bosch num

Firm num

Name

105148-1740

131406500 ISHIKAWAJIMA-S

NOZZLE AND HOLDER ASSY.

E672 K 53KJ NOZZLE & HOLDER ASSY N&NH KCA-P N&NH

E672 K 53KJ NOZZLE & HOLDER ASSY N&NH KCA-P N&NH

Information:

The troubleshooting chart provides a definite sequence to be followed for a logical procedure to determine the frequency and amplitude of vibration so that the source of the vibration can be located and corrected.1. The customer must be asked questions to determine whether his complaint is valid, or whether his diagnosis of the actual problem is correct.Some of the questions that must be asked are as follows:a. What components are vibrating?b. In what speed range does this vibration become excessive?c. Does clutch operation affect the vibration?d. What is the history of the problem?2. Run the engine through the idle speed range and note all vibrating components. Look for any loose or broken mounts, brackets, and fasteners. Repair and tighten any fixtures.3. Check idle speed range with clutch disengaged. If vibrations subside, there is a balance problem with the clutch disc. The clutch disc must be repaired or replaced.4. Further analysis requires the use of a vibration instrument. Any instrument which can accurately measure the displacement of the vibration (usually in mils-inch/1000) and the frequency (cycles per second) will be sufficient. A vibration instrument such as the IRD Mechanalysis Model 320 or an equivalent instrument can be used to analyze vibration.5. Measure vibration of cab components which have the objectionable vibration.Run engine slowly through the speed range and measure vibration with the instrument filter OUT. When peak amplitudes are found, run the engine at the speeds they occur and with the instrument filter IN, find the frequency of the vibration.If the frequency of vibration is 1/2 times of engine rpm (1/2 order), the vibration is caused by a cylinder misfiring. This must be corrected before further vibration analysis is made.If the frequency of vibration is 3 times engine rpm, no corrective action can be taken on the engine because this is the firing frequency of the 3306 engine. The problem is in the cab or chassis resonance.If frequency is some order other than 1/2 or 3rd, then further measurements must be made on the engine.6. Measurements taken on the engine must be made perpendicular to the crankshaft at the front and, rear of the engine in vertical and horizontal directions.7. Record all vibrations over 4.0 mils and the engine rpm at which it occurs (100 rpm intervals are sufficient) with instrument filter OUT. Note any sudden increase and decrease in amplitudes. These occur in resonant speed ranges.If no amplitudes exceed 4.0 mils, the engine is within Caterpillar Specifications.If amplitudes exceed 4.0 mils, the vibrations must be measured with the instrument filter IN to obtain the frequency of the vibrations.8. Run the engine at high idle. With the instrument filter IN, check the frequency range and record any amplitudes over 4.0 mils and the corresponding frequency. Analysis of vibrations for the possible causes is done by identifying the frequency of the vibration and where on the engine it is the greatest magnitude. Make reference to Special Instruction, Troubleshooting Engine Vibration In Vehicular Equipment, SEHS7914 for additional information for troubleshooting vibration complaints.