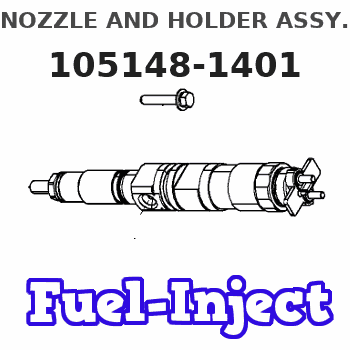

Information nozzle and holder assy.

BOSCH

9 430 610 435

9430610435

ZEXEL

105148-1401

1051481401

MITSUBISHI

ME201844

me201844

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

fuel injector 4PCS Diesel Fuel Injectors Nozzles 8 Ring Replace Kit Compatible For Mitsubishi Delica Spacegear Pajero 4M40 4M40T 2.8L ME201844 9430610435

XEUOOHFX Fast start-up and smooth acceleration, full power, high reliability || High-quality materials, long life, reasonable and safe in production structure, easy to install in original data, comfortable driving without abnormal noise || Improve fuel efficiency, good atomization effect and more sufficient combustion, more accurate fuel injection, and achieve energy-saving and fuel-saving effects || Make emissions meet the standards, burn the residual oil to dry, and reduce black smoke emissions more reasonable, and optimize engine performance for a long time || 4PCS Diesel Fuel Injectors Nozzles 8 Ring Replace Kit Compatible For Mitsubishi Delica Spacegear Pajero 4M40 4M40T 2.8L ME201844 9430610435

XEUOOHFX Fast start-up and smooth acceleration, full power, high reliability || High-quality materials, long life, reasonable and safe in production structure, easy to install in original data, comfortable driving without abnormal noise || Improve fuel efficiency, good atomization effect and more sufficient combustion, more accurate fuel injection, and achieve energy-saving and fuel-saving effects || Make emissions meet the standards, burn the residual oil to dry, and reduce black smoke emissions more reasonable, and optimize engine performance for a long time || 4PCS Diesel Fuel Injectors Nozzles 8 Ring Replace Kit Compatible For Mitsubishi Delica Spacegear Pajero 4M40 4M40T 2.8L ME201844 9430610435

HAOSHUN 2 PCS Fuel Injector ME201844 for Mitsubishi Delica Spacegear Pajero 4M40 4M40T 2.8L

HAOSHUN Part Name:Fuel Injector || Part Number:ME201844 || APPlication: Compatible with Mitsubishi Delica Spacegear Pajero 4M40 4M40T 2.8L || 1.We Only Ship To Confirmed Order Addresses. Your Order Address Must Match Your Shipping Address. || 2.in Order To Avoid Unnecessary Return,please Check The Product Picture And Part Number Carefully To Make Sure It Is The Product You Want

HAOSHUN Part Name:Fuel Injector || Part Number:ME201844 || APPlication: Compatible with Mitsubishi Delica Spacegear Pajero 4M40 4M40T 2.8L || 1.We Only Ship To Confirmed Order Addresses. Your Order Address Must Match Your Shipping Address. || 2.in Order To Avoid Unnecessary Return,please Check The Product Picture And Part Number Carefully To Make Sure It Is The Product You Want

Diesel Fuel Injector Nozzle, ME201844, 9430610435, Compatible With Mitsubishi, Delica Spacegear Pajero 4M40 4M40T 2.8L

Tgmplhfv Improve fuel efficiency || Precision engineering diesel injector nozzles || Optimal fuel atomization and engine performance || The durability of high-quality structures under extreme conditions || The simple installation process is designed to seamlessly blend with your vehicle's fuel

Tgmplhfv Improve fuel efficiency || Precision engineering diesel injector nozzles || Optimal fuel atomization and engine performance || The durability of high-quality structures under extreme conditions || The simple installation process is designed to seamlessly blend with your vehicle's fuel

You can express buy:

USD 93.33

29-06-2025

29-06-2025

4pcs Diesel Fuel Injectors Nozzles 8 Ring Replace Kit For Mitsubishi Delica Spacegear Pajero 4M40 4M40T 2.8L ME201844 9430610435

Images:

USD 68.18

[24-Jun-2025]

USD 64.86

[14-Jun-2025]

USD 39.51

[14-Jun-2025]

Include in #2:

104701-3000

as NOZZLE AND HOLDER ASSY

Cross reference number

Zexel num

Bosch num

Firm num

Name

105148-1401

ME201844 MITSUBISHI

NOZZLE AND HOLDER ASSY.

4M40T1 K 53KJ NOZZLE & HOLDER ASSY N&NH KCA-P N&NH

4M40T1 K 53KJ NOZZLE & HOLDER ASSY N&NH KCA-P N&NH

Information:

Start By:a. remove cylinder head assemblyb. remove front housing groupc. remove flywheel housingd. remove crankshaft rear seal assemblye. remove piston and connecting rod assemblies 1. Remove bolts (1). Remove main bearing caps (2). Remove thrust bearings (3) from the center main. Main bearing caps are identified by numbers one through seven. Unmarked caps should be marked by stamping the appropriate number toward the right side on the bottom prior to the removal. 2. Install a suitable size bolt in each end of the crankshaft as shown. Fasten two lifting straps (4) to the bolts in the crankshaft and to a hoist as shown. Carefully, remove the crankshaft. The appropriate weight of the crankshaft is 129 kg (285 lb).3. Remove the upper portions of the main bearings. The following steps are for the installation of the crankshaft.

Be sure the main bearing tabs engage with the grooves in the block and cap.

4. Position the upper portion of the main bearings in the cylinder block. Lower the main bearing portion in caps (2). Be sure everything is clean and only the bearing face is lubricated with clean engine oil.5. Fasten a hoist to the crankshaft, and position it in the cylinder block. 6. Install thrust bearings (3).7. Install main bearing caps (2) with the part numbers toward the right hand side of the cylinder block. Take care to ensure the caps are numbered one through seven from the front of the engine. Put clean engine oil or molylube on the bolt threads and the washer face; then install bolts (1). Tighten the bolts on the side where the main bearing tabs are located to a torque of 95 5 N m (70 4 lb ft). Tighten the bolts on the opposite side to a torque of 95 5 N m (70 4 lb ft).8. Put a mark on each bolt head and the bearing caps. Turn the bolts that are opposite the main bearing tabs an additional 90° 5° turn. Then turn the bolts on the side where the main bearing tabs are located an additional 90° 5° turn.

Typical Example9. Use tooling (A) to measure crankshaft end play. The crankshaft end play must be 0.10 to 0.50 mm (.004 to .020 in).End By:a. install piston and connecting rod assembliesb. install crankshaft rear seal assemblyc. install flywheel housingd. install front housing groupe. install cylinder head assembly

Be sure the main bearing tabs engage with the grooves in the block and cap.

4. Position the upper portion of the main bearings in the cylinder block. Lower the main bearing portion in caps (2). Be sure everything is clean and only the bearing face is lubricated with clean engine oil.5. Fasten a hoist to the crankshaft, and position it in the cylinder block. 6. Install thrust bearings (3).7. Install main bearing caps (2) with the part numbers toward the right hand side of the cylinder block. Take care to ensure the caps are numbered one through seven from the front of the engine. Put clean engine oil or molylube on the bolt threads and the washer face; then install bolts (1). Tighten the bolts on the side where the main bearing tabs are located to a torque of 95 5 N m (70 4 lb ft). Tighten the bolts on the opposite side to a torque of 95 5 N m (70 4 lb ft).8. Put a mark on each bolt head and the bearing caps. Turn the bolts that are opposite the main bearing tabs an additional 90° 5° turn. Then turn the bolts on the side where the main bearing tabs are located an additional 90° 5° turn.

Typical Example9. Use tooling (A) to measure crankshaft end play. The crankshaft end play must be 0.10 to 0.50 mm (.004 to .020 in).End By:a. install piston and connecting rod assembliesb. install crankshaft rear seal assemblyc. install flywheel housingd. install front housing groupe. install cylinder head assembly