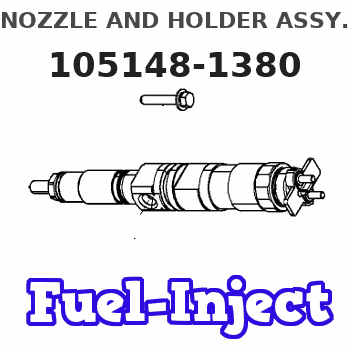

Information nozzle and holder assy.

BOSCH

9 430 610 431

9430610431

ZEXEL

105148-1380

1051481380

ISUZU

8971160990

8971160990

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Heavy Equipment Parts & Accessories – Durable High-Performance Replacement Parts Fuel Injector 105148-1551 105148-1380 105148-1110 105148-1280 for Zexel Model-Z59-FX1870

Generic ✔ Premium Quality & Durability – Manufactured with high-grade materials to ensure long-lasting performance in demanding industrial and construction environments. || ✔ Wide Compatibility – Designed to fit various heavy equipment brands and models, including excavators, loaders, bulldozers, and more for seamless installation. || ✔ Enhanced Performance & Efficiency – Engineered to withstand extreme conditions, reducing downtime and increasing the lifespan of your machinery. || ✔ Easy Installation & Maintenance – Precise fitment and hassle-free setup make replacements quick and efficient, saving time and labor costs. || ✔ Reliable Supplier – Sourced from trusted manufacturers with strict quality control standards, ensuring timely superior product reliability.

Generic ✔ Premium Quality & Durability – Manufactured with high-grade materials to ensure long-lasting performance in demanding industrial and construction environments. || ✔ Wide Compatibility – Designed to fit various heavy equipment brands and models, including excavators, loaders, bulldozers, and more for seamless installation. || ✔ Enhanced Performance & Efficiency – Engineered to withstand extreme conditions, reducing downtime and increasing the lifespan of your machinery. || ✔ Easy Installation & Maintenance – Precise fitment and hassle-free setup make replacements quick and efficient, saving time and labor costs. || ✔ Reliable Supplier – Sourced from trusted manufacturers with strict quality control standards, ensuring timely superior product reliability.

Heavy Equipment Parts & Accessories – Durable High-Performance Replacement Parts 3X Fuel Injector 8971160990 33800-42500 1051481551 for Hyundai Isuzu Model-Z59-FX3645

Generic ✔ Premium Quality & Durability – Manufactured with high-grade materials to ensure long-lasting performance in demanding industrial and construction environments. || ✔ Wide Compatibility – Designed to fit various heavy equipment brands and models, including excavators, loaders, bulldozers, and more for seamless installation. || ✔ Enhanced Performance & Efficiency – Engineered to withstand extreme conditions, reducing downtime and increasing the lifespan of your machinery. || ✔ Easy Installation & Maintenance – Precise fitment and hassle-free setup make replacements quick and efficient, saving time and labor costs. || ✔ Reliable Supplier – Sourced from trusted manufacturers with strict quality control standards, ensuring timely superior product reliability.

Generic ✔ Premium Quality & Durability – Manufactured with high-grade materials to ensure long-lasting performance in demanding industrial and construction environments. || ✔ Wide Compatibility – Designed to fit various heavy equipment brands and models, including excavators, loaders, bulldozers, and more for seamless installation. || ✔ Enhanced Performance & Efficiency – Engineered to withstand extreme conditions, reducing downtime and increasing the lifespan of your machinery. || ✔ Easy Installation & Maintenance – Precise fitment and hassle-free setup make replacements quick and efficient, saving time and labor costs. || ✔ Reliable Supplier – Sourced from trusted manufacturers with strict quality control standards, ensuring timely superior product reliability.

$215.33

14 Nov 2024

CN: David-Store

3PCS Fuel Injector 8971160990 1051481380 Fits for Isuzu 3LA1 3LB1 Engine

CNCJNXW ★Part Name★:3PCS Fuel Injector || ★Part Number★:8971160990 1051481380 || ★Application★:Fits for Isuzu 3LA1 3LB1 Engine || NOTE Please check the part number before purchase, do not only look at the appearance of the purchase, check the part number is the best way to reduce the error rate. If you are not clear, please contact us, we are very happy to serve you! || Worth Choice Our product quality is reliable, after-sales guarantee! If you have any questions, please contact us in time, communication is the best way to solve the problem!

CNCJNXW ★Part Name★:3PCS Fuel Injector || ★Part Number★:8971160990 1051481380 || ★Application★:Fits for Isuzu 3LA1 3LB1 Engine || NOTE Please check the part number before purchase, do not only look at the appearance of the purchase, check the part number is the best way to reduce the error rate. If you are not clear, please contact us, we are very happy to serve you! || Worth Choice Our product quality is reliable, after-sales guarantee! If you have any questions, please contact us in time, communication is the best way to solve the problem!

Cross reference number

Zexel num

Bosch num

Firm num

Name

105148-1380

8971160990 ISUZU

NOZZLE AND HOLDER ASSY.

4LC1 K 53KJ NOZZLE & HOLDER ASSY N&NH KCA-P N&NH

4LC1 K 53KJ NOZZLE & HOLDER ASSY N&NH KCA-P N&NH

Information:

It is not necessary to remove the cylinder head assembly for removal of the camshaft.3. Wire the cam roller followers up off of the camshaft as shown. Do this at each cylinder.

Typical Example3. Remove thrust pin (1), and remove camshaft assembly (2) from the engine. The following steps are for the installation of the camshaft assembly.4. Be sure the camshaft assembly is thoroughly clean. Put clean engine oil on the lobes and journals of the camshaft assembly. When installing the camshaft, rotating it in both clockwise and counterclockwise directions will help prevent it from binding in the bearing bores.5. Carefully install camshaft assembly (2) in the engine.

Camshaft Timing

When installing the camshaft assembly, be sure the number one cylinder is at (TDC) top dead center of the compression stroke with the timing pin installed in the flywheel. Camshaft timing is very important. The timing mark on the camshaft drive gear must line up with the idler gear timing mark as shown in the illustration. For more information about timing of engine, refer to the "Specifications" module, Form No. SENR5560.

6. With the camshaft properly timed and positioned, install thrust pin (1). Tighten thrust pin (1) to a torque of 48 7 N m (35 5 lb ft). Remove the wires that were used to hold the cam roller followers up off of the camshaft.End By:a. install front housing groupb. install speed/timing sensorc. install vibration damper and pulleyd. install alternatore. install drive belt and belt tightener groupf. install fuel transfer pumpg. install electronic unit injectorsh. install rocker arm assemblies and push rodsDisassemble & Assemble Camshaft Assembly

Start By:a. remove camshaft assembly1. Wrap camshaft portion of camshaft assembly with paper towels to protect the camshaft from being damaged.

Care must be taken not to allow the camshaft to fall to the floor when pressing it from the drive gear. Also, be sure that a camshaft lobe does not catch on the press plates.

2. Place the camshaft assembly in a press. Press camshaft (3) from drive gear (1).3. Remove woodruff key (2) from the camshaft. The following steps are for the assembly of the camshaft and the gear assembly.4. Install woodruff key (2) in the camshaft.5. Heat drive gear (1) to a maximum temperature of 300 C (572 F) for 30 minutes. Install the drive gear on the end of camshaft (3). Be sure woodruff key (2) is properly aligned and the drive gear makes contact with the shoulder on the end of the camshaft.End By:a. install camshaft assembly

Typical Example3. Remove thrust pin (1), and remove camshaft assembly (2) from the engine. The following steps are for the installation of the camshaft assembly.4. Be sure the camshaft assembly is thoroughly clean. Put clean engine oil on the lobes and journals of the camshaft assembly. When installing the camshaft, rotating it in both clockwise and counterclockwise directions will help prevent it from binding in the bearing bores.5. Carefully install camshaft assembly (2) in the engine.

Camshaft Timing

When installing the camshaft assembly, be sure the number one cylinder is at (TDC) top dead center of the compression stroke with the timing pin installed in the flywheel. Camshaft timing is very important. The timing mark on the camshaft drive gear must line up with the idler gear timing mark as shown in the illustration. For more information about timing of engine, refer to the "Specifications" module, Form No. SENR5560.

6. With the camshaft properly timed and positioned, install thrust pin (1). Tighten thrust pin (1) to a torque of 48 7 N m (35 5 lb ft). Remove the wires that were used to hold the cam roller followers up off of the camshaft.End By:a. install front housing groupb. install speed/timing sensorc. install vibration damper and pulleyd. install alternatore. install drive belt and belt tightener groupf. install fuel transfer pumpg. install electronic unit injectorsh. install rocker arm assemblies and push rodsDisassemble & Assemble Camshaft Assembly

Start By:a. remove camshaft assembly1. Wrap camshaft portion of camshaft assembly with paper towels to protect the camshaft from being damaged.

Care must be taken not to allow the camshaft to fall to the floor when pressing it from the drive gear. Also, be sure that a camshaft lobe does not catch on the press plates.

2. Place the camshaft assembly in a press. Press camshaft (3) from drive gear (1).3. Remove woodruff key (2) from the camshaft. The following steps are for the assembly of the camshaft and the gear assembly.4. Install woodruff key (2) in the camshaft.5. Heat drive gear (1) to a maximum temperature of 300 C (572 F) for 30 minutes. Install the drive gear on the end of camshaft (3). Be sure woodruff key (2) is properly aligned and the drive gear makes contact with the shoulder on the end of the camshaft.End By:a. install camshaft assembly