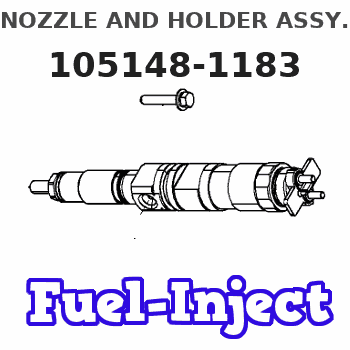

Information nozzle and holder assy.

BOSCH

9 430 610 157

9430610157

ZEXEL

105148-1183

1051481183

MAZDA

PN4013H50C

pn4013h50c

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

4 Pieces Fuel Injectors Compatible With 1971 Bongo 1200 2.5L Part Numbers PN4013H50 PN40-13-H50C PN4013H50C Auto Spare Parts With 3 Month

ZNENJVYB Enjoy a smoother driving experience as these injectors provide fuel delivery, enhancing your vehicle's fuel efficiency and responsiveness on the road. || Benefit from easy installation with a direct fit design, making it simple to replace your old injectors without extensive modifications or tools. || Enhance your vehicle's engine performance and longevity, as these injectors contribute to smoother acceleration and reduced emissions Compatible with a cleaner environment.

ZNENJVYB Enjoy a smoother driving experience as these injectors provide fuel delivery, enhancing your vehicle's fuel efficiency and responsiveness on the road. || Benefit from easy installation with a direct fit design, making it simple to replace your old injectors without extensive modifications or tools. || Enhance your vehicle's engine performance and longevity, as these injectors contribute to smoother acceleration and reduced emissions Compatible with a cleaner environment.

4 Piece Fuel Injector Set Compatible With 1971 Bongo 1200 2.5L PN4013H50 PN40-13-H50C PN4013H50C Auto Spare Parts With

LYUVLBIY Designed Compatible with 1971 Bongo 1200 models, ensuring ideal compatibility Compatible with your vehicle's needs. || Crafted Compatible with performance with a 2.5L engine, boosting your vehicle's efficiency and responsiveness. || Constructed with materials to enhance durability and longevity, offering reliable usage over time. || Includes part numbers PN4013H50, PN40-13-H50C, PN4013H50C Compatible with easy identification and installation. || Sold as a set of 4 fuel injectors, providing a complete replacement solution Compatible with improved fuel delivery.

LYUVLBIY Designed Compatible with 1971 Bongo 1200 models, ensuring ideal compatibility Compatible with your vehicle's needs. || Crafted Compatible with performance with a 2.5L engine, boosting your vehicle's efficiency and responsiveness. || Constructed with materials to enhance durability and longevity, offering reliable usage over time. || Includes part numbers PN4013H50, PN40-13-H50C, PN4013H50C Compatible with easy identification and installation. || Sold as a set of 4 fuel injectors, providing a complete replacement solution Compatible with improved fuel delivery.

4pcs Fuel Injectors Compatible With Mazda Bongo 1200 2.5L PN4013H50 PN40-13-H50C PN4013H50C Auto Spare Accessories W/ 3 Months 1971

KIEUAGYH They can reduce engine noise and vibration levels, providing a smoother driving experience. || Fuel injectors have lower maintenance costs and longer service intervals. || They have high reliability and durabilitySex, can adapt to a long time of use. || Fuel injectors can provide accurate burningOil control to meet different driving needsAnd performance requirements. || They can be adapted to various makes and models of cars, providing better versatility.

KIEUAGYH They can reduce engine noise and vibration levels, providing a smoother driving experience. || Fuel injectors have lower maintenance costs and longer service intervals. || They have high reliability and durabilitySex, can adapt to a long time of use. || Fuel injectors can provide accurate burningOil control to meet different driving needsAnd performance requirements. || They can be adapted to various makes and models of cars, providing better versatility.

You can express buy:

USD 80.05

14-06-2025

14-06-2025

4pcs Diesel injector nozzle set and holder assembly PN40-13-H50C for mazda B2500

USD 100.53

14-06-2025

14-06-2025

4pcs Diesel injector nozzle set and holder assembly PN40-13-H50C for mazda B2500

Images:

USD 82

[28-Apr-2025]

Include in #2:

104700-0530

as NOZZLE AND HOLDER ASSY

Cross reference number

Zexel num

Bosch num

Firm num

Name

105148-1183

PN4013H50C MAZDA

NOZZLE AND HOLDER ASSY.

WLT K 53KJ NOZZLE & HOLDER ASSY N&NH KCA-P N&NH

WLT K 53KJ NOZZLE & HOLDER ASSY N&NH KCA-P N&NH

Information:

1. Remove oil supply tube (1) and suction bell and tube (2). 2. Remove bolts (3) that hold the oil pump to the cylinder block, and remove oil pump (4). The following steps are for installation of the oil pump.3. Put oil pump (4) in position on the cylinder block. Install the bolts that hold the oil pump to the cylinder block.4. Put clean engine oil on the O-ring seals of the tubes.5. Install oil supply tube (1) and suction bell and tube (2).End By:a. install oil panDisassemble Oil Pump

Start By:a. remove oil pump1. Remove the bolt and washer that hold the gear on the shaft. 2. Use tooling (A), and remove drive gear (1) from the shaft. Remove the key from the shaft. 3. Remove retainer (3) for the bypass valve.4. Remove the spring and bypass valve.5. Remove cover (2) from the pump body. 6. Use tooling (B), and remove the bearings from the cover. 7. Remove gears (5) and (6) from pump body (4).8. Use tooling (B), and remove the bearings from pump body (4).Assemble Oil Pump

1. Use tooling (B) to install the bearings in the pump body. Install the bearings so the joint in the bearings is 30° 15° from the center line of the oil pump outlet passage (7). 2. Install idler gear (5) and drive gear (6) in the oil pump body. Put clean engine oil on the bearings and the gears. 3. Use tooling (B), and install the bearings in cover (2). Install the bearings so the joint in the bearings is 30° 15° from the center line of the bearing bores toward oil pump outlet passage (7).4. Install bypass valve (8), spring (9) and the retainer.5. Install the key on the shaft. 6. Install gear (1) on the shaft. Install the washer and bolt that hold the gear on the shaft. Be sure the pump turns freely after assembly.End By:a. install oil pump

Start By:a. remove oil pump1. Remove the bolt and washer that hold the gear on the shaft. 2. Use tooling (A), and remove drive gear (1) from the shaft. Remove the key from the shaft. 3. Remove retainer (3) for the bypass valve.4. Remove the spring and bypass valve.5. Remove cover (2) from the pump body. 6. Use tooling (B), and remove the bearings from the cover. 7. Remove gears (5) and (6) from pump body (4).8. Use tooling (B), and remove the bearings from pump body (4).Assemble Oil Pump

1. Use tooling (B) to install the bearings in the pump body. Install the bearings so the joint in the bearings is 30° 15° from the center line of the oil pump outlet passage (7). 2. Install idler gear (5) and drive gear (6) in the oil pump body. Put clean engine oil on the bearings and the gears. 3. Use tooling (B), and install the bearings in cover (2). Install the bearings so the joint in the bearings is 30° 15° from the center line of the bearing bores toward oil pump outlet passage (7).4. Install bypass valve (8), spring (9) and the retainer.5. Install the key on the shaft. 6. Install gear (1) on the shaft. Install the washer and bolt that hold the gear on the shaft. Be sure the pump turns freely after assembly.End By:a. install oil pump