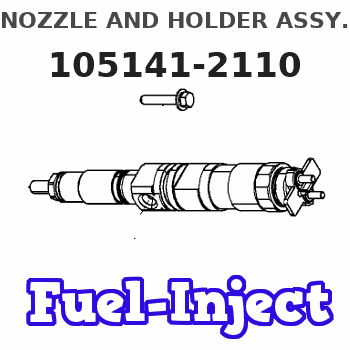

Information nozzle and holder assy.

BOSCH

9 430 610 327

9430610327

ZEXEL

105141-2110

1051412110

Rating:

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Turbocharger

Turbocharger bearing failures can cause large quantities of oil to enter the air intake and exhaust systems. Loss of engine lubricant can result in serious engine damage.Minor leakage of a turbocharger housing under extended low idle operation will not cause problems as long as a turbocharger bearing failure has NOT occurred.When a turbocharger bearing failure is accomplished by a significant engine performance loss (exhaust smoke or engine speed up at no load), DO NOT continue engine operation until the turbocharger is repaired or replaced.

An inspection/check of your turbocharger will minimize unscheduled downtime and reduce the chance for potential damage to other engine parts.Inspect/Check

1. Remove the exhaust outlet and air inlet piping from the turbocharger. Visually check for oil leaks.2. Turn the turbine and compressor wheel by hand. The assembly should turn freely.3. Inspect the turbine wheel and compressor wheel for contact with the turbocharger housing. There should NOT be any visible signs of contact between the turbine or compressor wheels and the turbocharger housing.4. Check the compressor wheel for cleanliness. If only the blade side of the wheel is dirty, dirt and/or moisture is passing through the air filtering system. If oil is found only on the back side of the wheel, it indicates a possible turbocharger oil seal leak.The leak may be the result of extended engine operation at low idle or an intake air line restriction (plugged air filters), which causes the turbocharger to "slobber".* Maintain the compressor wheel/turbine housing by cleaning with standard shop solvents and a soft bristle brush.5. Check the end play and bearing clearance on the turbine wheel and shaft. If the measurements are not within specifications (see the Service Manual), the turbocharger must be repaired or replaced.6. When installing or replacing V-band clamps, position the gap (tightening screw) down if possible so any accumulation of moisture will drain away. Turbocharger components require precision clearances and balancing due to operation at high rotation (torsional) speeds. Severe Service Applications can accelerate component wear and may suggest the need to Inspect/Repair/Replace the cartridge at reduced intervals to ensure maximum reliability and retention of the full core.Removal and Installation

For removal and installation, or repair/replacement options of turbochargers, see your Caterpillar dealer. Refer to the Service Manual for this engine or consult your Caterpillar dealer for the procedure and specifications.Engine Mounts and Crankshaft Vibration Damper

Inspect/Check Engine Mounts

Caterpillar recommends checking the engine mounts for deterioration and proper bolt torque. This will prevent excessive engine vibration caused from improper mounting. See your Service Manual or Caterpillar dealer for recommended torque values.Inspect/Check Camshaft Vibration Damper

Damage to, or failure of the damper will increase torsional vibrations and result in damage to the crankshaft and other engine components. A deteriorating vibration damper will cause excessive gear train noise at variable points in the engine speed range.Rubber Damper

Your engine may be equipped with a standard Rubber Crankshaft Torsional Vibration Damper. A standard damper uses a rubber mounted ring to reduce crankshaft vibration. Some engines also have a Visconic Torsional Vibration Damper. A

Turbocharger bearing failures can cause large quantities of oil to enter the air intake and exhaust systems. Loss of engine lubricant can result in serious engine damage.Minor leakage of a turbocharger housing under extended low idle operation will not cause problems as long as a turbocharger bearing failure has NOT occurred.When a turbocharger bearing failure is accomplished by a significant engine performance loss (exhaust smoke or engine speed up at no load), DO NOT continue engine operation until the turbocharger is repaired or replaced.

An inspection/check of your turbocharger will minimize unscheduled downtime and reduce the chance for potential damage to other engine parts.Inspect/Check

1. Remove the exhaust outlet and air inlet piping from the turbocharger. Visually check for oil leaks.2. Turn the turbine and compressor wheel by hand. The assembly should turn freely.3. Inspect the turbine wheel and compressor wheel for contact with the turbocharger housing. There should NOT be any visible signs of contact between the turbine or compressor wheels and the turbocharger housing.4. Check the compressor wheel for cleanliness. If only the blade side of the wheel is dirty, dirt and/or moisture is passing through the air filtering system. If oil is found only on the back side of the wheel, it indicates a possible turbocharger oil seal leak.The leak may be the result of extended engine operation at low idle or an intake air line restriction (plugged air filters), which causes the turbocharger to "slobber".* Maintain the compressor wheel/turbine housing by cleaning with standard shop solvents and a soft bristle brush.5. Check the end play and bearing clearance on the turbine wheel and shaft. If the measurements are not within specifications (see the Service Manual), the turbocharger must be repaired or replaced.6. When installing or replacing V-band clamps, position the gap (tightening screw) down if possible so any accumulation of moisture will drain away. Turbocharger components require precision clearances and balancing due to operation at high rotation (torsional) speeds. Severe Service Applications can accelerate component wear and may suggest the need to Inspect/Repair/Replace the cartridge at reduced intervals to ensure maximum reliability and retention of the full core.Removal and Installation

For removal and installation, or repair/replacement options of turbochargers, see your Caterpillar dealer. Refer to the Service Manual for this engine or consult your Caterpillar dealer for the procedure and specifications.Engine Mounts and Crankshaft Vibration Damper

Inspect/Check Engine Mounts

Caterpillar recommends checking the engine mounts for deterioration and proper bolt torque. This will prevent excessive engine vibration caused from improper mounting. See your Service Manual or Caterpillar dealer for recommended torque values.Inspect/Check Camshaft Vibration Damper

Damage to, or failure of the damper will increase torsional vibrations and result in damage to the crankshaft and other engine components. A deteriorating vibration damper will cause excessive gear train noise at variable points in the engine speed range.Rubber Damper

Your engine may be equipped with a standard Rubber Crankshaft Torsional Vibration Damper. A standard damper uses a rubber mounted ring to reduce crankshaft vibration. Some engines also have a Visconic Torsional Vibration Damper. A