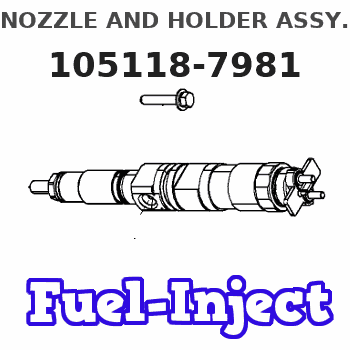

Information nozzle and holder assy.

BOSCH

9 430 613 871

9430613871

ZEXEL

105118-7981

1051187981

NISSAN

16600VG226

16600vg226

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

IMIFAFTAbT 4 PCS Fuel injector 16600-VG226 16600VG226 Fits for Nissan ZD30 3.0 DDTi

IMIFAFTAbT Product Name: 16600-VG226 16600VG226 Fuel injector || Part number: 16600-VG226 16600VG226 || Fits for Nissan ZD30 3.0 DDTi || 4 PCS Fuel injector || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

IMIFAFTAbT Product Name: 16600-VG226 16600VG226 Fuel injector || Part number: 16600-VG226 16600VG226 || Fits for Nissan ZD30 3.0 DDTi || 4 PCS Fuel injector || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

IMIFAFTAbT 1 PCS Fuel injector 16600-VG226 16600VG226 Fits for Nissan ZD30 3.0 DDTi

IMIFAFTAbT Product Name: 16600-VG226 16600VG226 Fuel injector || Part number: 16600-VG226 16600VG226 || Fits for Nissan ZD30 3.0 DDTi || 1 PCS Fuel injector || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

IMIFAFTAbT Product Name: 16600-VG226 16600VG226 Fuel injector || Part number: 16600-VG226 16600VG226 || Fits for Nissan ZD30 3.0 DDTi || 1 PCS Fuel injector || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

Cross reference number

Zexel num

Bosch num

Firm num

Name

16600VG226 NISSAN

NOZZLE AND HOLDER ASSY.

ZD30ETI * C 53LA NOZZLE & HOLDER ASSY N&NH

ZD30ETI * C 53LA NOZZLE & HOLDER ASSY N&NH

A6600VG226 NISSAN

NOZZLE AND HOLDER ASSY.

ZD30ETI A * C 53LA NOZZLE & HOLDER ASSY N&NH

ZD30ETI A * C 53LA NOZZLE & HOLDER ASSY N&NH

Information:

Bridge Adjustment

Intake and Exhaust Valve Mechanism

(1) Adjustment locknut, (2) Exhaust bridge, (3) Adjustment locknut, (4) Intake bridgeThe valve bridge should be checked and/or adjusted each time valve clearance is checked and/or adjusted. Valve and valve mechanism components do not always wear evenly which can allow the bridge to be out of adjustment.It is not necessary to remove the rocker arm shaft to adjust the valve bridges, but there must be clearance. Use the procedure that follows to make an adjustment to the bridge. Valves must be fully closed.1. Remove the valve covers from the engine.2. Lubricate the bridge dowel, bridge bore and the top pad of the bridge assembly with engine oil.3. While firmly pressing straight down on the bridge pad with a force of 1 to 10 lb (0.5 to 4.5 kg), turn the adjusting screw clockwise (CW) until contact is made with the valve stem.4. Turn the adjusting screw clockwise (CW) an additional 45° (1/8 turn) to straighten the dowel in the guide and compensate for slack in the threads.5. Hold the adjusting screw in this position and tighten the adjustment locknut to a torque of 18 5 lb ft (25 7 N m).6. Put engine oil at the point where the rocker arms make contact with the bridges.Valve Lash (Clearance) and Unit Injector Preload Adjustment

Valve clearance is measured between the rocker arm and the bridge for the valves.

Measure the valve lash with the engine stopped. To obtain an accurate measurement, allow at least 20 minutes for the valves to cool to engine cylinder head and block temperature.

When the valve lash (clearance) is checked, an adjustment is NOT necessary if the measurement is within the range given in the "Valve Clearance Check" chart shown. If the measurement is outside of the valve clearance check range shown, an adjustment is necessary. See the "Valve Clearance Setting" chart shown and make the setting to the nominal (desired) specifications in this chart. Adjust the valve clearance to within .003 in ( 0.08 mm) of the value given in the chart above.Rotate the engine crankshaft 360° in the normal crankshaft rotation direction before any adjustments are made. Operation of Caterpillar engines with improper valve adjustments will reduce engine efficiency. This reduced efficiency could result in excessive fuel usage and/or shortened engine component life.

Cylinder and Valve LocationTo make an adjustment to the valve clearance, turn the adjustment screw in the rocker arm. Valve clearance adjustments can be made by using the following procedure. The No. 1 piston must be at top center (TC) on the compression stroke. Follow the first three steps to find top center position for piston No. 1.

Locating Top Center for Piston No. 1

(1) Bolts (two - 6V5219), (2) Cover, (3) Flywheel Housing1. Remove two bolts (1) and remove cover (2) from the flywheel housing (3) to open the turning hole.2. Put one of the 6V5219 bolts in the timing hole located approximately 5 to 6 inches (127 to 152 mm) above the turning hole in

Intake and Exhaust Valve Mechanism

(1) Adjustment locknut, (2) Exhaust bridge, (3) Adjustment locknut, (4) Intake bridgeThe valve bridge should be checked and/or adjusted each time valve clearance is checked and/or adjusted. Valve and valve mechanism components do not always wear evenly which can allow the bridge to be out of adjustment.It is not necessary to remove the rocker arm shaft to adjust the valve bridges, but there must be clearance. Use the procedure that follows to make an adjustment to the bridge. Valves must be fully closed.1. Remove the valve covers from the engine.2. Lubricate the bridge dowel, bridge bore and the top pad of the bridge assembly with engine oil.3. While firmly pressing straight down on the bridge pad with a force of 1 to 10 lb (0.5 to 4.5 kg), turn the adjusting screw clockwise (CW) until contact is made with the valve stem.4. Turn the adjusting screw clockwise (CW) an additional 45° (1/8 turn) to straighten the dowel in the guide and compensate for slack in the threads.5. Hold the adjusting screw in this position and tighten the adjustment locknut to a torque of 18 5 lb ft (25 7 N m).6. Put engine oil at the point where the rocker arms make contact with the bridges.Valve Lash (Clearance) and Unit Injector Preload Adjustment

Valve clearance is measured between the rocker arm and the bridge for the valves.

Measure the valve lash with the engine stopped. To obtain an accurate measurement, allow at least 20 minutes for the valves to cool to engine cylinder head and block temperature.

When the valve lash (clearance) is checked, an adjustment is NOT necessary if the measurement is within the range given in the "Valve Clearance Check" chart shown. If the measurement is outside of the valve clearance check range shown, an adjustment is necessary. See the "Valve Clearance Setting" chart shown and make the setting to the nominal (desired) specifications in this chart. Adjust the valve clearance to within .003 in ( 0.08 mm) of the value given in the chart above.Rotate the engine crankshaft 360° in the normal crankshaft rotation direction before any adjustments are made. Operation of Caterpillar engines with improper valve adjustments will reduce engine efficiency. This reduced efficiency could result in excessive fuel usage and/or shortened engine component life.

Cylinder and Valve LocationTo make an adjustment to the valve clearance, turn the adjustment screw in the rocker arm. Valve clearance adjustments can be made by using the following procedure. The No. 1 piston must be at top center (TC) on the compression stroke. Follow the first three steps to find top center position for piston No. 1.

Locating Top Center for Piston No. 1

(1) Bolts (two - 6V5219), (2) Cover, (3) Flywheel Housing1. Remove two bolts (1) and remove cover (2) from the flywheel housing (3) to open the turning hole.2. Put one of the 6V5219 bolts in the timing hole located approximately 5 to 6 inches (127 to 152 mm) above the turning hole in