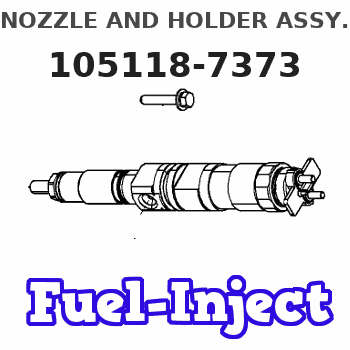

Information nozzle and holder assy.

BOSCH

9 430 613 958

9430613958

ZEXEL

105118-7373

1051187373

ISUZU

8973829450

8973829450

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

New Supply Injector 105118-7373 For Engine High Pressure Fuel Common Rail Injection Valve

EKBMELLJ Effectively reduce the emission of exhaust pollutants, respond to green travel, and easily help vehicles pass monitoring || Equipped with efficient atomization technology, it ensures complete fuel combustion, deeply stimulates the engine's potential, releases powerful performance, and makes driving smoother || Carefully designed, it is compatible with various vehicle models. The installation process is simple and fast, the operation is convenient and worry-free, saving time and energy, and it is easy to use || Made of high-quality materials, it features excellent wear resistance and corrosion resistance, has a long service life, reduces replacement frequency and saves maintenance costs || New High-quality Supply Injector 105118-7373 For Engine High Pressure Fuel Common Rail Injection Valve

EKBMELLJ Effectively reduce the emission of exhaust pollutants, respond to green travel, and easily help vehicles pass monitoring || Equipped with efficient atomization technology, it ensures complete fuel combustion, deeply stimulates the engine's potential, releases powerful performance, and makes driving smoother || Carefully designed, it is compatible with various vehicle models. The installation process is simple and fast, the operation is convenient and worry-free, saving time and energy, and it is easy to use || Made of high-quality materials, it features excellent wear resistance and corrosion resistance, has a long service life, reduces replacement frequency and saves maintenance costs || New High-quality Supply Injector 105118-7373 For Engine High Pressure Fuel Common Rail Injection Valve

fuel injector New Supply Injector 105118-7373 For Engine High Pressure Fuel Common Rail Injection Valve

XEUOOHFX Fast start-up and smooth acceleration, full power, high reliability || High-quality materials, long life, reasonable and safe in production structure, easy to install in original data, comfortable driving without abnormal noise || Improve fuel efficiency, good atomization effect and more sufficient combustion, more accurate fuel injection, and achieve energy-saving and fuel-saving effects || Make emissions meet the standards, burn the residual oil to dry, and reduce black smoke emissions more reasonable, and optimize engine performance for a long time || New High-quality Supply Injector 105118-7373 For Engine High Pressure Fuel Common Rail Injection Valve

XEUOOHFX Fast start-up and smooth acceleration, full power, high reliability || High-quality materials, long life, reasonable and safe in production structure, easy to install in original data, comfortable driving without abnormal noise || Improve fuel efficiency, good atomization effect and more sufficient combustion, more accurate fuel injection, and achieve energy-saving and fuel-saving effects || Make emissions meet the standards, burn the residual oil to dry, and reduce black smoke emissions more reasonable, and optimize engine performance for a long time || New High-quality Supply Injector 105118-7373 For Engine High Pressure Fuel Common Rail Injection Valve

You can express buy:

USD 398.96

13-05-2025

13-05-2025

4PC 095000-8790 Diesel Engine Fuel Common Rail Injector 095000-8791 095000-8793 for DENSO 8-98140249-3 8-97382945-0

Images:

USD 25.27

[01-Jul-2025]

USD 188

[10-Nov-2022]

Include in #2:

104746-5110

as NOZZLE AND HOLDER ASSY

Cross reference number

Zexel num

Bosch num

Firm num

Name

105118-7373

8973829450 ISUZU

NOZZLE AND HOLDER ASSY.

4JB1TC K 53KW NOZZLE & HOLDER ASSY N&NH

4JB1TC K 53KW NOZZLE & HOLDER ASSY N&NH

Information:

Pre-Start Inspection And Procedures

1. Make a "walk-around" inspection of the engine and components for the oil, water or fuel leaks and general appearance. Correct minor adjustments before they develop into major repair jobs.2. Check the crankcase oil level. Maintain the oil level between the ADD and FULL marks on the dipstick. See OIL SPECIFICATIONS for type of oil to use. 3. Check oil level(s) on driven equipment.

Check the engine coolant level when the engine is cool. If the engine is warm, steam may spray outward under high pressure and cause personal injury.

4. Check the engine jacket coolant level. Slowly turn the pressure cap until the cap is removed. Maintain coolant level to the base of the fill pipe. 5. Check the fuel supply. Keep fuel tanks full, as partially filled tanks will collect moisture. See the FUEL SPECIFICATIONS for type of fuel.Keep The Fuel Supply Clean

6. Open the raw water valve on the engine jacket heat exchanger system (if so equipped). Prime the raw water pump if the raw water system has been drained.7. Reset shutoff devices. See the topic, ATTACHMENTS, Emergency Shutoff Devices and Alarms.

OIL PRESSURE RESET

OVERSPEED RESETIf the engine is equipped with an air safety shutoff control, and was tripped to the shutoff position, reset the latch to the run position.

AIR SHUTOFF RESET8. Open the fuel supply valve. If the engine has not run for some time it may be necessary to prime the system. See the topic, PRIMING THE FUEL SYSTEM.9. Disconnect any battery charger which is not protected against starting motor drain.10. Disengage the clutch, or open the circuit breaker on a generator set.

1. Make a "walk-around" inspection of the engine and components for the oil, water or fuel leaks and general appearance. Correct minor adjustments before they develop into major repair jobs.2. Check the crankcase oil level. Maintain the oil level between the ADD and FULL marks on the dipstick. See OIL SPECIFICATIONS for type of oil to use. 3. Check oil level(s) on driven equipment.

Check the engine coolant level when the engine is cool. If the engine is warm, steam may spray outward under high pressure and cause personal injury.

4. Check the engine jacket coolant level. Slowly turn the pressure cap until the cap is removed. Maintain coolant level to the base of the fill pipe. 5. Check the fuel supply. Keep fuel tanks full, as partially filled tanks will collect moisture. See the FUEL SPECIFICATIONS for type of fuel.Keep The Fuel Supply Clean

6. Open the raw water valve on the engine jacket heat exchanger system (if so equipped). Prime the raw water pump if the raw water system has been drained.7. Reset shutoff devices. See the topic, ATTACHMENTS, Emergency Shutoff Devices and Alarms.

OIL PRESSURE RESET

OVERSPEED RESETIf the engine is equipped with an air safety shutoff control, and was tripped to the shutoff position, reset the latch to the run position.

AIR SHUTOFF RESET8. Open the fuel supply valve. If the engine has not run for some time it may be necessary to prime the system. See the topic, PRIMING THE FUEL SYSTEM.9. Disconnect any battery charger which is not protected against starting motor drain.10. Disengage the clutch, or open the circuit breaker on a generator set.