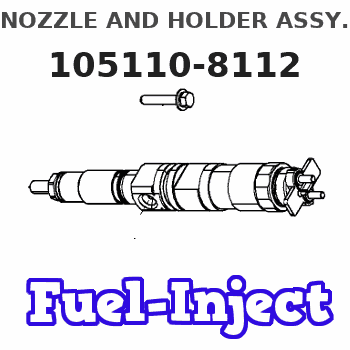

Information nozzle and holder assy.

BOSCH

9 430 613 505

9430613505

ZEXEL

105110-8112

1051108112

ISUZU

1153003891

1153003891

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injector,Compatible With Excavator Diesel Engine Injection Engine Parts 6HK1 Fuel Injector 1-15300389-1 1153003891 Nozzle

CIGFCDGF Fuel Injector,Compatible With Excavator Diesel Engine Injection Engine Parts 6HK1 Fuel Injector 1-15300389-1 1153003891 Nozzle || Operation Function: Precisely controls fuel injection volume and pressure, optimizing injection angle and atomization effect to improve fuel combustion efficiency and ensure engine power output. || Operation Effect: Helps engines run smoothly, reducing abnormal vibrations and noises caused by uneven injection to enhance the stability of construction machinery operations. || Working Compatibility: Suitable for heavy construction machinery such as excavators, supporting high-load excavation and continuous operation to meet the working requirements of engine fuel systems. || Structural Design: Optimizes the internal flow channel and nozzle structure of the fuel injector to improve fuel atomization accuracy, achieving an ideal injection effect and reducing maintenance frequency.

CIGFCDGF Fuel Injector,Compatible With Excavator Diesel Engine Injection Engine Parts 6HK1 Fuel Injector 1-15300389-1 1153003891 Nozzle || Operation Function: Precisely controls fuel injection volume and pressure, optimizing injection angle and atomization effect to improve fuel combustion efficiency and ensure engine power output. || Operation Effect: Helps engines run smoothly, reducing abnormal vibrations and noises caused by uneven injection to enhance the stability of construction machinery operations. || Working Compatibility: Suitable for heavy construction machinery such as excavators, supporting high-load excavation and continuous operation to meet the working requirements of engine fuel systems. || Structural Design: Optimizes the internal flow channel and nozzle structure of the fuel injector to improve fuel atomization accuracy, achieving an ideal injection effect and reducing maintenance frequency.

SPAKYGIE 6Pcs 1153003891 Fuel Injectors fit for Isuzu Engine 6HK1

SPAKYGIE ✨Including:6*Fuel Injectors || ✨Part Number:1-15300389-1, 1-15300-389-1, 1153003891, 9 430 613 505, 9430613505, 105110-8112, 1051108112 || ✨Fits for Isuzu Engine 6HK1 || ✨These parts are manufactured directly from high quality companies. This is a quality set that will last. || ✨Please contact us freely if you have any questions.

SPAKYGIE ✨Including:6*Fuel Injectors || ✨Part Number:1-15300389-1, 1-15300-389-1, 1153003891, 9 430 613 505, 9430613505, 105110-8112, 1051108112 || ✨Fits for Isuzu Engine 6HK1 || ✨These parts are manufactured directly from high quality companies. This is a quality set that will last. || ✨Please contact us freely if you have any questions.

SPAKYGIE 1153003891 Fuel Injector fits for John Deere Excavator 330CLC 370C

SPAKYGIE ✨Including:1*Fuel Injector || ✨Part Number:1-15300389-1, 1-15300-389-1, 1153003891, 9 430 613 505, 9430613505, 105110-8112, 1051108112 || ✨Fits for Isuzu Engine 6HK1 || ✨Fits for John Deere Excavator 330CLC 370C || ✨Please contact us freely if you have any questions.

SPAKYGIE ✨Including:1*Fuel Injector || ✨Part Number:1-15300389-1, 1-15300-389-1, 1153003891, 9 430 613 505, 9430613505, 105110-8112, 1051108112 || ✨Fits for Isuzu Engine 6HK1 || ✨Fits for John Deere Excavator 330CLC 370C || ✨Please contact us freely if you have any questions.

You can express buy:

USD 148.83

13-05-2025

13-05-2025

ZX330 6HK1 Direct Fuel Injector Nozzle 1-15300389-1 for Hitachi Diesel Injector

USD 435.58

13-05-2025

13-05-2025

6HK1 Engine Direct Fuel Injector Nozzle 1-15300389-1 1153003891 For Hitachi ZX330 Excavator

Include in #1:

106671-6450

as NOZZLE AND HOLDER ASSY

Cross reference number

Zexel num

Bosch num

Firm num

Name

105110-8112

1153003891 ISUZU

NOZZLE AND HOLDER ASSY.

6HK1TC K 53KT NOZZLE & HOLDER ASSY N&NH

6HK1TC K 53KT NOZZLE & HOLDER ASSY N&NH

Information:

1W4563, 1W5634 Gear Group

(1) Fuel pump drive gear.(2) Washer. Assemble with large diameter away from gear.(3) Bolt. With the timing pin and timing bolt correctly installed, put a clockwise force of 70 N m (50 lb ft) on the drive gear for the fuel pump and tighten bolt to ... 270 25 N m (200 20 lb ft)(4) Fuel pump idler gear. End play for the idler gear (new) ... 0.10 to 0.41 mm (.004 to .016 in)Maximum permissible end play (worn) ... 0.86 mm (.034 in)Bore in bearing for the idler gear (new) ... 35.004 0.048 mm (1.3781 .0019 in)Diameter of shaft for idler gear (new) ... 34.902 0.020 mm (1.3741 .0008 in)Clearance between shaft and bearing (new) ... 0.033 to 0.168 mm (.0013 to .0066 in)Maximum permissible clearance between shaft and bearing (worn) ... 0.23 mm (.009 in)(5) Plate. Assemble machined side of plate adjacent to the shaft.(6) Bolt. Tighten to ... 25 7 N m (18 5 lb ft)(7) Camshaft gear.(8) Bolts. Tighten to ... 55 7 N m (40 7 lb ft)(9) Crankshaft gear. Maximum temperature of the gear for installation on the crankshaft ... 316°C (600°F)(10) Idler gear for oil pump.(11) Drive gear for oil pump.2P9642 Gear Group

(1) Fuel pump drive gear.(2) Washer. Assemble with large diameter away from gear.(3) Bolt. With the timing pin and timing bolt correctly installed, put a clockwise force of 70 N m (50 lb ft) on the drive gear for the fuel pump and tighten bolt to ... 149 7 N m (110 5 lb ft)(4) Fuel pump idler gear. End play for the idler gear (new) ... 0.10 to 0.41 mm (.004 to .016 in)Maximum permissible end play (worn) ... 0.86 mm (.034 in)Bore in bearing for the idler gear (new) ... 35.004 0.048 mm (1.3781 .0019 in)Diameter of shaft for idler gear (new) ... 34.902 0.020 mm (1.3741 .0008 in)Clearance between shaft and bearing (new) ... 0.033 to 0.168 mm (.0013 to .0066 in)Maximum permissible clearance between shaft and bearing (worn) ... 0.23 mm (.009 in)(5) Plate. Assemble machined side of plate adjacent to the shaft.(6) Bolt. Tighten to ... 25 7 N m (18 5 lb ft)(7) Camshaft gear.(8) Bolts. Tighten to ... 55 7 N m (40 7 lb ft)(9) Crankshaft gear. Maximum temperature of the gear for installation on the crankshaft ... 316°C (600°F)(10) Idler gear for oil pump.(11) Drive gear for oil pump.

(1) Fuel pump drive gear.(2) Washer. Assemble with large diameter away from gear.(3) Bolt. With the timing pin and timing bolt correctly installed, put a clockwise force of 70 N m (50 lb ft) on the drive gear for the fuel pump and tighten bolt to ... 270 25 N m (200 20 lb ft)(4) Fuel pump idler gear. End play for the idler gear (new) ... 0.10 to 0.41 mm (.004 to .016 in)Maximum permissible end play (worn) ... 0.86 mm (.034 in)Bore in bearing for the idler gear (new) ... 35.004 0.048 mm (1.3781 .0019 in)Diameter of shaft for idler gear (new) ... 34.902 0.020 mm (1.3741 .0008 in)Clearance between shaft and bearing (new) ... 0.033 to 0.168 mm (.0013 to .0066 in)Maximum permissible clearance between shaft and bearing (worn) ... 0.23 mm (.009 in)(5) Plate. Assemble machined side of plate adjacent to the shaft.(6) Bolt. Tighten to ... 25 7 N m (18 5 lb ft)(7) Camshaft gear.(8) Bolts. Tighten to ... 55 7 N m (40 7 lb ft)(9) Crankshaft gear. Maximum temperature of the gear for installation on the crankshaft ... 316°C (600°F)(10) Idler gear for oil pump.(11) Drive gear for oil pump.2P9642 Gear Group

(1) Fuel pump drive gear.(2) Washer. Assemble with large diameter away from gear.(3) Bolt. With the timing pin and timing bolt correctly installed, put a clockwise force of 70 N m (50 lb ft) on the drive gear for the fuel pump and tighten bolt to ... 149 7 N m (110 5 lb ft)(4) Fuel pump idler gear. End play for the idler gear (new) ... 0.10 to 0.41 mm (.004 to .016 in)Maximum permissible end play (worn) ... 0.86 mm (.034 in)Bore in bearing for the idler gear (new) ... 35.004 0.048 mm (1.3781 .0019 in)Diameter of shaft for idler gear (new) ... 34.902 0.020 mm (1.3741 .0008 in)Clearance between shaft and bearing (new) ... 0.033 to 0.168 mm (.0013 to .0066 in)Maximum permissible clearance between shaft and bearing (worn) ... 0.23 mm (.009 in)(5) Plate. Assemble machined side of plate adjacent to the shaft.(6) Bolt. Tighten to ... 25 7 N m (18 5 lb ft)(7) Camshaft gear.(8) Bolts. Tighten to ... 55 7 N m (40 7 lb ft)(9) Crankshaft gear. Maximum temperature of the gear for installation on the crankshaft ... 316°C (600°F)(10) Idler gear for oil pump.(11) Drive gear for oil pump.