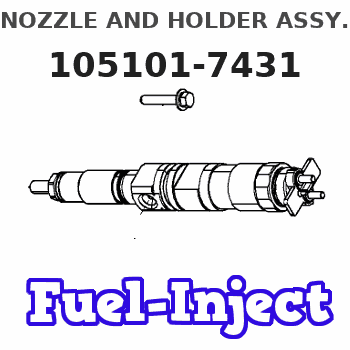

Information nozzle and holder assy.

BOSCH

9 430 611 595

9430611595

ZEXEL

105101-7431

1051017431

ISUZU

1153002941

1153002941

Rating:

Cross reference number

Zexel num

Bosch num

Firm num

Name

105101-7431

1153002941 ISUZU

NOZZLE AND HOLDER ASSY.

12PD1MTC K 53KC NOZZLE & HOLDER ASSY N&NH KBDL2,1-S N&NH

12PD1MTC K 53KC NOZZLE & HOLDER ASSY N&NH KBDL2,1-S N&NH

Information:

Center Bushing Check new bushings using the table below. Commutator and Drive End Bushing Specifications*I.D. of bushing ... 0.6693 to 0.6704 in.(17.000 to 17.028 mm)Oil clearance** ... 0.0036 to 0.0070 in.(0.091 to 0.178 mm)Maximum clearance** ... 0.016 in.(0.41 mm)Bushing depth ... 0.008 to 0.022 in.(0.20 to 0.56 mm)*Reaming may be necessary after installation. Center Bushing SpecificationsI.D. of bushing ... 1.182 to 1.184 in.(30.02 to 30.07 mm)Maximum clearance** ... 0.0236 in.(0.599 mm)Bushing depth ... 0.017 to 0.032 in.(0.43 to 0.81 mm)**The clearance is the difference between the shaft and the I.D. of the bushing.Armature

Check armature for straightness. Runout should not exceed 0.006 inch (0.15 mm). Maximum commutator runout is 0.016 inch (0.41 mm). If necessary, turn commutator and undercut insulation to 1/32-inch (0.794 mm). Undercut should never be less than 0.008 inch (0.20 mm) Commutator O.D. must be 1.77 inches (45.0 mm) or more. Clean copper dust from between the segments.Check armature for opens, shorts and grounds. Burned edge of commutator indicates an open circuit. Short Circuit TestPlace the armature in a growler and hold a hacksaw blade above each slot while slowly rotating the armature. If a coil is shorted, the blade will be attracted to and repelled from the slot.A short circuit most often occurs because of copper dust or filings between two commutator segments. A short of this nature can be corrected by removal of such material.

Fig. 22-Armature Ground TestWith the ohmmeter set to read on its highest scale, place one test lead on the commutator and the other lead on the armature core or shaft (Fig. 22). If the test meter indicator swings towards zero, the armature is grounded. Replace armature.

Fig. 23-Open Circuit TestWith the ohmmeter set to read on its lowest scale, place one test lead on the commutator segment and the other test lead on an adjacent segment (Fig. 23). Repeat this operation for all segments by moving one lead at a time. If the test meter indicator does not swing to zero and remains stationary, the armature coil between these two segements is open. Replace armature.Burned commutator segments are usually an indication of an open circuited coil.Overrunning Clutch and Pinion

Do not immerse the overrunning clutch and pinion 4, Fig. 21 in a cleaning solvent. The unit has been prelubricated and solvent will wash lubricant away. It may be cleaned with a cloth moistened with a cleaning solvent and wiped dry.Rotate the pinion. Pinion gear should rotate smoothly (but not necessarily easily) in one direction, and should not rotate in the opposite direction.If the pinion gear does not rotate smoothly, or if it is worn, chipped, or burred, it should be replaced.Field Windings and Shunt Windings

Grounded Circuit Test (Fig. 24)

Fig. 24-Grounded Circuit TestRemove the screw and hang the eyelet terminal in the air. Using an ohmmeter set to read on its highest scale, place one test lead on the copper terminal bolt and the other lead on a clean spot of the field frame (Fig. 24). If the ohmmeter

Check armature for straightness. Runout should not exceed 0.006 inch (0.15 mm). Maximum commutator runout is 0.016 inch (0.41 mm). If necessary, turn commutator and undercut insulation to 1/32-inch (0.794 mm). Undercut should never be less than 0.008 inch (0.20 mm) Commutator O.D. must be 1.77 inches (45.0 mm) or more. Clean copper dust from between the segments.Check armature for opens, shorts and grounds. Burned edge of commutator indicates an open circuit. Short Circuit TestPlace the armature in a growler and hold a hacksaw blade above each slot while slowly rotating the armature. If a coil is shorted, the blade will be attracted to and repelled from the slot.A short circuit most often occurs because of copper dust or filings between two commutator segments. A short of this nature can be corrected by removal of such material.

Fig. 22-Armature Ground TestWith the ohmmeter set to read on its highest scale, place one test lead on the commutator and the other lead on the armature core or shaft (Fig. 22). If the test meter indicator swings towards zero, the armature is grounded. Replace armature.

Fig. 23-Open Circuit TestWith the ohmmeter set to read on its lowest scale, place one test lead on the commutator segment and the other test lead on an adjacent segment (Fig. 23). Repeat this operation for all segments by moving one lead at a time. If the test meter indicator does not swing to zero and remains stationary, the armature coil between these two segements is open. Replace armature.Burned commutator segments are usually an indication of an open circuited coil.Overrunning Clutch and Pinion

Do not immerse the overrunning clutch and pinion 4, Fig. 21 in a cleaning solvent. The unit has been prelubricated and solvent will wash lubricant away. It may be cleaned with a cloth moistened with a cleaning solvent and wiped dry.Rotate the pinion. Pinion gear should rotate smoothly (but not necessarily easily) in one direction, and should not rotate in the opposite direction.If the pinion gear does not rotate smoothly, or if it is worn, chipped, or burred, it should be replaced.Field Windings and Shunt Windings

Grounded Circuit Test (Fig. 24)

Fig. 24-Grounded Circuit TestRemove the screw and hang the eyelet terminal in the air. Using an ohmmeter set to read on its highest scale, place one test lead on the copper terminal bolt and the other lead on a clean spot of the field frame (Fig. 24). If the ohmmeter