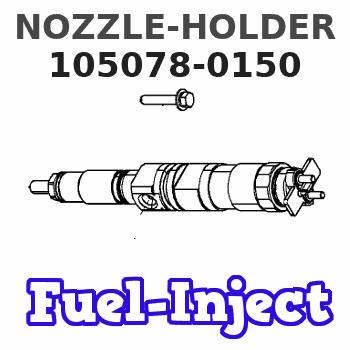

Information nozzle-holder

BOSCH

9 430 615 097

9430615097

ZEXEL

105078-0150

1050780150

ISUZU

8970811590

8970811590

Rating:

Scheme ###:

| 1. | [0] | 150534-2600 | SHIM T0.1 |

| 1. | [0] | 150534-2700 | SHIM T0.2 |

| 1. | [0] | 150534-2800 | SHIM T0.3 |

| 1. | [0] | 150534-2900 | SHIM T0.4 |

| 1. | [0] | 150534-3000 | SHIM T0.5 |

| 1. | [0] | 150534-3100 | SHIM T0.52 |

| 1. | [0] | 150534-3200 | SHIM T0.54 |

| 1. | [0] | 150534-3300 | SHIM T0.56 |

| 1. | [0] | 150534-3400 | SHIM T0.58 |

| 1. | [0] | 150534-3500 | SHIM T0.8 |

| 4. | [1] | 150560-0200 | SLOTTED WASHER |

| 6. | [1] | 150562-4700 | COMPRESSION SPRING |

| 13. | [1] | 150524-4900 | SPACER BUSHING |

| 20. | [1] | 150655-1300 | NOZZLE-RETAINING NUT |

| 800S/1. | [0] | 150534-2600 | SHIM T0.1 |

| 800S/1. | [0] | 150534-2700 | SHIM T0.2 |

| 800S/1. | [0] | 150534-2800 | SHIM T0.3 |

| 800S/1. | [0] | 150534-2900 | SHIM T0.4 |

| 800S/1. | [0] | 150534-3000 | SHIM T0.5 |

| 800S/1. | [0] | 150534-3100 | SHIM T0.52 |

| 800S/1. | [0] | 150534-3200 | SHIM T0.54 |

| 800S/1. | [0] | 150534-3300 | SHIM T0.56 |

| 800S/1. | [0] | 150534-3400 | SHIM T0.58 |

| 800S/1. | [0] | 150534-3500 | SHIM T0.8 |

Include in #2:

104741-5860

as NOZZLE-HOLDER

Cross reference number

Zexel num

Bosch num

Firm num

Name

105078-0150

9 430 615 097

8970811590 ISUZU

NOZZLE-HOLDER

K 53LZ NOZZLE HOLDER NH NH

K 53LZ NOZZLE HOLDER NH NH

Information:

Fuel line clamps should not be over torqued. Over torqueing causes the clamps to butterfly, which results in low clamping force and fuel line vibration and eventual failure.

Tighten fuel line clamps as required using 6V4980 Torque Screwdriver Tool Group. The standard torque for these fasteners (#10 screw) is 20 lb inch (2.26 N m).* Inspect engine wiring and electronic wiring harnesses for loose connections and worn or frayed wires. Inspect:

* Air intake system hoses and elbows for cracks and loose clamps.All guards must be in place.Check condition of batteries and the level of electrolyte, unless equipped with a maintenance free battery.Refer to OEM truck owner manual or manufacturers' recommendations for battery maintenance.Engine Crankcase

Make sure you read and understand the information in the Lubricant Specifications section of this manual before you proceed with maintenance of the crankcase lube oil system.

Check Oil Level

The vehicle must be parked on a level surface to perform this maintenance procedure.

1. Check the oil level with the engine stopped.Ensure that the engine when the oil level is not above the FULL RANGE zone on the dipstick. 2. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the ENGINE STOPPED side of the dipstick. Do not fill the crankcase above the FULL RANGE zone. Operating your engine when the oil level is above the FULL RANGE zone could cause your crankshaft to dip into the oil. If this happens, the air bubbles created from the crankshaft dipping into the oil will reduce the lubricating characteristics of your oil and also result in the loss of power.If the dipstick does not have a FULL mark in the FULL RANGE zone, refer to Dipstick Calibration in this manual or consult your Caterpillar dealer before changing oil and operating the engine. 3. Remove the oil filler cap and add oil if necessary. See Refill Capacities and Lubricant Specifications for the size of your engine crankcase and recommended oil to use. Remote mounted filter or auxiliary filters require additional oil than what the Refill Capacities chart states. For all information pertaining to auxiliary oil filters, refer to the truck OEM or filter manufacturer's instructions.Cooling System

Make sure you read and understand the information in the Cooling System Specifications section of this manual before you proceed with maintenance of the cooling system.

Check Coolant Level

1. Check the coolant level with the engine stopped and cool.2. Remove the filler cap slowly to relieve any pressure.3. Maintain the coolant level within 1/2 inch (13 mm) below the bottom of the fill pipe or to the proper level on the sight glass, if equipped.4. Inspect the filler cap. Replace the cap if gaskets are damaged. Install the filler cap.5. Inspect and clean the radiator fins.Air Cleaner Indicator (If Equipped)

Check Air Cleaner Service Indicator

Typical air cleaner indicator shown.Your engine may be equipped with a different indicator.A service indicator (if equipped) may be mounted on your dashboard or in the engine compartment. A colored piston showing in the window indicates the

Have questions with 105078-0150?

Group cross 105078-0150 ZEXEL

Mazda

Isuzu

105078-0150

9 430 615 097

8970811590

NOZZLE-HOLDER