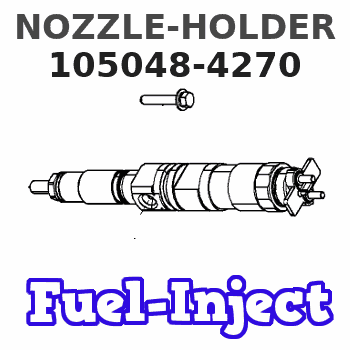

Information nozzle-holder

BOSCH

9 430 615 570

9430615570

ZEXEL

105048-4270

1050484270

NISSAN-DIESEL

1661019D20

1661019d20

Rating:

Scheme ###:

| 8. | [1] | 150562-4300 | COMPRESSION SPRING |

| 10. | [1] | 150560-0400 | SLOTTED WASHER |

| 16. | [2] | 150508-5900 | BEARING PIN |

| 18. | [1] | 150524-4200 | SPACER BUSHING |

| 22. | [1] | 150655-0000 | NOZZLE-RETAINING NUT |

| 800S/1. | [1] | 150591-1000 | SHIM D7.2&3.6T0.10 |

| 800S/1. | [1] | 150591-2000 | SHIM D7.2&3.6T0.20 |

| 800S/1. | [1] | 150591-3000 | SHIM D7.2&3.6T0.30 |

| 800S/1. | [1] | 150591-4000 | SHIM D7.2&3.6T0.40 |

| 800S/1. | [1] | 150591-5000 | SHIM D7.2&3.6T0.50 |

| 800S/1. | [1] | 150591-5100 | SHIM D7.2&3.6T0.51 |

| 800S/1. | [1] | 150591-5200 | SHIM D7.2&3.6T0.52 |

| 800S/1. | [1] | 150591-5300 | SHIM D7.2&3.6T0.53 |

| 800S/1. | [1] | 150591-5400 | SHIM D7.2&3.6T0.54 |

| 800S/1. | [1] | 150591-5500 | SHIM D7.2&3.6T0.55 |

| 800S/1. | [1] | 150591-5600 | SHIM D7.2&3.6T0.56 |

| 800S/1. | [1] | 150591-5700 | SHIM D7.2&3.6T0.57 |

| 800S/1. | [1] | 150591-5800 | SHIM D7.2&3.6T0.58 |

| 800S/1. | [1] | 150591-5900 | SHIM D7.2&3.6T0.59 |

Cross reference number

Zexel num

Bosch num

Firm num

Name

105048-4270

9 430 615 570

1661019D20 NISSAN-DIESEL

NOZZLE-HOLDER

K 53LZ NOZZLE HOLDER NH NH

K 53LZ NOZZLE HOLDER NH NH

Information:

Storage Procedure

When a generator is in storage for any length of time, moisture condenses in the windings. Minimize the condensation by use of a dry storage space and space heaters. Refer to step 2 belowIf a brush-type generator (SRCR) is to be in storage for a year or more, lift the brushes off the slip ring to prevent damage to the slip ring by chemical action.After Storage

Test the main stator windings with a megohmmeter in the following situations: 1. Before initial startup of generator set.2. Every 3 months* if generator is operating in a humid environment.3. If generator has not been run under load for 3 months* or more.*This is a guideline only. It may be necessary to megger more frequently if environment is extremely humid, salty or if the last megger test was close to 1 megohm.The megohmmeter test is described in Service Manuals SENR2180 or SENR7968. A reading of 1 meghom or less indicates that the winding has absorbed too much moisture.To Remove Moisture

To remove moisture caused by high humidity, use one of the following methods to make the generator dry:1. Energize space heaters in generator if so equipped.2. Put the generator in an oven at a temperature of not more than 85°C (185°F) for four hours.

If an oven is used for drying, use a forced air type rather than a radiant type. Radiant ovens can cause localized overheating.

3. Space heaters of the same type used in marine applications, can be installed on generators. (See the Parts Book.) These heaters heat the windings to remove moisture and should be connected at all times in high humidity conditions whenever the generator is not running.4. Use a canvas enclosure around the generator and heating lamps to increase the temperature. Make an opening in the top for release of moisture.5. Send a low voltage current through the windings to increase the temperature of the windings. Do not exceed 85°C (185°F).If the megohmmeter test reads under 1 megohm after the drying or if it goes below 1 megohm shortly after drying, contact your Caterpillar dealer. The insulation has deteriorated and should be reconditioned.

When a generator is in storage for any length of time, moisture condenses in the windings. Minimize the condensation by use of a dry storage space and space heaters. Refer to step 2 belowIf a brush-type generator (SRCR) is to be in storage for a year or more, lift the brushes off the slip ring to prevent damage to the slip ring by chemical action.After Storage

Test the main stator windings with a megohmmeter in the following situations: 1. Before initial startup of generator set.2. Every 3 months* if generator is operating in a humid environment.3. If generator has not been run under load for 3 months* or more.*This is a guideline only. It may be necessary to megger more frequently if environment is extremely humid, salty or if the last megger test was close to 1 megohm.The megohmmeter test is described in Service Manuals SENR2180 or SENR7968. A reading of 1 meghom or less indicates that the winding has absorbed too much moisture.To Remove Moisture

To remove moisture caused by high humidity, use one of the following methods to make the generator dry:1. Energize space heaters in generator if so equipped.2. Put the generator in an oven at a temperature of not more than 85°C (185°F) for four hours.

If an oven is used for drying, use a forced air type rather than a radiant type. Radiant ovens can cause localized overheating.

3. Space heaters of the same type used in marine applications, can be installed on generators. (See the Parts Book.) These heaters heat the windings to remove moisture and should be connected at all times in high humidity conditions whenever the generator is not running.4. Use a canvas enclosure around the generator and heating lamps to increase the temperature. Make an opening in the top for release of moisture.5. Send a low voltage current through the windings to increase the temperature of the windings. Do not exceed 85°C (185°F).If the megohmmeter test reads under 1 megohm after the drying or if it goes below 1 megohm shortly after drying, contact your Caterpillar dealer. The insulation has deteriorated and should be reconditioned.

Have questions with 105048-4270?

Group cross 105048-4270 ZEXEL

Nissan-Diesel

Mitsubishi

Nissan-Diesel

105048-4270

9 430 615 570

1661019D20

NOZZLE-HOLDER