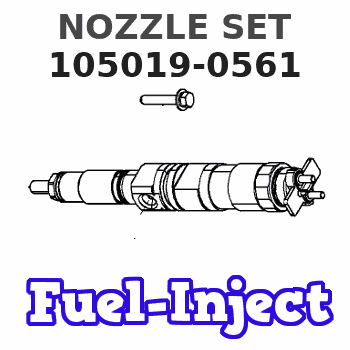

Information nozzle set

BOSCH

9 432 610 787

9432610787

ZEXEL

105019-0561

1050190561

HINO

236601251A

236601251a

Rating:

Include in #1:

107692-3003

as NOZZLE SET

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Machine Specs.

Is stallcondition repeatable Can dealer reproduce?

WaterSeparator / Filter Does the Water Separator / Filter have water in it andwhat is the amount?

Is thegovernor assembly free to operate? Inspect pedal and cables for properoperation and no signs of significant wear or binding

Lowidle speed (no load) rpm

Highidle speed (no load) rpm

Torqueconverter stall speed (engine rpm) Record engine rpm as per RENR3574 Test& Adjust, Transmission and Torque converter testDirect Drive Transmission Arrangement

HP Rating Stall RPM 75 hp 1975 75 RPM 80 hp 2050 75 RPM 85 hp 2075 75 RPM 93 hp 2160 75 RPM Auto shift Transmission Arrangement

HP Rating Stall RPM 75 hp 2068 75 RPM 81 hp 2164 75RPM 90 hp 2206 75 RPM 98 hp 2218 75 RPM Note: Stall speeds are calculated usingNo. 2 diesel fuel.

Turboboost pressure at torque converter stall(full load boost spec is 82 - 85 kPa)

CoolantTemperature (at torque converter stall based on gage reading)

Smokecolor during torque converter stall test (if any) Is the smoke Black, Blue,White or none visible

HydraulicPump Test and Adjust RENR3584 Check for correct system pressure and torquelimiter settings. (Note: this step may be skipped if the dealer can confirmthat the hydraulic system has not been tampered with ? factory settingsare intact.)

Test235-1790 switch for proper operation. Cold advance for FIP, switch openscircuit when the coolant temp reaches 37-43 deg. C and closes at 27-33deg C.

"Wiggle"check electrical connections to and from FIP shutoff solenoid, cold startadvance, and electric lift pump circuit.

Machine Condition

Restrictionsin induction system present Check condition of Air filter and for debrisin the air pre-cleaner.

Restrictionsin exhaust system present?

Blockedfuel tank vent (fuel filler cap)

FuelSystem

SpecificChecks/Tests required Response

Fueltank temperature during either stall condition.

Checkfuel connections, fittings and clips. Check for looseness or fuel leakage.

Lowpressure fuel line interference conditions / restrictions (I.e. check routingof low pressure fuel line). Reference Service Magazine article on low pressurefuel system checks dated 23 Jun 2003.

Aeration(air present in fuel) See RENR2415 Test & Adjust. Air in Fuel ? Test(See illustration 1 for proper installation of clear tube on fuel injectionpump return line).

Fuelflow (low pressure fuel system) See RENR2415 Test & Adjust. Fuel SystemPressure- Test

Doesthe engine perform OK from a separate feed to the FIP? (Suspending a cleancontainer of clean fuel to gravity feed the FIP or fixing a slave liftpump directly to the FIP would eliminate the low pressure circuit on themachine)

Whatwas done to overcome the problem? Illustration 1