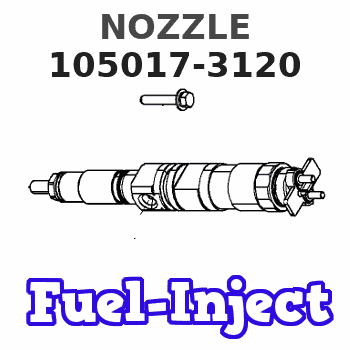

Information nozzle

BOSCH

9 432 612 721

9432612721

ZEXEL

105017-3120

1050173120

MITSUBISHI

ME755426

me755426

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Injector Nozzle 1Set=12Pcs DLLA160PN036 DLLA160PN010 DLLA160PN004 DLLA160P577+ DLLA158PN312 Diesel Pump - (Color: DLLA160P577)

Generic Color: DLLA160P577

Generic Color: DLLA160P577

Diesel Vehicles Special 48-3590 - g Complete DLLA158PN312 / DLLA158PN209 Various Nozzle

Generic

Generic

Diesel Injector Nozzles DLLA158PN312 ME755426 Fits for Mitsubishi Fuso Canter 4D31 4D31T 4pcs/lot

DICSCL PARCS Diesel Injector Nozzles DLLA158PN312 ME755426 fits for Mitsubishi Fuso Canter 4D31 4D31T 4pcs/lot || Fuel Injectors Engine Nozzle Tip Was Designed For Easy Installation With Standard Tools. Always Verify These Diesel Injection System Injector Nozzles Compatibility With Your Vehicle’S Specific Number Firstly || Easy Installation: Fuel Injector No Further Modification To Direct Replacement || Model Number:DLLA158PN312 105017-3120 || Package Include: 4pcs Diesel Injector Nozzle

DICSCL PARCS Diesel Injector Nozzles DLLA158PN312 ME755426 fits for Mitsubishi Fuso Canter 4D31 4D31T 4pcs/lot || Fuel Injectors Engine Nozzle Tip Was Designed For Easy Installation With Standard Tools. Always Verify These Diesel Injection System Injector Nozzles Compatibility With Your Vehicle’S Specific Number Firstly || Easy Installation: Fuel Injector No Further Modification To Direct Replacement || Model Number:DLLA158PN312 105017-3120 || Package Include: 4pcs Diesel Injector Nozzle

You can express buy:

USD 53.47

14-06-2025

14-06-2025

For Mitsubishi Fuso Canter 4D31 4D31T Fuel Injector Nozzle Tips DLLA158PN312 105017-3120

USD 21

01-05-2025

01-05-2025

free shipping 4 pieces Diesel Injectors Nozzle DLLA158PN312 /105017-3120/ 9432612721 Good Quality

Images:

USD 6

[10-Nov-2022]

USD 25

[24-Jun-2019]

USD 5.2

[10-Nov-2022]

Include in #1:

101401-1923

as NOZZLE

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been some isolated instances of issues with the Diesel Particulate Filter (DPF) on certain C3.4B engines.Solution

Caterpillar is aware of this problem. Follow the procedure that is detailed below.

Table 1

Required Tools

Tool Part Number Part Description Qty

A 233-7191 Hose Cleaner Gp 1

Obtain a fuel sample from the engine.

Obtain a lubricating oil sample from the engine.

Attach a copy of the full service history of the engine to the Service Information Systems (SIMSi) report. Include the change history of the following components:

Engine oil

Engine oil filter

Engine fuel filter

Crankcase breather filter

Ensure that the breather element is clean and free from wear or damage. Replace the breather element. Refer to Operation and Maintenance Manual, Engine Crankcase Breather Element - Replace for the correct procedure. Ensure that the inlet hose is clean and free from restriction. If the inlet hose requires replacing, refer to Disassembly and Assembly, Crankcase Breather - Install for the correct procedure.

Determine the service hours of the engine air cleaner element. Ensure that the engine air cleaner element is clean and free from wear, damage, or restriction. If necessary, replace the engine air cleaner element. Refer to Operation and Maintenance Manual, Engine Air Cleaner Element (Single Element) - Inspect/Clean/Replace for the correct procedure. Ensure that the hose assemblies are clean and free from restriction and dust.

Inspect the inlet and outlet hoses of the turbocharger for the presence of excessive lubricating oil. If necessary, take photographs inside both inlet and outlet hoses. If necessary, take photographs inside the compressor housing for the inlet and outlet. If excessive lubricating oil is found, replace the turbocharger. Refer to Disassembly and Assembly, Turbocharger

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been some isolated instances of issues with the Diesel Particulate Filter (DPF) on certain C3.4B engines.Solution

Caterpillar is aware of this problem. Follow the procedure that is detailed below.

Table 1

Required Tools

Tool Part Number Part Description Qty

A 233-7191 Hose Cleaner Gp 1

Obtain a fuel sample from the engine.

Obtain a lubricating oil sample from the engine.

Attach a copy of the full service history of the engine to the Service Information Systems (SIMSi) report. Include the change history of the following components:

Engine oil

Engine oil filter

Engine fuel filter

Crankcase breather filter

Ensure that the breather element is clean and free from wear or damage. Replace the breather element. Refer to Operation and Maintenance Manual, Engine Crankcase Breather Element - Replace for the correct procedure. Ensure that the inlet hose is clean and free from restriction. If the inlet hose requires replacing, refer to Disassembly and Assembly, Crankcase Breather - Install for the correct procedure.

Determine the service hours of the engine air cleaner element. Ensure that the engine air cleaner element is clean and free from wear, damage, or restriction. If necessary, replace the engine air cleaner element. Refer to Operation and Maintenance Manual, Engine Air Cleaner Element (Single Element) - Inspect/Clean/Replace for the correct procedure. Ensure that the hose assemblies are clean and free from restriction and dust.

Inspect the inlet and outlet hoses of the turbocharger for the presence of excessive lubricating oil. If necessary, take photographs inside both inlet and outlet hoses. If necessary, take photographs inside the compressor housing for the inlet and outlet. If excessive lubricating oil is found, replace the turbocharger. Refer to Disassembly and Assembly, Turbocharger