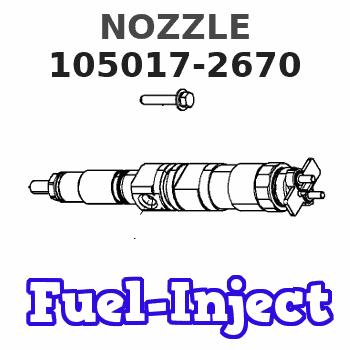

Information nozzle

BOSCH

9 432 610 464

9432610464

ZEXEL

105017-2670

1050172670

KOMATSU

6204113120

6204113120

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$48.68

23 Nov 2024

KR: Adabus

Nozzle Injector DLLA152PN267 Diesel Engine Injector DLLA 152PN267 Fuel Injector Nozzle DLLA152 PN267

Generic

Generic

$6.00

24 Sep 2019

-: -

Diesel nozzle 105017-2670 DLLA152PN267 for 4D95LE-2 Injection nozzle Original assembly

Our products are professionally tested and have good quality.

Our products are professionally tested and have good quality.

You can express buy:

Images:

USD 28

[29-Jan-2019]

Include in #2:

104741-7053

as NOZZLE

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Cleaning the DPF

Because the sections of the DPF are replaceable, a small stock of filter sections can be maintained. Filter sections from a small on-hand stock can be used to replace filters in service at the next scheduled cleaning. The removed filters can be cleaned and returned for installation in the next vehicle. This process of maintaining a stock of filter sections can significantly reduce the amount of down time that will occur.Note: Check State and Local air pollution regulations pertaining to record keeping of serviced filters. Some governmental entities may require filter tracking. Note: Perform a back pressure test prior to cleaning the DPF and record the results. After cleaning the DPF, run the engine at high idle for 5 to 15 minutes to bring the engine and exhaust system to operating temperature. Perform another back pressure test and record the results on the DPF cleaning records form.

Weigh and record the filter unit prior to baking.

By baking the filter under a controlled procedure, the remaining soot on the DPF will burn off and leave a smaller quantity of ash. Failure to observe this procedure can result to damage or cracking to the DPF substrate. A commercial programmable oven is required for this procedure. Careful adherence to this procedure is imperative. Deviation from this procedure may lead to thermal shock and cracking of the DPF substrate or melting at high temperatures.

Place filter into a programmable commercial oven designed for this purpose. Center the filter as much as possible on a rack with 2 inches of spacing below and above for best results.

Program the oven as follows:

Ramp oven temperature to 200° C (392° F)

Hold oven temperature at 200° C (392° F)

Ramp oven temperature to 450° C (842° F)

Hold oven temperature at 450° C (842° F)

Cool down to ambient temperature at natural rate within the oven with the doors closed. Do not use fans.

Place filter in cleaning machine and clean as per machine instructions.

Replace the filter in the oven. Ramp to 650° C (1202° F) in 60 minutes.

Hold oven temperature at 650° C (1202° F) for 240 minutes.

Cool to ambient temperature at a natural rate. Do not use fans.Note: Allow the filter to cool in the oven with the door closed until the filter can be handled with bare hands.Cleaning Procedure

Ash and soot should be removed from the DPF utilizing the Cat 319-2189 Diesel Particulate Filter Cleaner Gp. Using the cleaner without following baking procedure, results in lower efficiency cleaning and will reduce the life of the HEPA filters in the machine. The tool uses pulsed air to flush the ash and soot.Note: Other cleaning methods can release significant quantities of airborne ash and soot. Airborne ash and soot should not be inhaled and may be regulated as a hazardous substance by local regulations.Cleaned Filter Specification

The following steps determine if the DPF was properly cleaned:Note: This specification applies to filters that were cleaned of ash only. This specification is only valid subsequent to the recommend

Because the sections of the DPF are replaceable, a small stock of filter sections can be maintained. Filter sections from a small on-hand stock can be used to replace filters in service at the next scheduled cleaning. The removed filters can be cleaned and returned for installation in the next vehicle. This process of maintaining a stock of filter sections can significantly reduce the amount of down time that will occur.Note: Check State and Local air pollution regulations pertaining to record keeping of serviced filters. Some governmental entities may require filter tracking. Note: Perform a back pressure test prior to cleaning the DPF and record the results. After cleaning the DPF, run the engine at high idle for 5 to 15 minutes to bring the engine and exhaust system to operating temperature. Perform another back pressure test and record the results on the DPF cleaning records form.

Weigh and record the filter unit prior to baking.

By baking the filter under a controlled procedure, the remaining soot on the DPF will burn off and leave a smaller quantity of ash. Failure to observe this procedure can result to damage or cracking to the DPF substrate. A commercial programmable oven is required for this procedure. Careful adherence to this procedure is imperative. Deviation from this procedure may lead to thermal shock and cracking of the DPF substrate or melting at high temperatures.

Place filter into a programmable commercial oven designed for this purpose. Center the filter as much as possible on a rack with 2 inches of spacing below and above for best results.

Program the oven as follows:

Ramp oven temperature to 200° C (392° F)

Hold oven temperature at 200° C (392° F)

Ramp oven temperature to 450° C (842° F)

Hold oven temperature at 450° C (842° F)

Cool down to ambient temperature at natural rate within the oven with the doors closed. Do not use fans.

Place filter in cleaning machine and clean as per machine instructions.

Replace the filter in the oven. Ramp to 650° C (1202° F) in 60 minutes.

Hold oven temperature at 650° C (1202° F) for 240 minutes.

Cool to ambient temperature at a natural rate. Do not use fans.Note: Allow the filter to cool in the oven with the door closed until the filter can be handled with bare hands.Cleaning Procedure

Ash and soot should be removed from the DPF utilizing the Cat 319-2189 Diesel Particulate Filter Cleaner Gp. Using the cleaner without following baking procedure, results in lower efficiency cleaning and will reduce the life of the HEPA filters in the machine. The tool uses pulsed air to flush the ash and soot.Note: Other cleaning methods can release significant quantities of airborne ash and soot. Airborne ash and soot should not be inhaled and may be regulated as a hazardous substance by local regulations.Cleaned Filter Specification

The following steps determine if the DPF was properly cleaned:Note: This specification applies to filters that were cleaned of ash only. This specification is only valid subsequent to the recommend