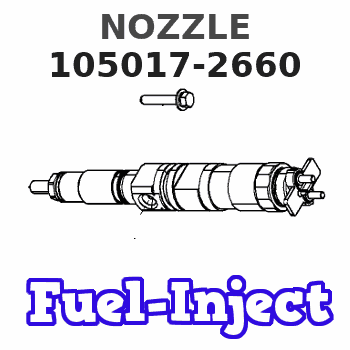

Information nozzle

BOSCH

9 432 610 462

9432610462

ZEXEL

105017-2660

1050172660

KOMATSU

6205113120

6205113120

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

105017-2660 Fuel Injection Nozzle 8Pcs

DFGUFG [Product compatibility]: The OE number of this product is 105017-2660 || [Enhanced Fuel Efficiency & Power Output: Precision-engineered fuel injectors optimize spray patterns for improved combustion efficiency, directly boosting mileage while maintaining stable engine performance across all RPM ranges || [Easy to install and affordable]: Each fuel injector meets factory standard specifications, is simple and convenient to install, has higher combustion efficiency, and can effectively reduce fuel consumption || [High-quality materials for better performance]: The injectors are made of high-quality materials and advanced manufacturing processes to ensure durability and service life, allowing your engine to run smoothly for a long time || [Guaranteed Engine Performance]: This product is one of the key components of electronic fuel injection engines, helping to improve engine performance

DFGUFG [Product compatibility]: The OE number of this product is 105017-2660 || [Enhanced Fuel Efficiency & Power Output: Precision-engineered fuel injectors optimize spray patterns for improved combustion efficiency, directly boosting mileage while maintaining stable engine performance across all RPM ranges || [Easy to install and affordable]: Each fuel injector meets factory standard specifications, is simple and convenient to install, has higher combustion efficiency, and can effectively reduce fuel consumption || [High-quality materials for better performance]: The injectors are made of high-quality materials and advanced manufacturing processes to ensure durability and service life, allowing your engine to run smoothly for a long time || [Guaranteed Engine Performance]: This product is one of the key components of electronic fuel injection engines, helping to improve engine performance

$20.99

08 Nov 2024

KR: Adabus

DLLA160PN141 DLLA152PN284 DLLA148PN266 DLLA140PN291 DLLA152PN009 DLLA145PN238 DLLA153PN152 DSLA150PN926 Diesel Nozzle - (Color: DLLA148PN266)

Generic Color: DLLA148PN266 || Special features: no || Material type: STEEL || Item weight: 0.03 || Item height: standard

Generic Color: DLLA148PN266 || Special features: no || Material type: STEEL || Item weight: 0.03 || Item height: standard

Include in #1:

101495-3422

as NOZZLE

Include in #2:

104741-7062

as NOZZLE

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Ensure that all components are free of contaminants before installing. Contaminants may cause premature wear and reduced component service life.

Note: Disposition and Recycling - Common components of exhaust aftertreatment devices include, but are not limited to, cordierite, silicon carbide, iron zeolite, vanadium, platinum, and palladium. After the devices are used in an engine exhaust flow they can include some by-products that result from combustion. Follow applicable Federal, State, and local regulations when handling or discarding used aftertreatment devices

Illustration 1 g03842051

Note: Prior to removal of the catalyst, identify the position of the catalysts and airflow direction. Ensure that the catalyst part number position and the air flow direction remain the same.

Remove Diesel Particulate Filter (DPF) hatch cover (1) nuts, bolts, and washers.

Remove hatch cover (1) from the reactor unit.

Remove gasket assembly from the sealing surface of the hatch cover.

Carefully remove DPF catalyst assembly by removing the V band clamps. If necessary, repeat for other PDF catalysts. Take note of DPF air flow direction and location for reassembly.

Carefully install DPF catalyst into the cabinet with new gaskets. Verify correct position and air flow direction of the DPF.

DPF should always be installed in the direction shown in illustration 1. The long end of the DPF should be installed in the sleeve of the reactor and secured with the proper V band clamps.

For verified applications, replacement DPFs must have the proper tags and meet all documentation requirements.

Apply final torque to V band clamps. Refer to Specifications, SENR3130, "Torque Specifications" for the proper torque.

Replace all inner backing strip gaskets on the DPF catalyst cover.

Install DPF cover assembly.

Replace all damaged bolts.

Apply final torque to all bolts in a circular pattern. Refer to Specifications, SENR3130, "Torque Specifications" for the proper torque.

Verify that all bolts are at the proper torque value.