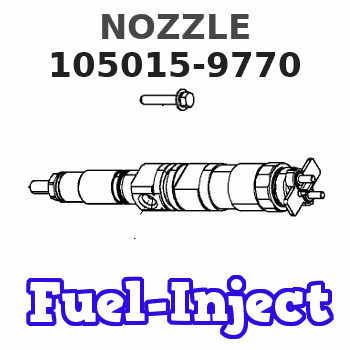

Information nozzle

BOSCH

9 432 611 416

9432611416

ZEXEL

105015-9770

1050159770

MITSUBISHI

ME731935

me731935

Rating:

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Reasonable travel time and mileage will be allowed.

Up to $350 will be allowed for man lift rental to access the injector group.

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 2*******

0-500 hrs,

0-12 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 2.0-hour job for Group 2

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

For Group 1 Only:

Step 1: Ensure CEM has cooled prior to beginning work. Use a temp gun to ensure that the temperature of the injector is at a safe to handle temperature.

Image1.1.1

Step 2: Once the CEM is at a safe temperature to begin work, remove air and DEF line connections at the injector. Ensure all permits and appropriate scaffolding or man-lift type equipment with sufficient personnel are on site or available if needed. This procedure may require two individuals with all the required PPE to handle the weight and distance to reach for work to be performed.

Image1.2.1

Step 3: Remove eight bolts and remove injector assembly from the CEM. This step may require two individuals due to the weight of the injector.

Step 4: Remove the nozzle group from the injector.

Image1.4.1

Step 5: Apply Loctite (nickel free) dry film anti-seize on the threads of the 352-0865 nozzle group. Ensure that only the threads receive anti-seize as the nozzle could suffer plugging if anti-seize contaminates the tip. Install the nozzle group with a new gasket onto the injector group and tighten to 9 +/- 2 Nm.

Image1.5.1

Step 6: Reinstall the injector with new nozzle and new gasket into the CEM matching alignment notches and tighten the eight (8) mounting bolts to standard torque. This step may require two individuals due to the weight of the injector.

Image1.6.1

Step 7: Using a stamping die set, the old injector part number must be removed. This can be accomplished using the X stamp and stamping out all of the part numbers (XXXXXXXX) or a grinder can be used to permanently remove the part number.

Step 8: Using the stamping die set, stamp part number 549-2925 on the flange of the injector as shown in image 1.6.1.

Step 9: Install software part number 549-6259 into the dosing cabinet ECM.

Please note that re-commissioning of the SCR system is not required after the software update if the system has already been commissioned.