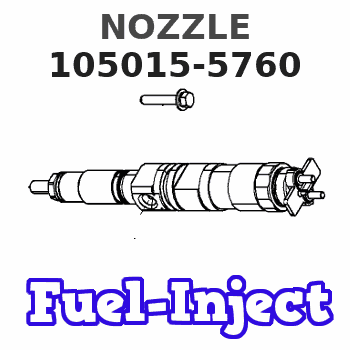

Information nozzle

BOSCH

9 432 611 830

9432611830

ZEXEL

105015-5760

1050155760

NIIGATA-URAWA

U2C32300A

u2c32300a

Rating:

Include in #1:

106671-4032

as NOZZLE

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Coolant is essential to control engine operating temperatures and make components last longer. Poorly maintained coolant can actually shorten component life by causing a chain reaction of heat problems. Excessive heat can cause: * Hot spots that crack steel, notably in cylinder heads* Bubble pockets that form on cylinder surfaces and result in liner pitting* Oil to degrade, leading to component damage* Lacquer and shellac build-up on precision hydraulic parts* Oil additives to break down and transmission clutches to slipS O S Coolant Analysis is the best way to monitor the condition of your coolant and your cooling system. The two-level program, based on samples you submit, shows the condition of coolant and the cooling system.Level I: Basic Coolant Maintenance Check

Checks for correct chemical balance for proper heat and corrosion control. Tests for: * glycol* SCA concentrations* pH* conductivityS O S Coolant Analysis reports results and makes recommendations, usually within 24 hours. Consult with your Caterpillar dealer for more information.The concentration of SCA should be checked regularly for over or under concentration. This should be done with the 4C-9301 Test Kit or the 8T-5296 Test Kit or S O S Coolant Analysis (Level I) at the Every 250 Hours interval.Further coolant analysis is recommended at twice a year or after every 1000 service hours.For example, suppose considerable deposits are found in the water jacket areas on the external cooling system, yet coolant additive concentrations were carefully maintained. Chances are that the coolant water had minerals which deposited on the engine over time.One way to verify the water condition, or to be sure of new water at fill time, is to have a coolant analysis conducted. Full water analysis can sometimes be obtained locally by contacting your local water utility company or an agricultural agent. Private laboratories are also available.Caterpillar recommends S O S Level II Coolant Analysis.Level II: Comprehensive Cooling System Analysis

Completely analyzes coolant and coolant effects on the cooling system. Level II Coolant Analysis provides: * full Level I analysis* visual properties inspection* metal corrosion and contaminant identification* identification of built-up impurities that point to corrosion and scaling problems BEFORE they lead to costly repairsLevel II Coolant Analysis provides a simple, clear report of results, and makes recommendations for the lowest cost corrective options.For more information on coolant analysis and how it can help you manage your equipment, see your Caterpillar dealer.

Checks for correct chemical balance for proper heat and corrosion control. Tests for: * glycol* SCA concentrations* pH* conductivityS O S Coolant Analysis reports results and makes recommendations, usually within 24 hours. Consult with your Caterpillar dealer for more information.The concentration of SCA should be checked regularly for over or under concentration. This should be done with the 4C-9301 Test Kit or the 8T-5296 Test Kit or S O S Coolant Analysis (Level I) at the Every 250 Hours interval.Further coolant analysis is recommended at twice a year or after every 1000 service hours.For example, suppose considerable deposits are found in the water jacket areas on the external cooling system, yet coolant additive concentrations were carefully maintained. Chances are that the coolant water had minerals which deposited on the engine over time.One way to verify the water condition, or to be sure of new water at fill time, is to have a coolant analysis conducted. Full water analysis can sometimes be obtained locally by contacting your local water utility company or an agricultural agent. Private laboratories are also available.Caterpillar recommends S O S Level II Coolant Analysis.Level II: Comprehensive Cooling System Analysis

Completely analyzes coolant and coolant effects on the cooling system. Level II Coolant Analysis provides: * full Level I analysis* visual properties inspection* metal corrosion and contaminant identification* identification of built-up impurities that point to corrosion and scaling problems BEFORE they lead to costly repairsLevel II Coolant Analysis provides a simple, clear report of results, and makes recommendations for the lowest cost corrective options.For more information on coolant analysis and how it can help you manage your equipment, see your Caterpillar dealer.