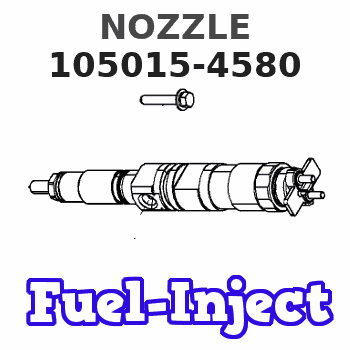

Information nozzle

BOSCH

9 432 610 345

9432610345

ZEXEL

105015-4580

1050154580

MITSUBISHI

ME066035

me066035

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

12 Pcs Diesel Fuel Injector Nozzle DLLA162S384N457 105015-4570 DLLA155S365N458 105015-4580 DLLA150S374N464 105015-(105015-4580)

EKBMELLJ Effectively reduce the emission of exhaust pollutants, respond to green travel, and easily help vehicles pass monitoring || Equipped with efficient atomization technology, it ensures complete fuel combustion, deeply stimulates the engine's potential, releases powerful performance, and makes driving smoother || Carefully designed, it is compatible with various vehicle models. The installation process is simple and fast, the operation is convenient and worry-free, saving time and energy, and it is easy to use || Made of high-quality materials, it features excellent wear resistance and corrosion resistance, has a long service life, reduces replacement frequency and saves maintenance costs || 12 Pcs High Quality Diesel Fuel Injector Nozzle DLLA162S384N457 105015-4570 DLLA155S365N458 105015-4580 DLLA150S374N464 105015-

EKBMELLJ Effectively reduce the emission of exhaust pollutants, respond to green travel, and easily help vehicles pass monitoring || Equipped with efficient atomization technology, it ensures complete fuel combustion, deeply stimulates the engine's potential, releases powerful performance, and makes driving smoother || Carefully designed, it is compatible with various vehicle models. The installation process is simple and fast, the operation is convenient and worry-free, saving time and energy, and it is easy to use || Made of high-quality materials, it features excellent wear resistance and corrosion resistance, has a long service life, reduces replacement frequency and saves maintenance costs || 12 Pcs High Quality Diesel Fuel Injector Nozzle DLLA162S384N457 105015-4570 DLLA155S365N458 105015-4580 DLLA150S374N464 105015-

12 Pcs Diesel Fuel Injector Nozzle DLLA162S384N457 105015-4570 DLLA155S365N458 105015-4580 DLLA150S374N464 105015-(105015-4640)

EKBMELLJ Effectively reduce the emission of exhaust pollutants, respond to green travel, and easily help vehicles pass monitoring || Equipped with efficient atomization technology, it ensures complete fuel combustion, deeply stimulates the engine's potential, releases powerful performance, and makes driving smoother || Carefully designed, it is compatible with various vehicle models. The installation process is simple and fast, the operation is convenient and worry-free, saving time and energy, and it is easy to use || Made of high-quality materials, it features excellent wear resistance and corrosion resistance, has a long service life, reduces replacement frequency and saves maintenance costs || 12 Pcs High Quality Diesel Fuel Injector Nozzle DLLA162S384N457 105015-4570 DLLA155S365N458 105015-4580 DLLA150S374N464 105015-

EKBMELLJ Effectively reduce the emission of exhaust pollutants, respond to green travel, and easily help vehicles pass monitoring || Equipped with efficient atomization technology, it ensures complete fuel combustion, deeply stimulates the engine's potential, releases powerful performance, and makes driving smoother || Carefully designed, it is compatible with various vehicle models. The installation process is simple and fast, the operation is convenient and worry-free, saving time and energy, and it is easy to use || Made of high-quality materials, it features excellent wear resistance and corrosion resistance, has a long service life, reduces replacement frequency and saves maintenance costs || 12 Pcs High Quality Diesel Fuel Injector Nozzle DLLA162S384N457 105015-4570 DLLA155S365N458 105015-4580 DLLA150S374N464 105015-

12 Pcs Diesel Fuel Injector Nozzle DLLA162S384N457 105015-4570 DLLA155S365N458 105015-4580 DLLA150S374N464 105015-(105015-4640)

SKDKVUGC Constructed from high - strength and corrosion - resistant alloy materials, this product is designed to extend its service life. || It has the ability to spray fuel in an extremely fine particle state. This allows for thorough mixing with air, enabling efficient combustion and enhancing fuel economy. || It can adapt to diverse working conditions. Whether the vehicle is idling, accelerating, or traveling at high speeds, it is capable of achieving precise fuel injection. || Manufactured with high precision, it makes use of advanced processing techniques. This ensures the dimensional accuracy and performance consistency of fuel injectors. || 12 Pcs High Quality Diesel Fuel Injector Nozzle DLLA162S384N457 105015-4570 DLLA155S365N458 105015-4580 DLLA150S374N464 105015-

SKDKVUGC Constructed from high - strength and corrosion - resistant alloy materials, this product is designed to extend its service life. || It has the ability to spray fuel in an extremely fine particle state. This allows for thorough mixing with air, enabling efficient combustion and enhancing fuel economy. || It can adapt to diverse working conditions. Whether the vehicle is idling, accelerating, or traveling at high speeds, it is capable of achieving precise fuel injection. || Manufactured with high precision, it makes use of advanced processing techniques. This ensures the dimensional accuracy and performance consistency of fuel injectors. || 12 Pcs High Quality Diesel Fuel Injector Nozzle DLLA162S384N457 105015-4570 DLLA155S365N458 105015-4580 DLLA150S374N464 105015-

You can express buy:

Images:

US $5.00

[26-Apr-2017]

Include in #1:

106861-2000

as NOZZLE

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Caterpillar Diesel Engines can operate effectively in cold weather. However, engine operation in cold weather is dependent on the type of fuel used and how well the fuel moves through fuel related components. The purpose of this section is to explain some of the problems and steps that can be taken to minimize fuel problems during cold weather operation, when the engine area is colder than 5°C (40°F).Fuel and the Effect from Cold Weather

The two types of diesel fuel available for your engine are typically grades No. 1 and No. 2. No. 2 diesel fuel is the most commonly used fuel. No. 1 diesel fuel, or a blend of No. 1 and No. 2, is best suited for cold weather operation.Quantities of No. 1 diesel fuel are limited, and generally only available during the winter months in the colder climates. During cold weather operation, if No. 1 fuel is unavailable, it may be necessary to use No. 2 diesel fuel.There are three major differences between No. 1 and No. 2 diesel fuel. No. 1 diesel fuel has: * a lower cloud point* a lower pour point* a lower BTU (kJ) (heat content) rating per unit volume of fuel than the average No. 2 diesel fuel.When using No. 1 diesel fuel, you may notice a drop in power and fuel efficiency. You should not experience any other operating effects.The cloud point is the temperature at which a cloud or haze of wax crystals begins to form in the fuel and cause fuel filters to plug. The pour point is the temperature which diesel fuel begins to thicken and be more resistant to flow through fuel pumps and lines.Be aware of these fuel values when purchasing your diesel fuel. Anticipate the average outside (ambient) temperature for the area your engine will be operating. Engines fueled in one climate may not operate satisfactorily if moved to another because of problems that result from cold weather.Before troubleshooting for low power or poor performance in winter months, check the type of fuel being used.When No. 2 diesel fuel is used: starting aids, engine oil pan heaters, engine coolant heaters, fuel heaters, and fuel line insulation also provide a means of minimizing starting and fuel problems in cold weather.Fuel Related Components in Cold Weather

Fuel Tanks

Condensation can form in partially filled fuel tanks. Top off fuel tanks before leaving overnight.Fuel tanks should contain some provision for draining water and sediment from the bottom of the tanks. Some fuel tanks use supply pipes that allow water and sediment to settle below the end of the fuel supply pipe.Some fuel tanks use supply lines that take fuel directly from the bottom of the tank. If equipped with this system, regular maintenance of the fuel system filter(s) is important.Check the fuel level in the day tank daily by observing the sight gauge. Drain the water and sediment from any fuel storage tank weekly, at the oil change period, and before the fuel tank is refilled. This will help

The two types of diesel fuel available for your engine are typically grades No. 1 and No. 2. No. 2 diesel fuel is the most commonly used fuel. No. 1 diesel fuel, or a blend of No. 1 and No. 2, is best suited for cold weather operation.Quantities of No. 1 diesel fuel are limited, and generally only available during the winter months in the colder climates. During cold weather operation, if No. 1 fuel is unavailable, it may be necessary to use No. 2 diesel fuel.There are three major differences between No. 1 and No. 2 diesel fuel. No. 1 diesel fuel has: * a lower cloud point* a lower pour point* a lower BTU (kJ) (heat content) rating per unit volume of fuel than the average No. 2 diesel fuel.When using No. 1 diesel fuel, you may notice a drop in power and fuel efficiency. You should not experience any other operating effects.The cloud point is the temperature at which a cloud or haze of wax crystals begins to form in the fuel and cause fuel filters to plug. The pour point is the temperature which diesel fuel begins to thicken and be more resistant to flow through fuel pumps and lines.Be aware of these fuel values when purchasing your diesel fuel. Anticipate the average outside (ambient) temperature for the area your engine will be operating. Engines fueled in one climate may not operate satisfactorily if moved to another because of problems that result from cold weather.Before troubleshooting for low power or poor performance in winter months, check the type of fuel being used.When No. 2 diesel fuel is used: starting aids, engine oil pan heaters, engine coolant heaters, fuel heaters, and fuel line insulation also provide a means of minimizing starting and fuel problems in cold weather.Fuel Related Components in Cold Weather

Fuel Tanks

Condensation can form in partially filled fuel tanks. Top off fuel tanks before leaving overnight.Fuel tanks should contain some provision for draining water and sediment from the bottom of the tanks. Some fuel tanks use supply pipes that allow water and sediment to settle below the end of the fuel supply pipe.Some fuel tanks use supply lines that take fuel directly from the bottom of the tank. If equipped with this system, regular maintenance of the fuel system filter(s) is important.Check the fuel level in the day tank daily by observing the sight gauge. Drain the water and sediment from any fuel storage tank weekly, at the oil change period, and before the fuel tank is refilled. This will help